Antibacterial environment-friendly film and preparation method thereof

An antibacterial and environmental protection film and an antibacterial layer technology are applied in the field of antibacterial and environmental protection films and their preparation, which can solve the problems of easy water absorption and deterioration, easy to stain dust, poor environmental protection performance, etc., and achieve good sterilization and antivirus effect, no pollution to the environment, and good durability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of antibacterial environmental protection film, described antibacterial environmental protection film is PET layer, antibacterial layer, PE layer, bactericidal coating successively from inside and outside, wherein, the thickness of PET layer and PE layer is 25 μ m, the difference between bactericidal coating and antibacterial layer The thicknesses are all 50 μm.

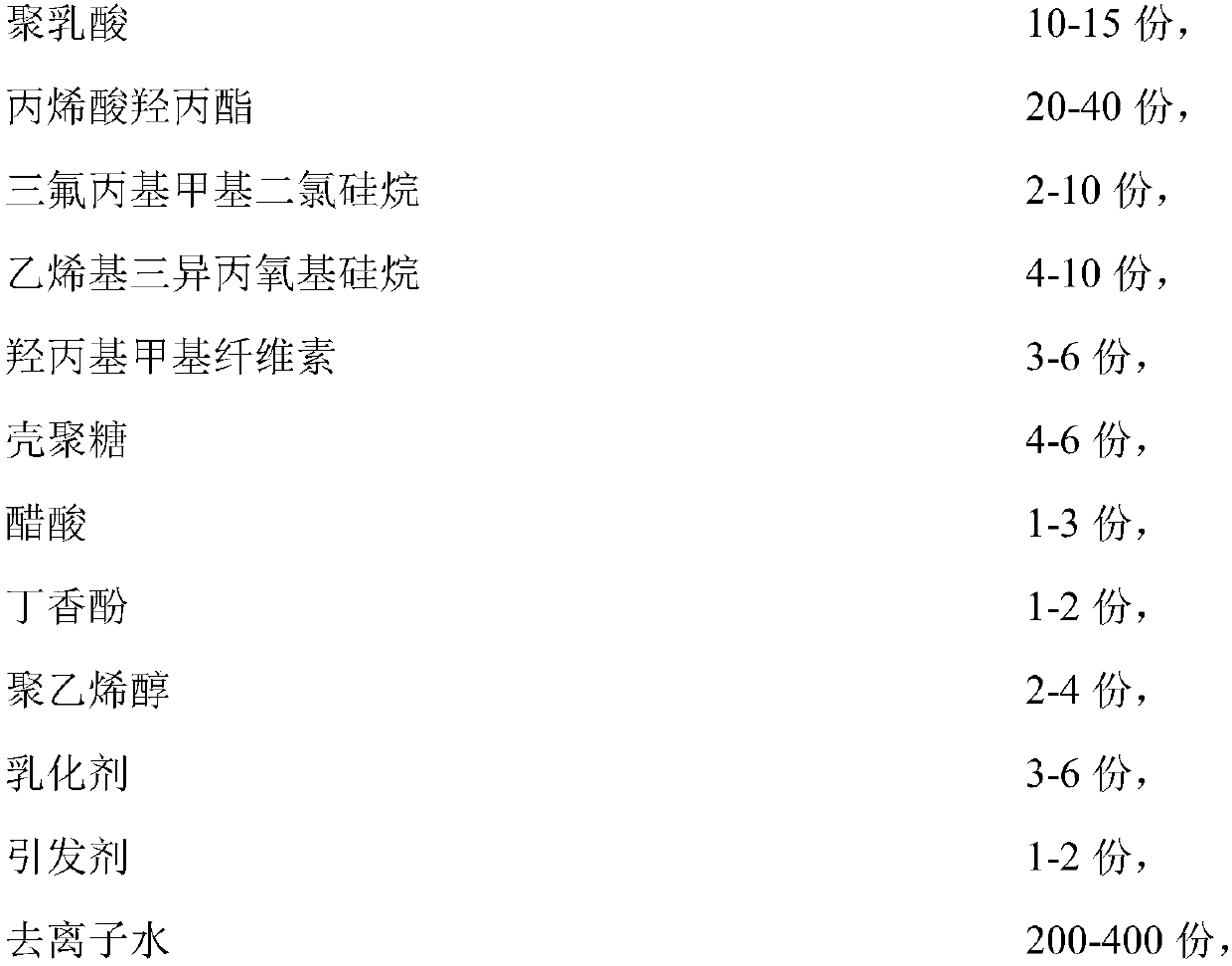

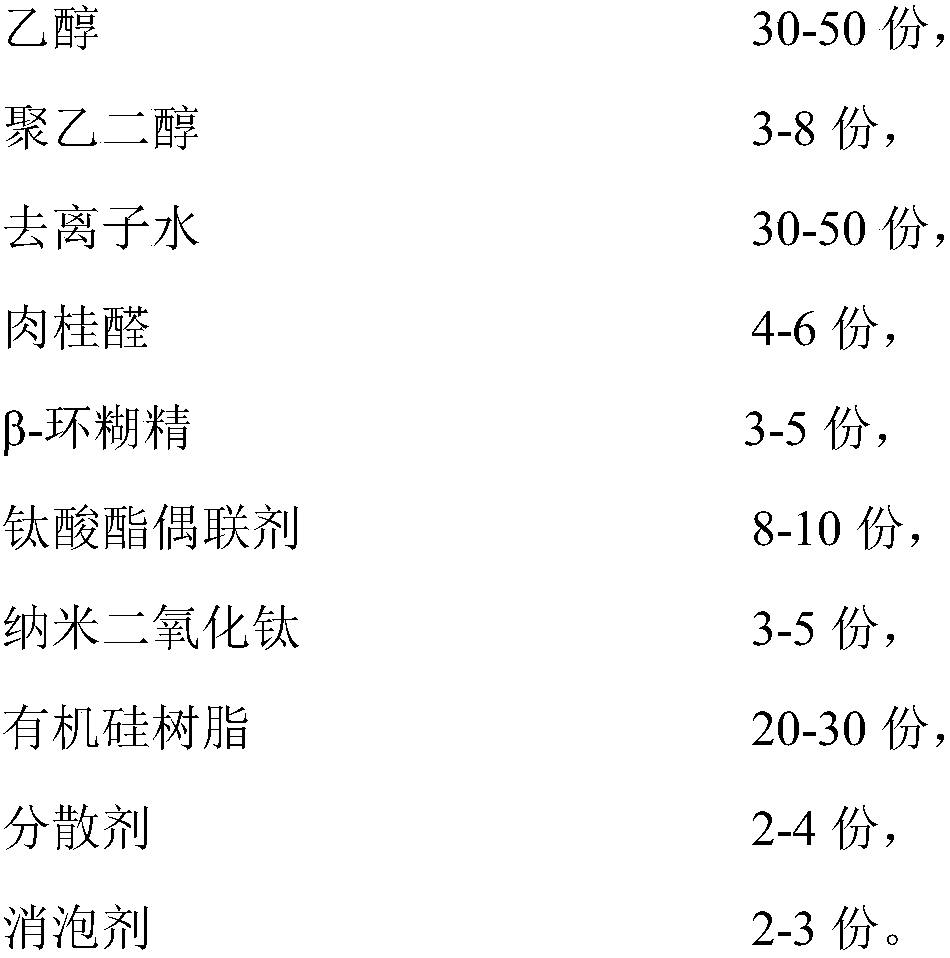

[0036] The coating that described antibacterial layer is used is to be formulated by the raw material of following weight part:

[0037]

[0038]

[0039] The used coating of described antibacterial agent layer is prepared by the following method:

[0040] (1) Preparation of pre-emulsion

[0041] Polylactic acid, hydroxypropyl acrylate, emulsifier, initiator, trifluoropropylmethyldichlorosilane, vinyl triisopropoxysilane, polyvinyl alcohol and 1 / 2 weight part of deionized mixed with water, pre-emulsified to obtain a pre-emulsion;

[0042] (2) Emulsion polymerization

[0043] The hydroxypropyl ...

Embodiment 2

