Method of producing thin hot-formed steel based on CSP (chip scale package) process

A hot-formed steel, thin-gauge technology, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of warping, folding, tailing, poor plastic deformation ability of steel, and elongation of thin hot-formed steel It can improve the quality of the plate shape, reduce the production cost and improve the surface quality of the product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

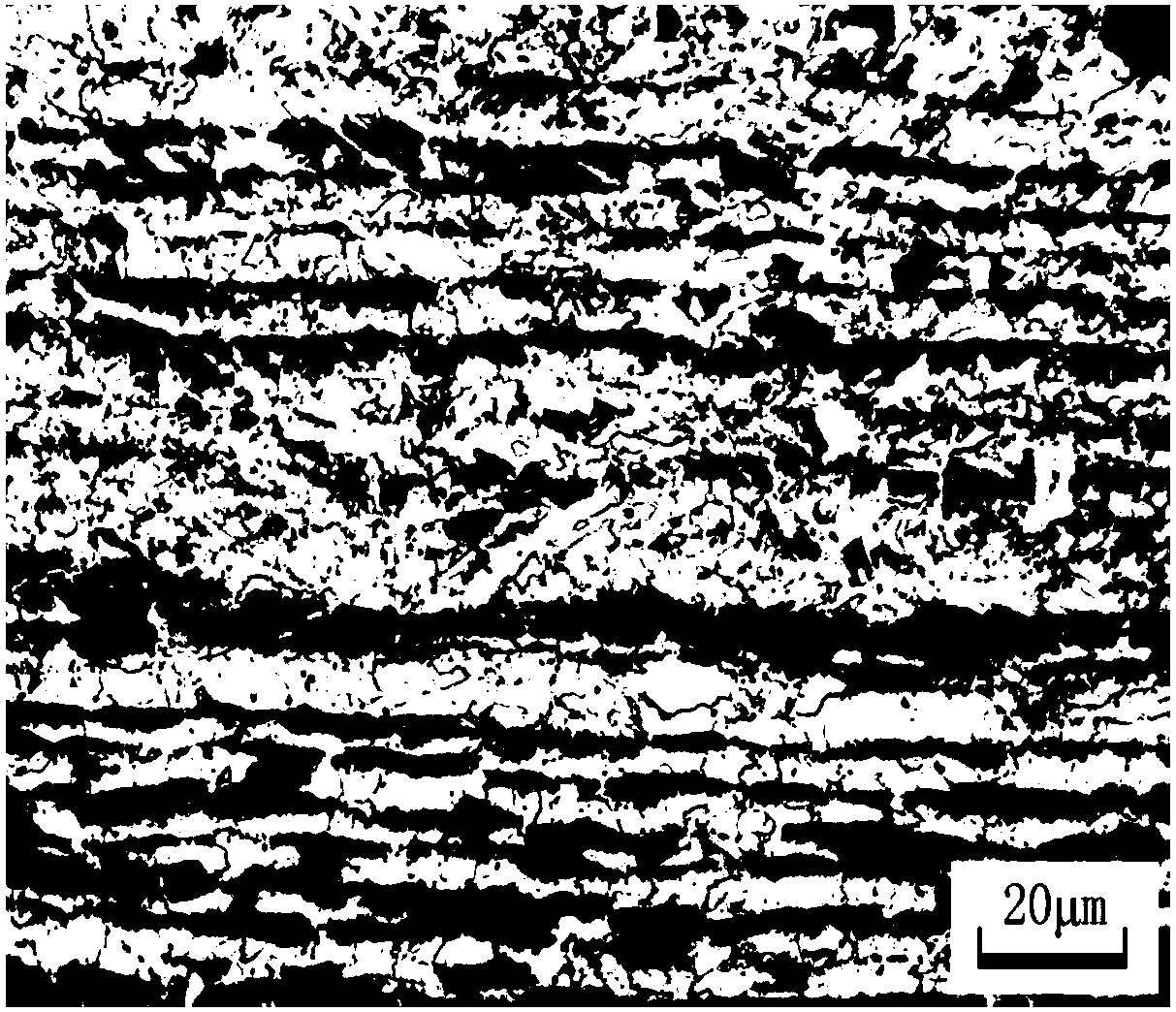

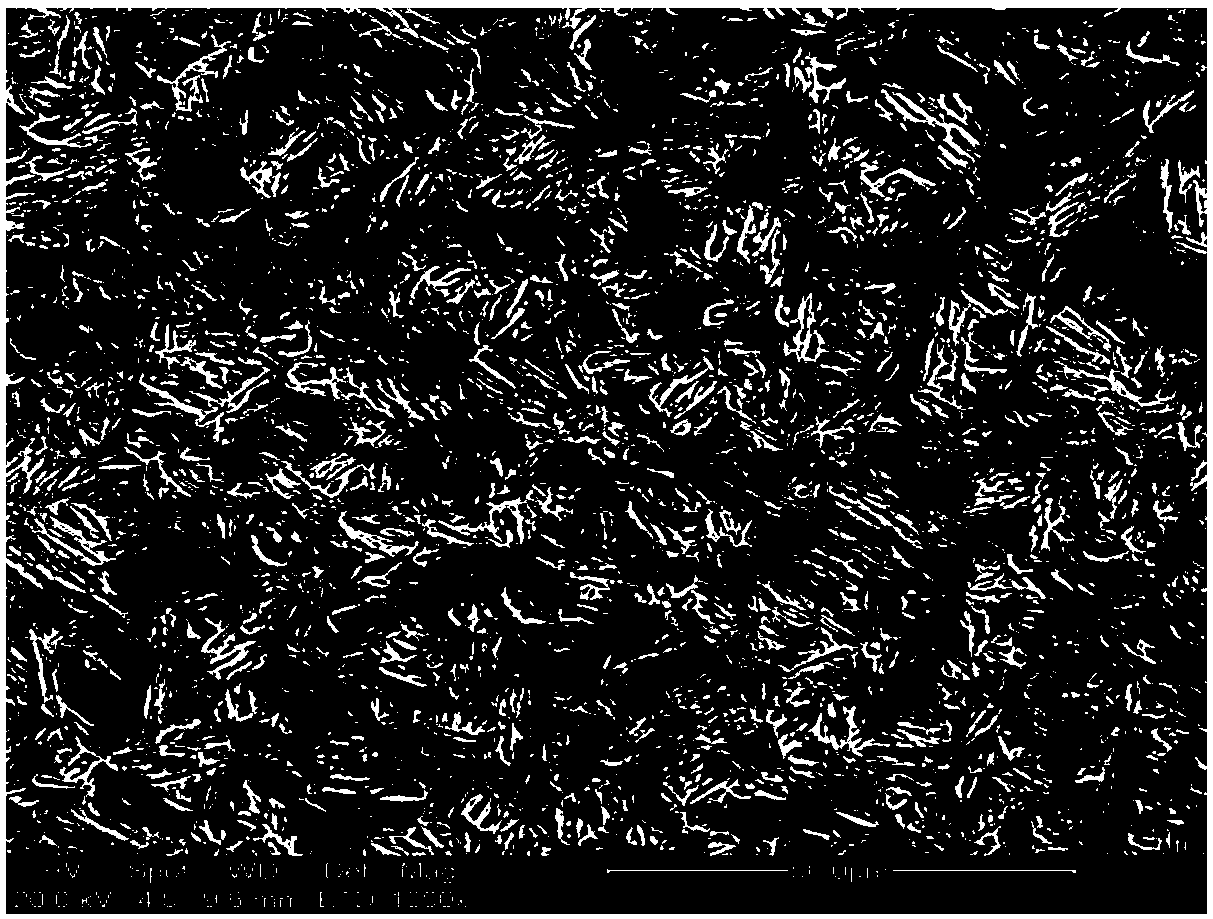

Image

Examples

Embodiment 1~6

[0032] The thin gauge hot formed steel in the following embodiments is manufactured as follows:

[0033] 1) Steelmaking: converter smelting and refining outside the furnace to obtain refined molten steel;

[0034] 2) Continuous casting: The refined molten steel is cast into a billet on the continuous casting machine on the CSP thin slab continuous casting and rolling production line. The thickness of the cast billet is controlled to 70mm in the pouring stage, and it is reduced to 52-60mm by the liquid core, and then drawn Speed control at 3.5~4.0m / min;

[0035] 3) Soaking: the slab is soaked in a soaking furnace, the temperature of the cast slab is controlled to be 1200-1220℃, and the soaking time is 25 to 35min;

[0036] 4) Descale: High pressure descale on the soaked billet;

[0037] 5) Finishing rolling: the cast billet enters the finishing mill, the cooling water of the roll gap of the F1~F4 stand is controlled to be turned on before the strip head reaches the stand, and the stri...

