Nano-metallic material, preparation method of nano-metallic material and micro-jet equipment

A metal material and nano-metal technology, applied in the field of nano-materials, can solve the problems of the valve core not being resistant to wear, easy to be damaged, and easy to block the needle-shaped injection port, so as to achieve the effect of solving easy blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

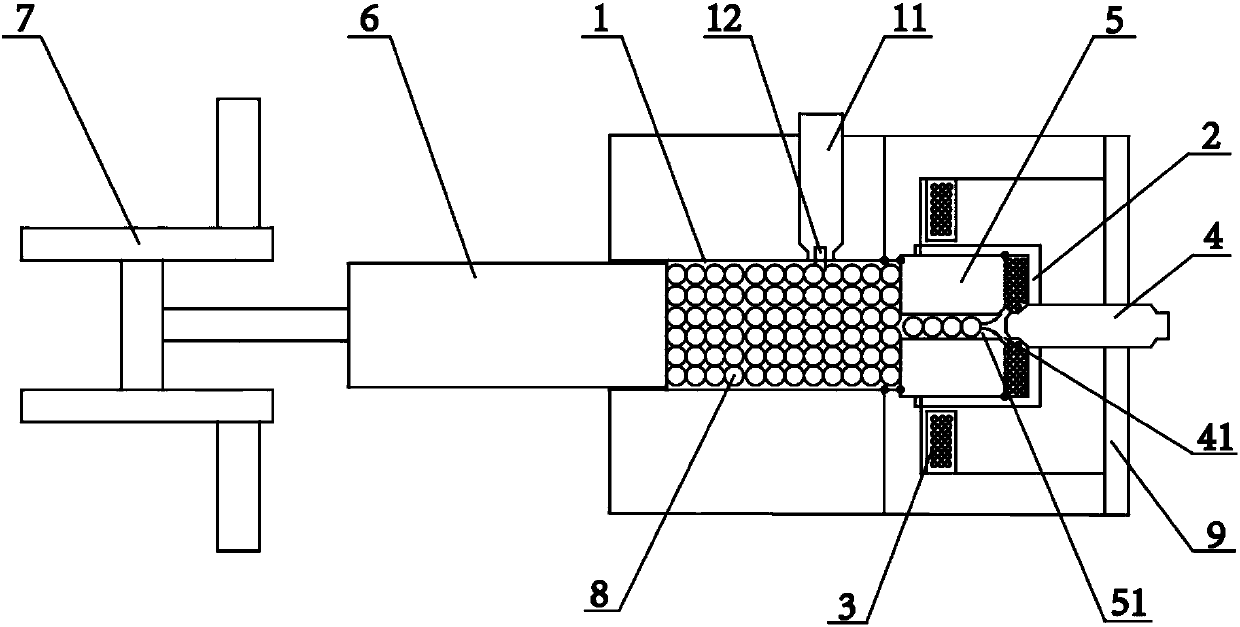

[0056] According to another aspect of the present invention, there is also provided a method for preparing a nano-metal material, using the above-mentioned micro-fluidic device comprising the following steps:

[0057] (1) Mix the metal material, dispersant, thickener and optional metal complexing agent, and stir to obtain a metal dispersion;

[0058] (2) Move the metal dispersion to the feeding chamber of the micro-fluidic equipment. Under the action of the piston, the metal dispersion in the feeding chamber passes through the slit channel on the valve seat and the gap between the valve core and the valve seat. The annular gap enters the reaction chamber, and after several times of micro-jet circulation, a nano-metal solution is obtained;

[0059] (3) centrifuging the nano-metal solution and drying the nano-metal precipitate to obtain a nano-metal material.

[0060] The invention provides a method for preparing a nanometer metal material. The preparation method has simple pro...

