Preparation method of carbon nano-tube graphene inorganic zinc-enriched anti-corrosion coating

A carbon nanotube, inorganic zinc-rich technology, used in anti-corrosion coatings, conductive coatings, coatings, etc., can solve problems such as endangering the life and health of workers and differences in the passivation of steel substrates, reducing zinc oxide fog, time-consuming Short, the effect of reducing the content of zinc powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

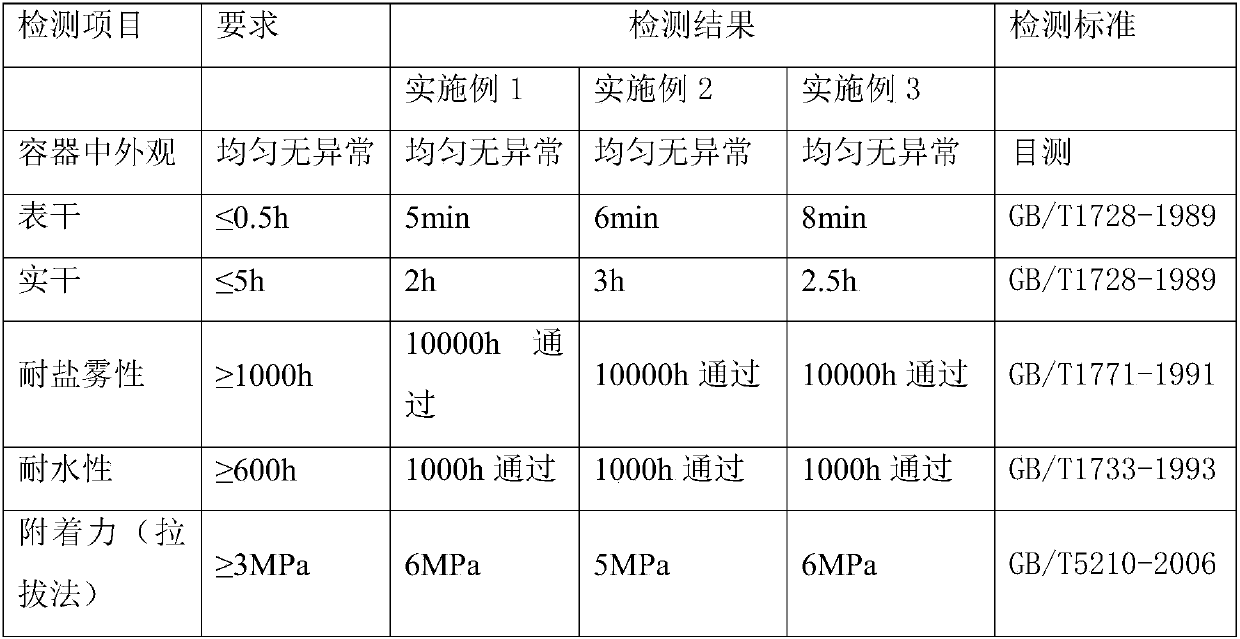

Examples

Embodiment Construction

[0025] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0026] The present invention will be described in detail below in conjunction with examples.

[0027] 1, a kind of preparation method of carbon nanotube graphene inorganic zinc-rich anticorrosion coating, comprises the steps:

