Method for preparing onion carbon/MXene layered wave absorbing composite material

A composite material, onion carbon technology, applied in magnetic field/electric field shielding, electrical components, antennas, etc., to achieve the effects of light weight, good reflectivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

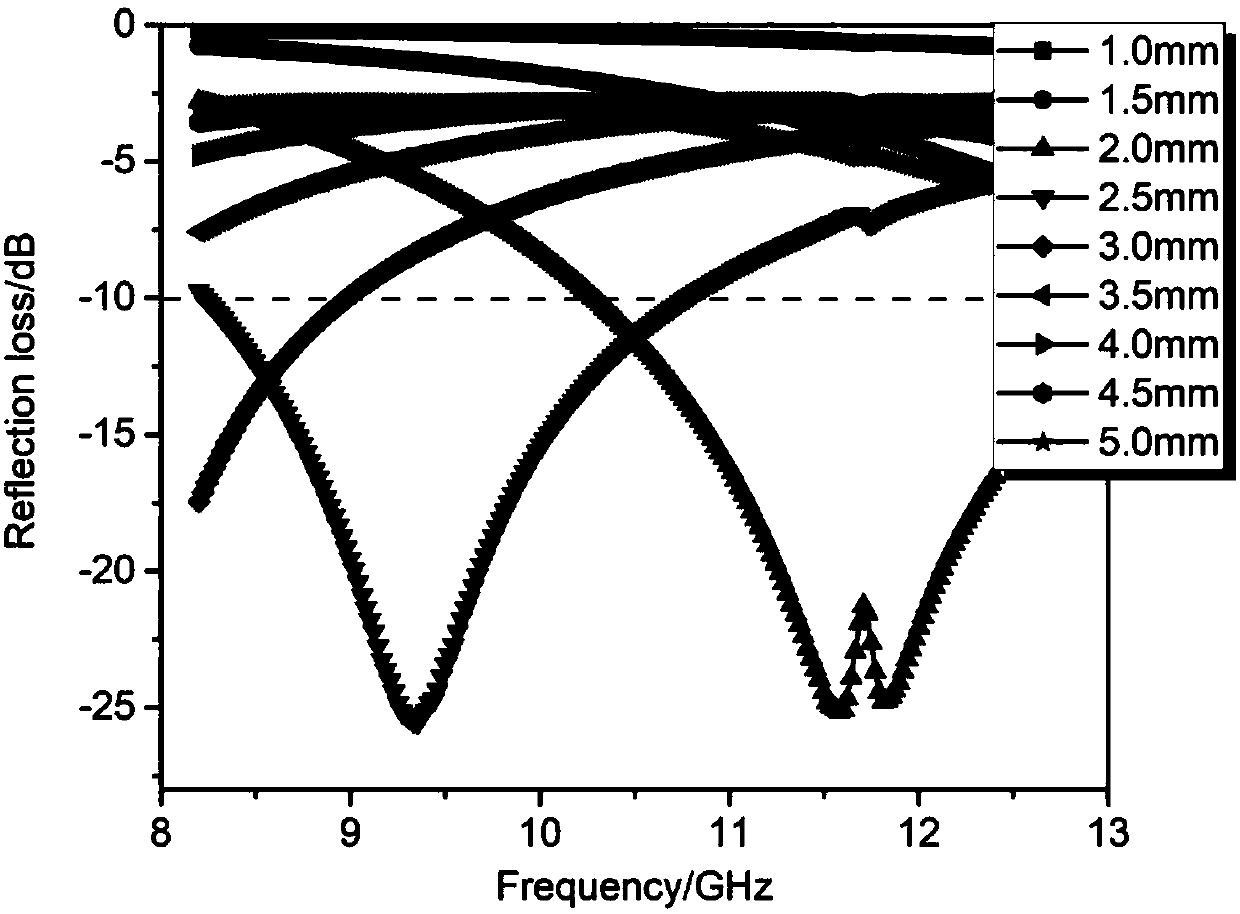

Image

Examples

Embodiment 1

[0030] In step 1, the titanium silicon carbon material is used as a raw material, soaked in a hydrofluoric acid solution with a concentration of 40%, and the soaking time is 48 hours, and then washed 5 times with deionized water, and dried in an oven at 120 degrees to obtain MXene material;

[0031] In step 2, the MXene material dried in step 1 is uniformly dispersed in a deionized aqueous solution with a concentration of 40% by ultrasonic method;

[0032] Step 3, uniformly dispersing the onion carbon nanomaterial in the deionized aqueous solution by ultrasonic method, the concentration is 40%;

[0033] Step 4, using the MXene material suspension solution prepared in step 2 and step 3 and preparing the onion carbon nanomaterial suspension solution as raw materials, wherein, the MXene material suspension solution consumption is 100 milliliters, and the onion carbon nanomaterial suspension solution consumption is 100 ml, the onion carbon / MXene layered microwave-absorbing compos...

Embodiment 2

[0035] Step 1, the titanium silicon carbon material is used as a raw material, soaked in a hydrofluoric acid solution with a concentration of 20%, and the soaking time is 36 hours, and then washed with deionized water for 4 times, and dried in an oven at 100 degrees to obtain MXene material;

[0036] In step 2, the MXene material dried in step 1 is uniformly dispersed in deionized aqueous solution with a concentration of 20% by ultrasonic method;

[0037] Step 3, uniformly dispersing the onion carbon nanomaterial in the deionized aqueous solution by ultrasonic method, the concentration is 20%;

[0038] Step 4, using the MXene material suspension solution prepared in step 2 and step 3 and preparing the onion carbon nanomaterial suspension solution as raw materials, wherein, the MXene material suspension solution consumption is 300 milliliters, and the onion carbon nanomaterial suspension solution consumption is 300 ml, the onion carbon / MXene layered wave-absorbing composite ma...

Embodiment 3

[0040] Step 1, the titanium silicon carbon material is used as a raw material, soaked in a hydrofluoric acid solution with a concentration of 40%, the soaking time is 24 hours, and then washed with deionized water for 3 times, and dried in an oven at 80 degrees to obtain MXene material;

[0041] In step 2, the MXene material dried in step 1 is uniformly dispersed in a deionized aqueous solution with a concentration of 30% by ultrasonic method;

[0042] Step 3, uniformly dispersing the onion carbon nanomaterial in the deionized aqueous solution by ultrasonic method, the concentration is 30%;

[0043] Step 4, using the MXene material suspension solution prepared in step 2 and step 3 and preparing the onion carbon nanomaterial suspension solution as raw materials, wherein, the MXene material suspension solution consumption is 500 milliliters, and the onion carbon nanomaterial suspension solution consumption is 500 ml, the onion carbon / MXene layered microwave-absorbing composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com