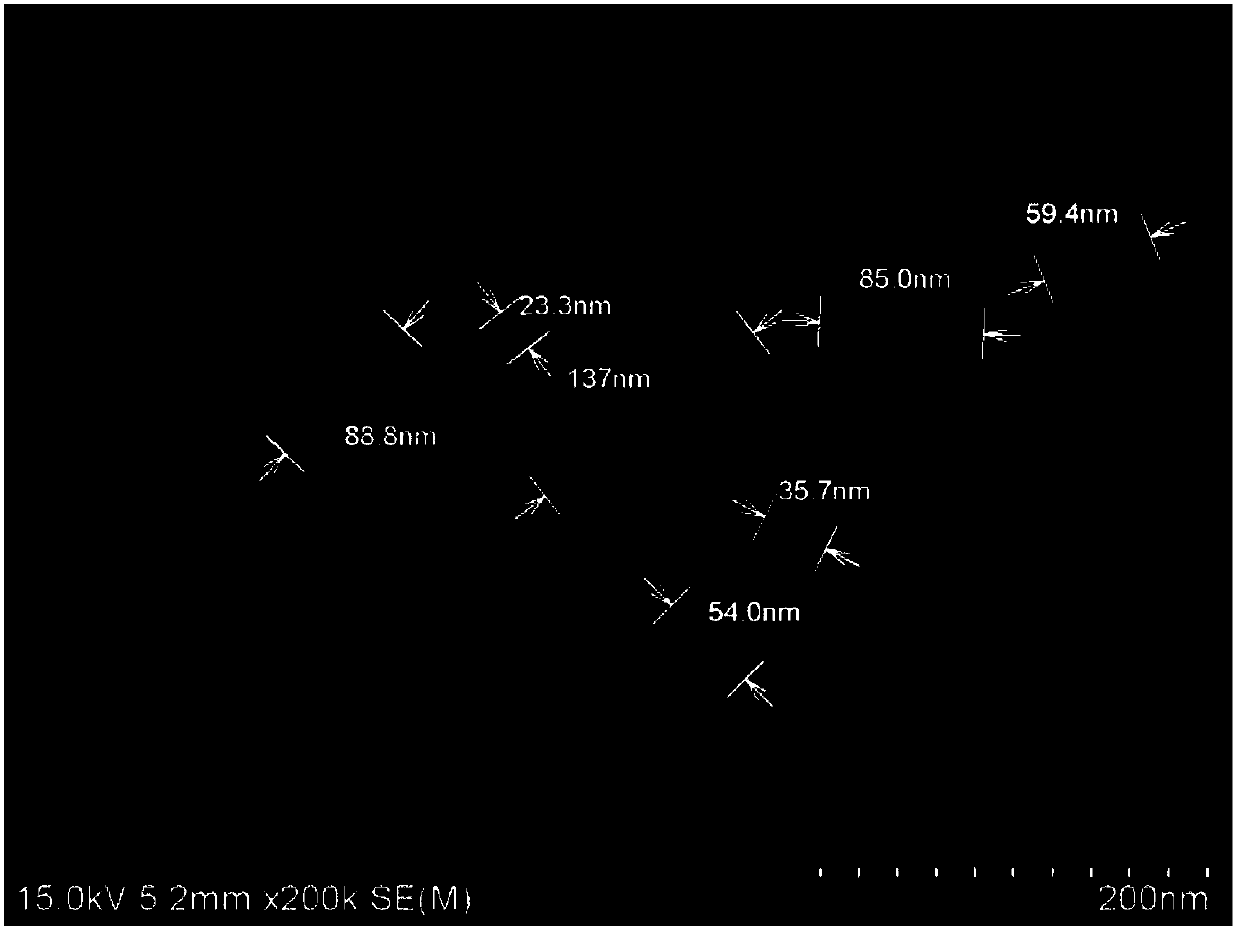

Embodiment 1

[0088] A preparation method of nano silver powder, comprising the steps of:

[0089] (1) Mix silver powder, ethanol, water, polyethylene glycol and sodium polyacrylate at 60°C, and stir to obtain a metal dispersion;

[0090] Wherein, according to weight fraction, silver powder accounts for 1% by weight of raw materials, polyethylene glycol accounts for 1% by weight of raw materials, sodium polyacrylate accounts for 0.3% by weight of raw materials, and ethanol accounts for 1% by weight of raw materials. %, water to make up the balance to 100%.

[0091] (2) Move the metal dispersion to a micro-fluidic device, and process it once in a 200MPa micro-fluidic cycle to obtain a nano-metal solution.

[0092] (3) Precipitate the nano-silver obtained after the nano-metal solution is centrifuged, and dry to obtain a nano-silver powder.

