Alkali-activated high-titanium content slag small-sized hollow block and preparation method thereof

A technology of high-titanium slag and hollow blocks, which is applied in the field of alkali-activated high-titanium slag small-sized hollow blocks and its preparation, can solve the problems of heavy weight, difficult transportation and construction, and high density of a single block, so as to reduce production energy consumption and The effect of resource consumption, easy transportation and construction, low bulk density and apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

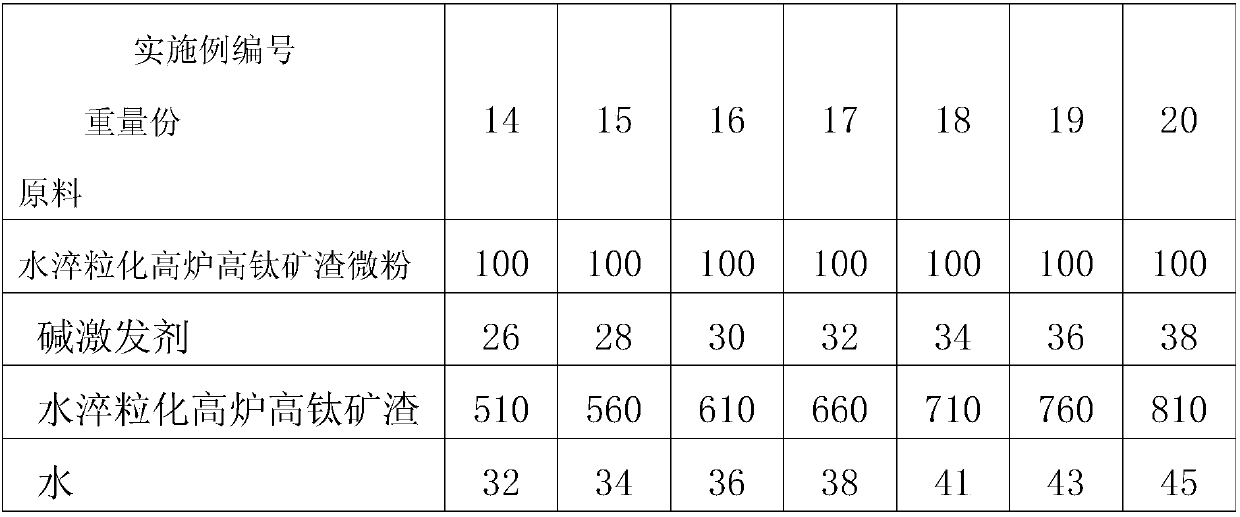

Examples

Embodiment 1

[0031] A small hollow block of alkali-activated high-titanium slag, which is composed of: 100 parts by weight of water-quenched blast furnace high-titanium slag fine powder, 35 parts by weight of alkali activator, and 468 parts by weight of water-quenched granulated blast furnace high-titanium Slag and 35 parts by weight of water are mixed.

[0032]The preparation method of alkali-activated high-titanium slag permeable products is as follows:

[0033] 1) According to the ratio of 100 parts by weight of water-quenched and granulated high-titanium slag fine powder, 35 parts by weight of alkali activator, 468 parts by weight of water-quenched and granulated high-titanium slag, and 35 parts by weight of water, the raw materials of each component are obtained;

[0034] 2) mixing and stirring water-quenched and granulated blast furnace high-titanium slag fine powder, alkali activator, water-quenched and granulated blast-furnace high-titanium slag and water to prepare a wet mixture; ...

Embodiment 2

[0038] A small hollow block of alkali-activated high-titanium slag, which consists of: 100 parts by weight of water-quenched blast furnace high-titanium slag fine powder, 35 parts by weight of alkali activator, and 585 parts by weight of water-quenched granulated blast furnace high-titanium Slag and 35 parts by weight of water are mixed.

[0039] The preparation method of alkali-activated high-titanium slag permeable products is as follows:

[0040] 1) According to the ratio of 100 parts by weight of water-quenched and granulated high-titanium slag fine powder, 35 parts by weight of alkali activator, 585 parts by weight of water-quenched and granulated high-titanium slag, and 35 parts by weight of water, the raw materials of each component are taken;

[0041] 2) mixing and stirring water-quenched and granulated blast furnace high-titanium slag fine powder, alkali activator, water-quenched and granulated blast-furnace high-titanium slag and water to prepare a wet mixture;

[0...

Embodiment 3

[0045] A small hollow block of alkali-activated high-titanium slag, which consists of: 100 parts by weight of water-quenched blast furnace high-titanium slag fine powder, 35 parts by weight of alkali activator, and 702 parts by weight of water-quenched granulated blast furnace high-titanium Slag and 35 parts by weight of water are mixed.

[0046] The preparation method of alkali-activated high-titanium slag permeable products is as follows:

[0047] 1) According to the ratio of 100 parts by weight of water-quenched and granulated high-titanium slag fine powder, 35 parts by weight of alkali activator, 702 parts by weight of water-quenched and granulated high-titanium slag, and 35 parts by weight of water, the raw materials of each component are obtained;

[0048] 2) mixing and stirring water-quenched and granulated blast furnace high-titanium slag fine powder, alkali activator, water-quenched and granulated blast-furnace high-titanium slag and water to prepare a wet mixture;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com