Embodiment 6

[0054] The measured dimensional tolerances of the B-pillar parts obtained after stamping and forming of the thin gauge hot-formed steel obtained in Example 6 are shown in Table 6;

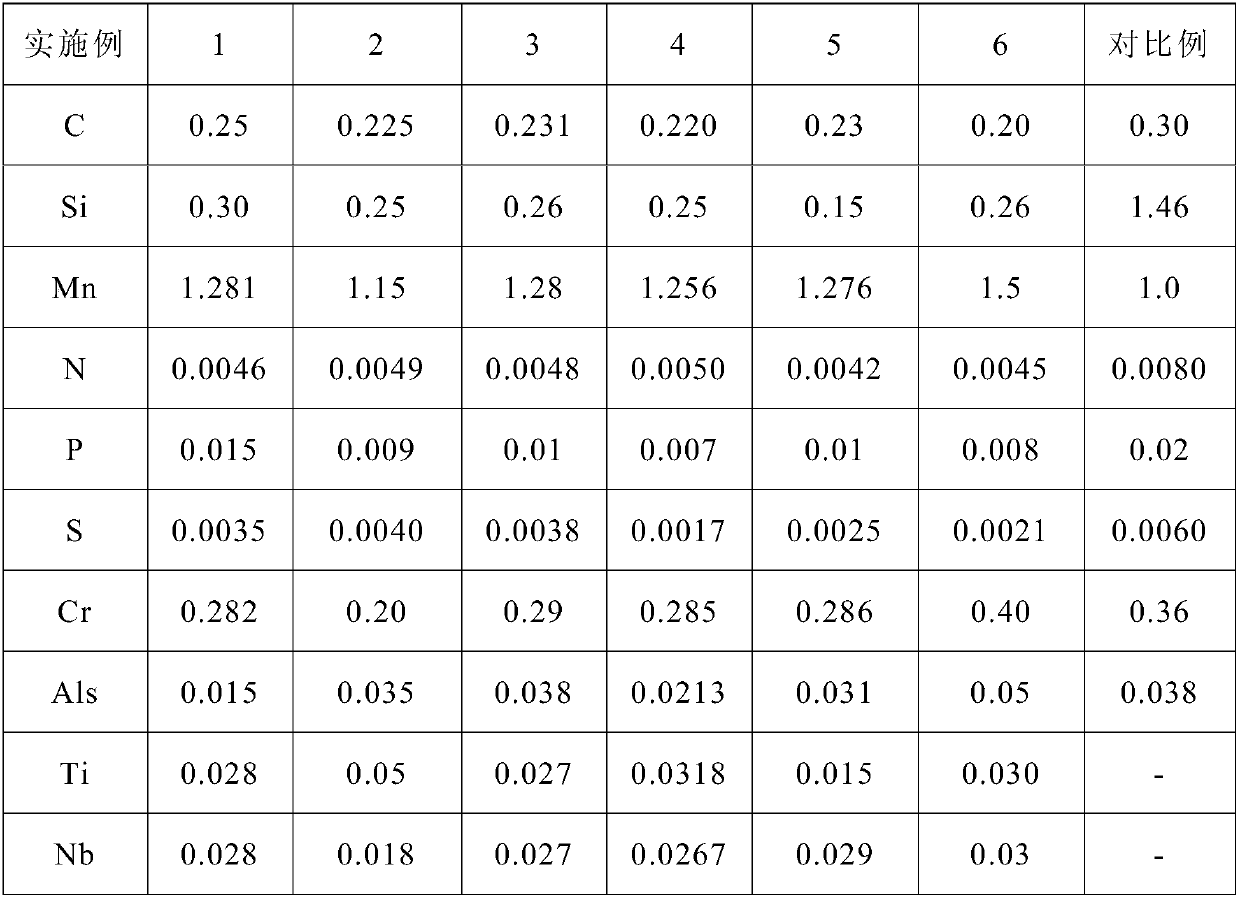

[0055] Table 1 The chemical composition and weight percentage of hot formed steel in Examples 1 to 6 and Comparative Examples

[0056]

[0057]

[0058] Table 2 Specific process parameters of Examples 1 to 6

[0059] index

[0060] Table 3 Process control and surface quality of Examples 1 to 6 and Comparative Examples

[0061]

[0062]

[0063] It can be seen from Table 3 that compared with the prior art (comparative example), the thin-gauge hot-formed steel obtained in Examples 1 to 6 of the present invention has higher flatness, thickness, and wedge accuracy, and the production process is stable without occurrence Head-lifting, folding, tail-flicking and other accidents, the product surface quality is excellent; the head folding accident occurred in the production process of the comparative example, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com