Machining method for wind-power ground anchor bolt

A processing method and bolt technology, applied to bolts, nuts, threaded fasteners, etc., can solve the problems of cost increase, wind power ground anchor bolt cost increase, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

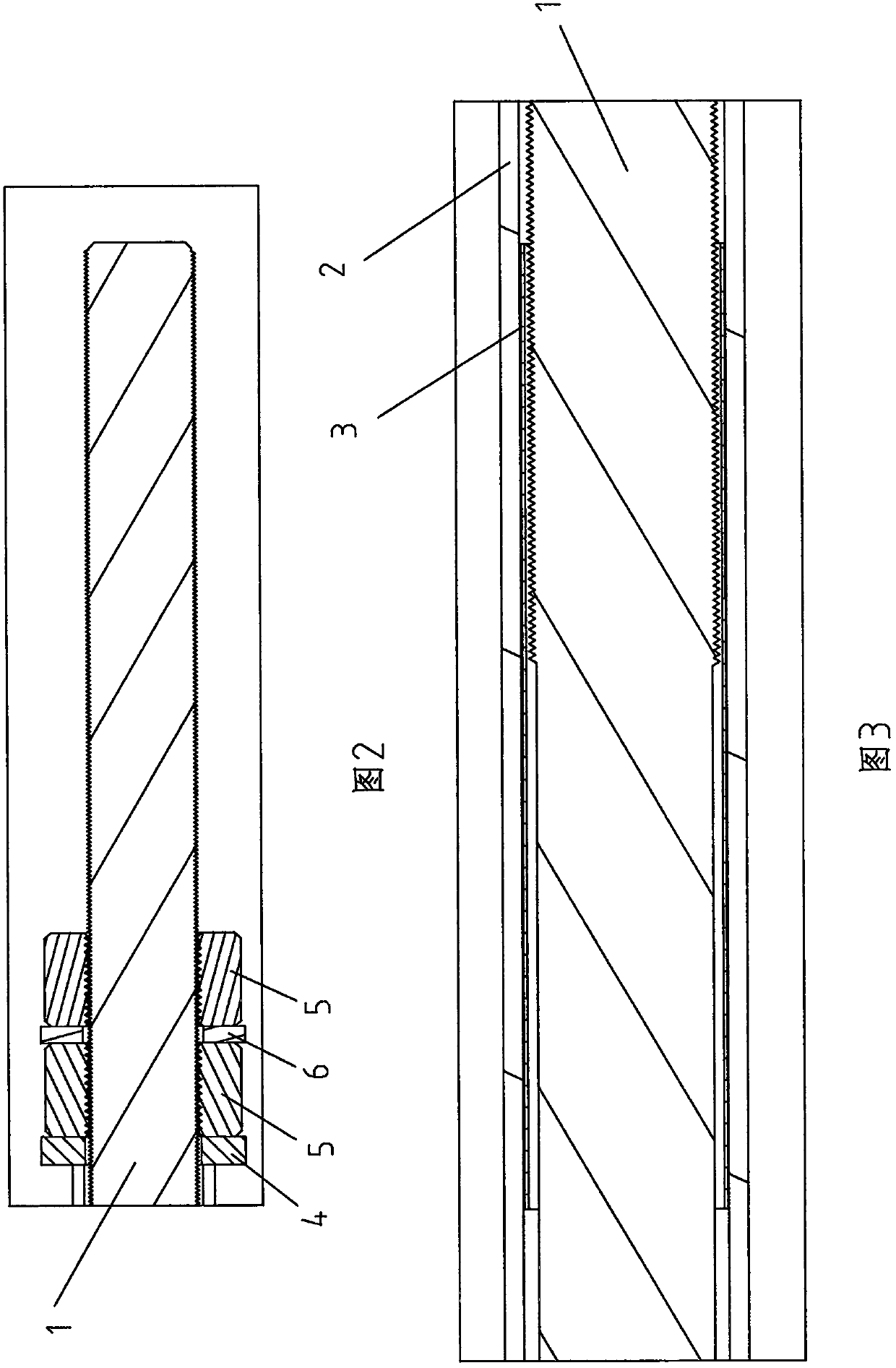

[0018] The specific embodiments of the present invention are given in conjunction with the accompanying drawings. The detailed description of the specific embodiments that needs to be explained is to facilitate the understanding of the technical essence of the present invention, and should not be regarded as limiting the protection scope of the claims of the present invention.

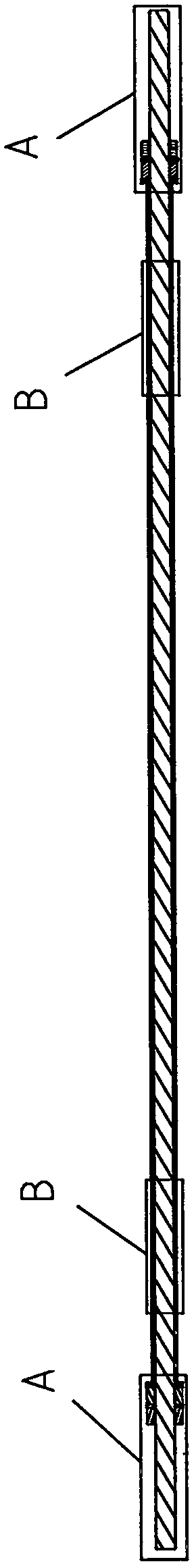

[0019] See Figure 1 ~ Figure 3 , the technical scheme of the specific embodiment of the present invention is: a. carry out the heat treatment quenching and tempering according to the technical requirements to the alloy steel bar; Anti-corrosion treatment is carried out on the threaded alloy steel bar; d. Assemble the corresponding nuts and washers as required to obtain the required wind power ground anchor bolt 1 .

[0020] In the above-mentioned preparation method, step a is to heat-treat and temper the alloy steel bar, so that the yield ratio, toughness and plasticity of the bar are significantly im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com