[0050] An antibacterial environmental protection film, the antibacterial environmental protection film is a PET layer, an antibacterial layer, a PE layer, and a bactericidal coating in sequence from the inside to the outside, wherein the thickness of the PET layer is 22 μm, the thickness of the antibacterial layer is 50 μm, and the thickness of the PE layer is 25 μm , The thickness of the bactericidal coating is 53μm.

[0051] The coating that described antibacterial layer is used is to be formulated by the raw material of following weight portion:

[0052]

[0053] The used coating of described antibacterial agent layer is prepared by the following method:

[0054] (1) Preparation of pre-emulsion

[0055] Polylactic acid, hydroxypropyl acrylate, emulsifier, initiator, trifluoropropylmethyldichlorosilane, vinyl triisopropoxysilane, polyvinyl alcohol and 3 / 4 weight part of deionized mixed with water, pre-emulsified to obtain a pre-emulsion;

[0056] (2) Emulsion polymeriz...

Embodiment 3

[0065] An antibacterial environmental protection film, the antibacterial environmental protection film is a PET layer, an antibacterial layer, a PE layer, and a bactericidal coating in sequence from the inside to the outside, wherein the thickness of the PET layer is 30 μm, the thickness of the antibacterial layer is 55 μm, and the thickness of the PE layer is 24 μm , The thickness of the bactericidal coating is 60μm. .

[0066] The coating that described antibacterial layer is used is to be formulated by the raw material of following weight portion:

[0067]

[0068]

[0069] The used coating of described antibacterial agent layer is prepared by the following method:

[0070] (1) Preparation of pre-emulsion

[0071] Polylactic acid, hydroxypropyl acrylate, emulsifier, initiator, trifluoropropylmethyldichlorosilane, vinyl triisopropoxysilane, polyvinyl alcohol and 3 / 5 parts by weight of deionized mixed with water, pre-emulsified to obtain a pre-emulsion;

[0072] (2)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com