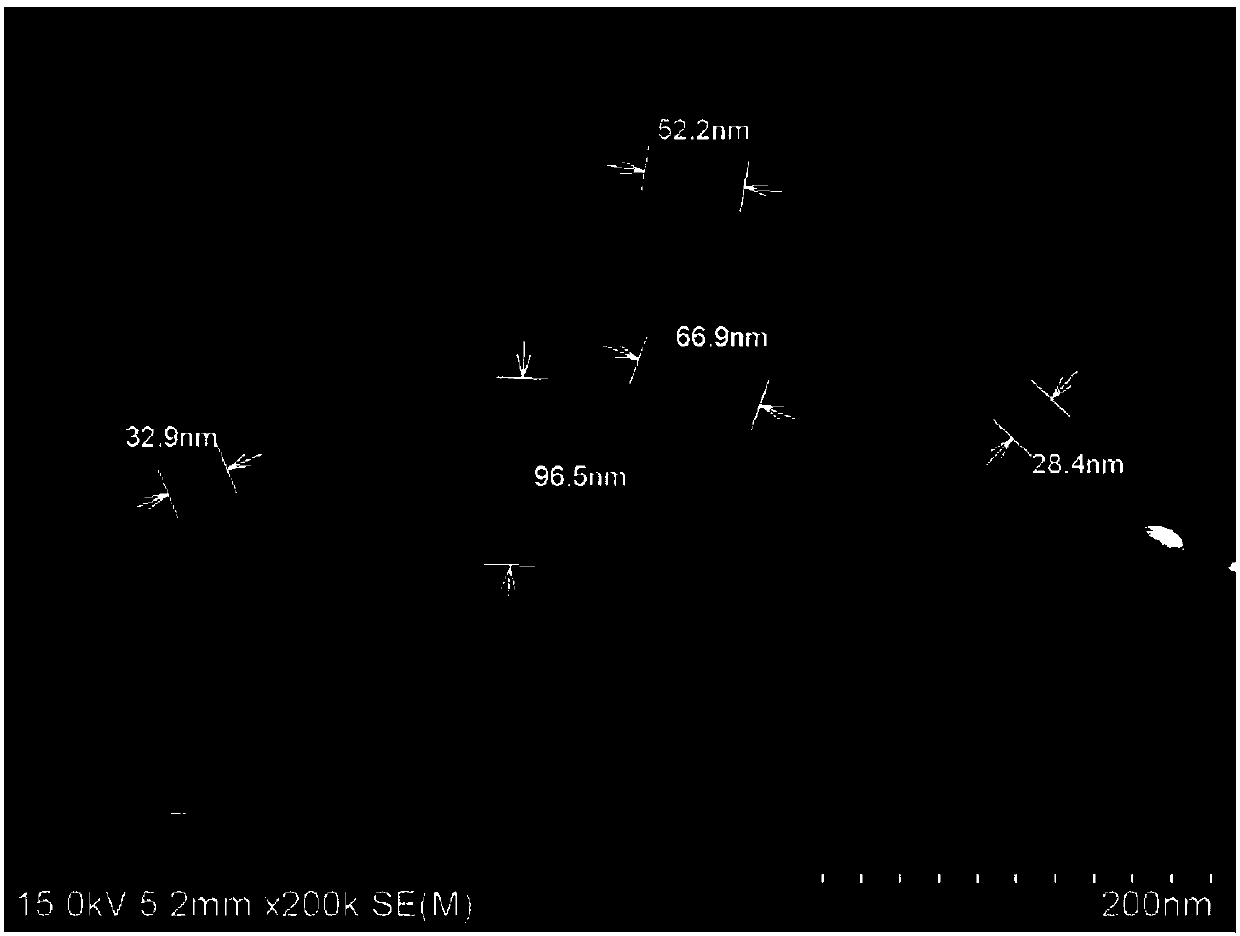

Embodiment 2

[0094] A preparation method of nano silver powder, comprising the steps of:

[0095] (1) Mix silver powder, ethanol, water, polyethylene glycol and sodium polyacrylate at 60°C, and stir to obtain a metal dispersion;

[0096] Wherein, according to weight fraction, silver powder accounts for 1% by weight of raw materials, polyethylene glycol accounts for 1% by weight of raw materials, sodium polyacrylate accounts for 0.3% by weight of raw materials, and ethanol accounts for 1% by weight of raw materials. %, water to make up the balance to 100%.

[0097] (2) Move the metal dispersion to the micro-fluidic equipment, and after the 200MPa micro-fluidic circulation treatment once, use the pinhole micro-fluidic equipment to perform the recirculation treatment at 300MPa once again to obtain the nano-metal solution.

[0098] (3) Precipitate the nano-silver obtained after the nano-metal solution is centrifuged, and dry to obtain a nano-silver powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com