Lubricating coating for surface of medical instrument and application of lubrication coating

A technology of medical devices and coatings, which is applied in the field of medical devices, can solve problems such as poor firmness, and achieve the effects of lubricity, practicability and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

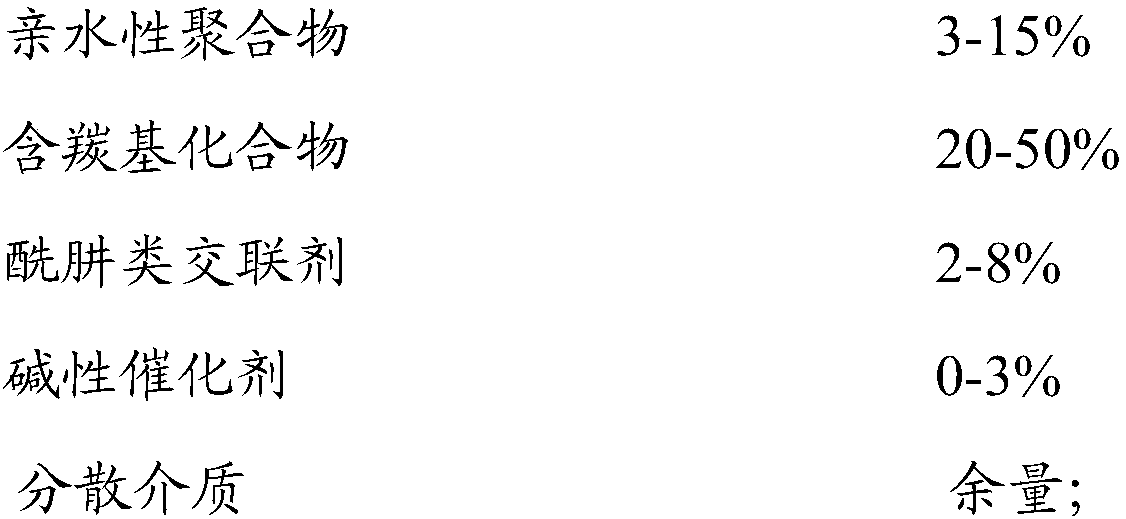

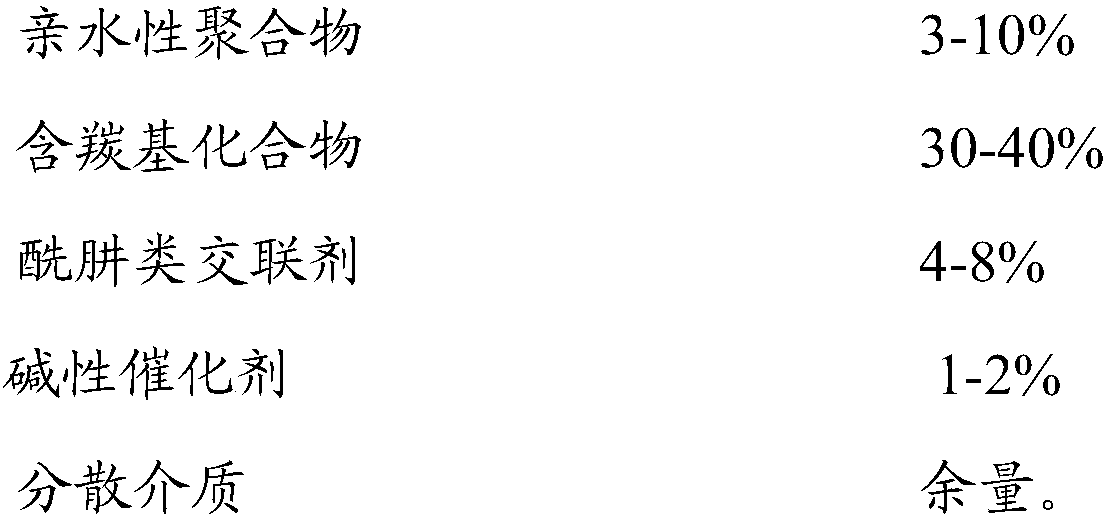

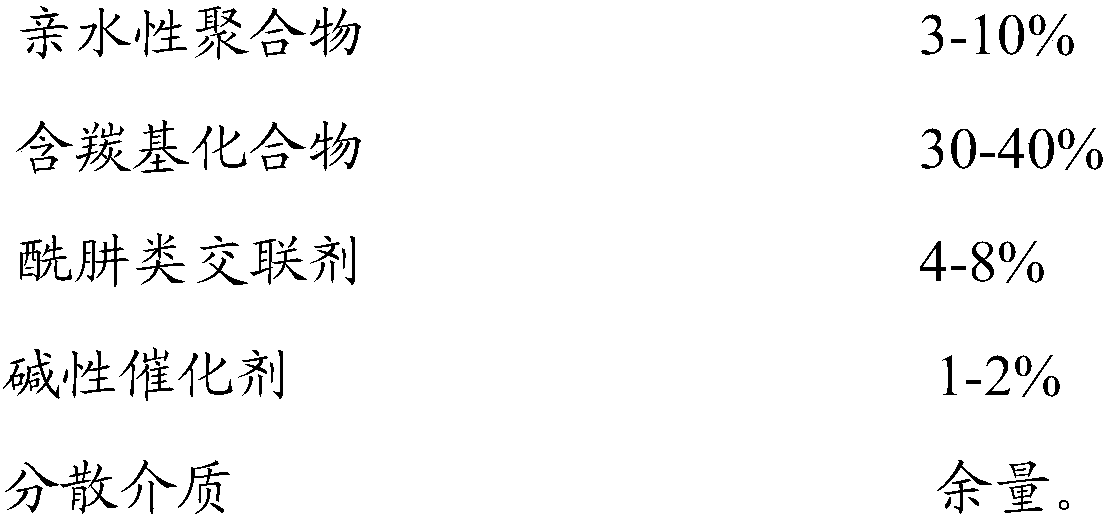

[0054] Embodiment 1 Lubricating coating formula for medical device surface

[0055] The lubricating coating for the surface of the medical device comprises a hydrophilic polymer, a carbonyl-containing compound, a hydrazide cross-linking agent and a dispersion medium. Eighteen paint formulations are given in Table 1.

[0056] Table 1 Coating Formulation

[0057]

[0058]

[0059] The components of the paint are stored separately, and are temporarily configured for spraying when used, and the storage period is 24 hours.

Embodiment 2

[0064] The preparation of the hydrophilic coating on the surface of embodiment 2 medical device

[0065] Put polyvinylpyrrolidone and N-vinylpyrrolidone-acrylic acid copolymer in the container according to the ratio of formula 1; then add ethanol into the container; then add dihydrazide carbonate and triethylamine into the container, wait for the container to After a homogeneous mixture had formed, the solution formulation was complete. Spray the prepared solution onto the surface of the medical device, heat and cure it in an oven, the curing temperature is 60-130°C, and form a hydrophilic coating on the surface of the medical device with a lubricating coating on the surface of the medical device. 10-30μm.

Embodiment 3

[0066] Embodiment 3 lubricity and firmness test experiment

[0067] The method of Example 2 was used to coat part of the paint formulation in Example 1 on the catheter substrate, and the friction force outside the catheter was tested 20 times to investigate the firmness and durability of the coating. The lower the friction, the better the lubricity; after 20 times of friction, the lower the friction, the smaller the change, indicating that the coating is less abrasive, that is, the coating has better firmness. Samples were prepared after coating or not coating the coating formulations involved in the present invention on different catheter substrates, and a positive pressure of 300gf was applied to the samples, and the friction force was tested in a water bath environment at 37°C. The experimental results are given in Table 2.

[0068] Table 2 The friction results of different materials after 20 times

[0069]

[0070]

[0071] " / *" in Table 2 indicates that the fricti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com