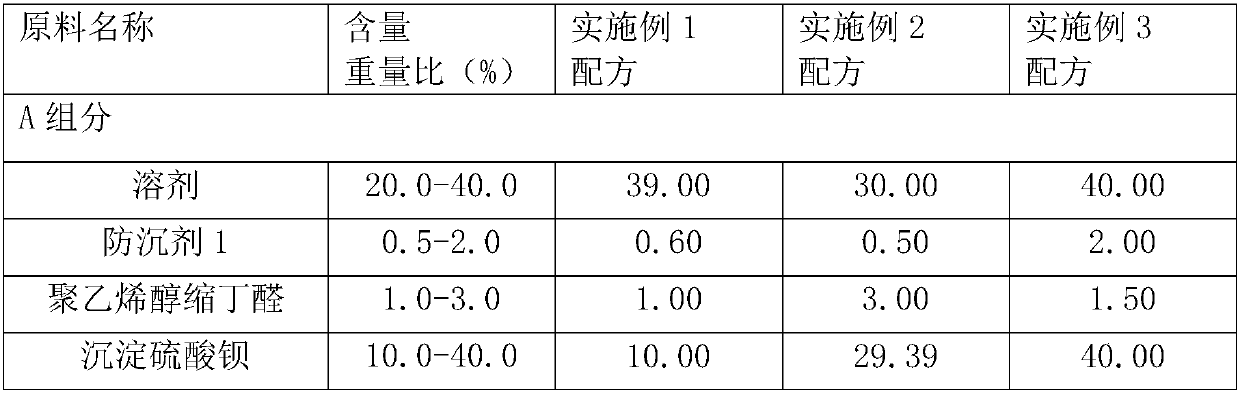

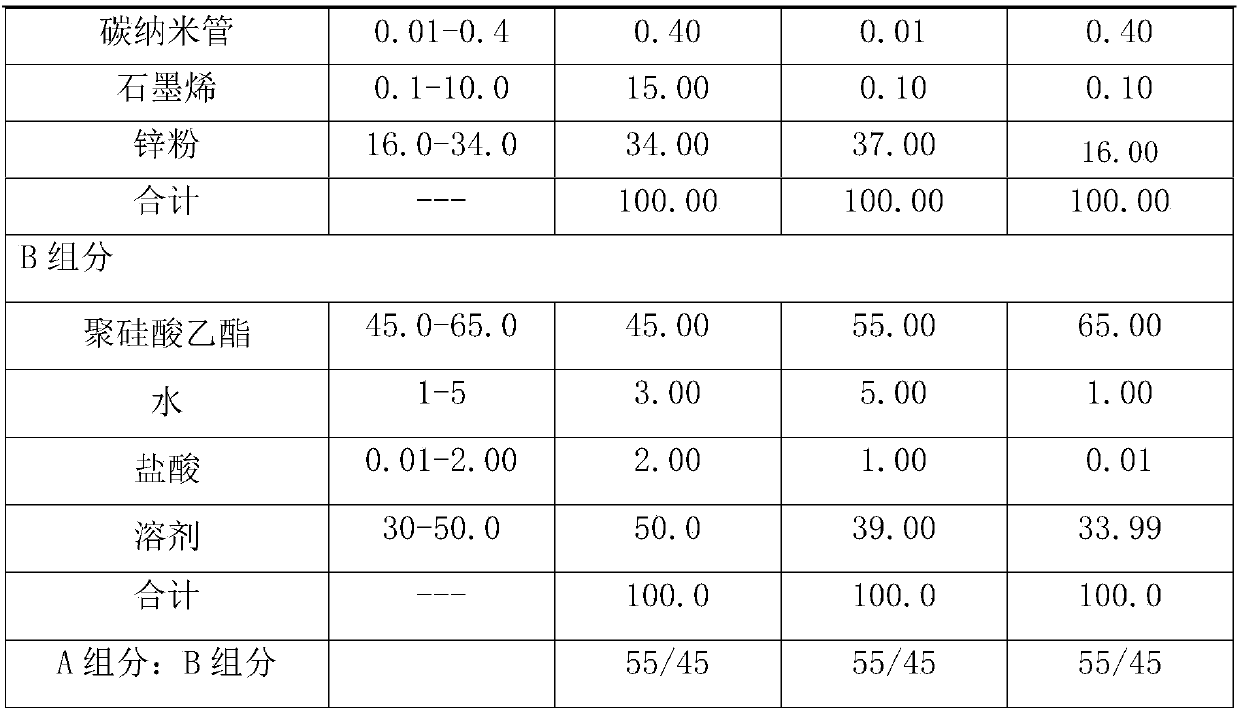

[0028] (1) Preparation of component A: add solvent, slowly add anti-settling agent under stirring condition, add polyvinyl butyral after high-speed dispersion, the dispersion speed of the disperser is 600r / min, and the dispersion time is 30min. After the carbon nanotubes are uniformly dispersed, they are ground with grinding sand, the grinding temperature is 50...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap