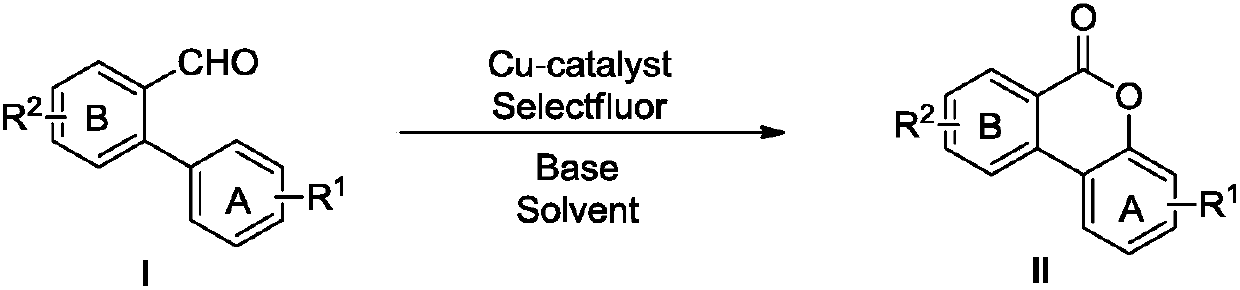

Method for synthesizing of isocoumarin compounds

A technology of isocoumarin and compounds, applied in the direction of organic chemistry, can solve the problems of expensive o-hydroxyphenylboronic acid, narrow application range, harsh reaction conditions, etc., and achieve the effect of simple reaction steps, simple operation and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

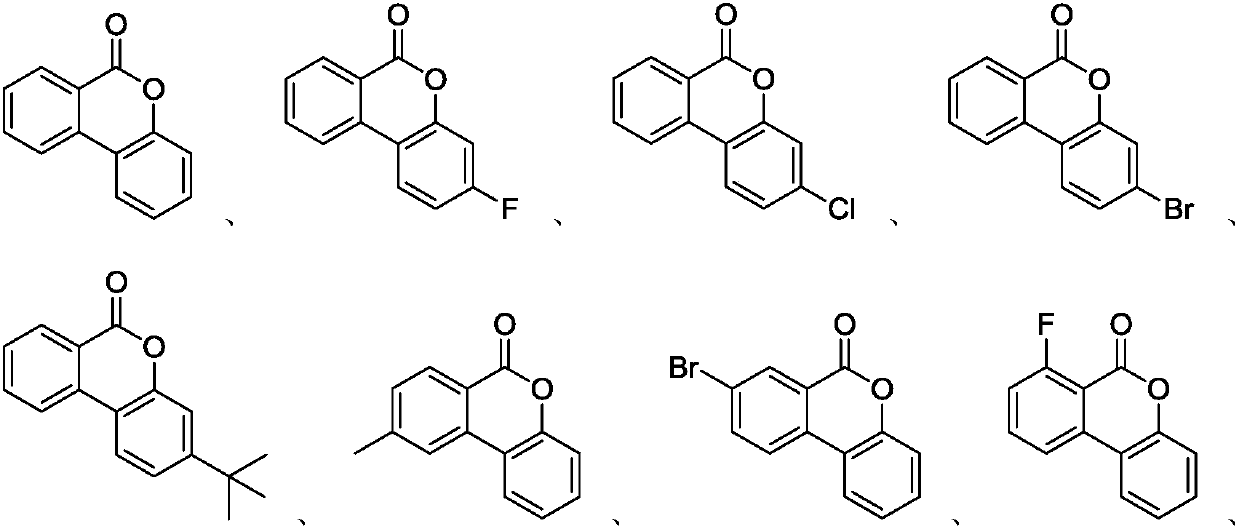

Examples

Embodiment 1

[0033]

[0034] 0.3mmol 2-phenylbenzaldehyde (54.6mg), 0.03mmol Cu powder (1.92mg), 0.6mmol Selectfluor (212.4mg) and 0.45mmol K 2 CO 3 (62.1mg) was added to a 15mL thick-walled pressure-resistant reaction tube, and then 3mL of acetonitrile was added as a solvent. Then, it was stirred magnetically at 25°C for 24 hours. After cooling to room temperature, 10 mL of water was added, and extracted with dichloromethane (3*10 mL), the organic phases were combined and washed with anhydrous Na 2 SO 4 After drying, the filtrate was taken by suction filtration to remove the solvent, and then separated by silica gel column chromatography, using petroleum ether / ethyl acetate = 30:1 as the eluent, collecting the eluate containing the target product and evaporating the solvent to obtain benzisocoumarin . The material was a white solid in 86% yield.

[0035] Characterization data: IR(KBr,cm -1 ):ν=1733,1602; 1 H NMR (500MHz, CDCl 3 ):δ8.43(dd,J 1 =7.5Hz,J 2 =1.0Hz,1H),8.15(d,J=8....

Embodiment 2

[0037]

[0038] 0.3mmol 2-phenylbenzaldehyde (54.6mg), 0.03mmol Cu powder (1.92mg), 0.45mmol Selectfluor (159.4mg) and 0.75mmol K 2 CO 3 (103.5 mg) was added to a 15 mL thick-walled pressure-resistant reaction tube, and then 3 mL of acetonitrile was added as a solvent. Then, it was magnetically stirred at 50° C. for 6 hours. After cooling to room temperature, 10 mL of water was added, extracted with dichloromethane (3*10 mL), the organic phases were combined and washed with anhydrous Na 2 SO 4 Dry, and then filter the filtrate to remove the solvent, then separate it by silica gel column chromatography, use petroleum ether / ethyl acetate = 30:1 as the eluent, collect the eluate containing the target product and evaporate the solvent to obtain benzoisocoumarin white. The material was a white solid in 76% yield.

[0039] Characterization data: IR(KBr,cm -1 ):ν=1733,1602; 1 H NMR (500MHz, CDCl 3 ):δ8.43(dd,J 1 =7.5Hz,J 2=1.0Hz,1H),8.15(d,J=8.5Hz,1H),8.09(dd,J 1 =8.0Hz...

Embodiment 3

[0041]

[0042] 0.3mmol 2-phenylbenzaldehyde (54.6mg), 0.015mmol Cu powder (0.96mg), 0.75mmol Selectfluor (265.7mg) and 0.9mmol K 2 CO 3 (124.2 mg) was added to a 15 mL thick-walled pressure-resistant reaction tube, and then 3 mL of acetonitrile was added as a solvent. Then, it was magnetically stirred at 0°C for 36 hours. After cooling to room temperature, 10 mL of water was added, and extracted with dichloromethane (3*10 mL), the organic phases were combined and washed with anhydrous Na 2 SO 4 Dry, and then filter the filtrate to remove the solvent, then separate it by silica gel column chromatography, use petroleum ether / ethyl acetate = 30:1 as the eluent, collect the eluate containing the target product and evaporate the solvent to obtain benzoisocoumarin white. The material was a white solid in 80% yield.

[0043] Characterization data: IR(KBr,cm -1 ):ν=1733,1602; 1 H NMR (500MHz, CDCl 3 ):δ8.43(dd,J 1 =7.5Hz,J 2 =1.0Hz,1H),8.15(d,J=8.5Hz,1H),8.09(dd,J 1 =8....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com