A kind of cross-linked starch with high resistant starch content and preparation method thereof

A technology of high resistant starch and cross-linked starch, which is applied in the field of modified starch, can solve the problems of restricting the industrial production and application of cross-linked starch, low content of cross-linked starch resistant starch, and low production efficiency, so as to improve the cross-linking reaction Efficiency, enhanced health function, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Accurately take by weighing 25g potato starch (dry basis) and mix with double distilled water, the starch emulsion A that preparation obtains concentration is 40%, with 12% sodium tripolyphosphate-sodium trimetaphosphate (sodium tripolyphosphate: sodium trimetaphosphate =20:80) composite cross-linking agent and 10% anhydrous sodium sulfate were added to the starch milk, and the amount added was based on starch dry basis to obtain starch emulsion B. Adjust the pH of the starch emulsion B system to 9, stir evenly, and place in microwave In the synthesis reaction workstation, the reaction was carried out at 45°C for 2 minutes, and the power was set to 450W. During the microwave reaction, magnetic stirring was carried out at the same time to ensure the uniformity of heating. After the microwave reaction, adjust the pH of the starch emulsion to 6.0 with 1mol / L HCl solution to terminate the crosslinking reaction, then centrifuge under a centrifuge at 3000r / min, filter with suc...

Embodiment 2

[0024] Accurately take by weighing 25g potato starch (dry basis) and mix with double distilled water, prepare the starch emulsion that concentration is 40%, with 10% sodium tripolyphosphate-sodium trimetaphosphate (sodium tripolyphosphate: sodium trimetaphosphate =20:80) composite cross-linking agent and 10% anhydrous sodium sulfate were added to the starch milk, and the amount added was based on starch dry basis to obtain starch emulsion B. Adjust the pH of the starch emulsion B system to 10, stir evenly, and place in microwave In the synthesis reaction workstation, react at 50°C for 1.8min, and set the power to 500W. During the microwave reaction, magnetic stirring is carried out at the same time to ensure the uniformity of heating. After the microwave reaction, adjust the pH of the starch emulsion to 6.2 with 1mol / L HCl solution to terminate the crosslinking reaction, then centrifuge under a centrifuge at 3000r / min, filter with suction, wash, dry, pulverize, and sieve to pre...

Embodiment 3

[0026] Accurately take by weighing 25g potato starch (dry basis) and mix with double distilled water, prepare the starch emulsion that concentration is 30%, with 10% sodium tripolyphosphate-sodium trimetaphosphate (sodium tripolyphosphate: sodium trimetaphosphate =10:90) composite cross-linking agent and 10% anhydrous sodium sulfate were added to the starch emulsion, and the amount added was based on starch dry basis to obtain starch emulsion B. Adjust the pH of starch emulsion B system to 11, stir evenly, and place in microwave In the synthesis reaction workstation, react at 50°C for 1.2min, and set the power to 500W. During the microwave reaction, magnetic stirring is carried out at the same time to ensure the uniformity of heating. After the microwave reaction, adjust the pH of the starch emulsion to 6.5 with 1mol / L HCl solution to terminate the crosslinking reaction, then centrifuge under a centrifuge at 3000r / min, filter with suction, wash, dry, pulverize, and sieve to pre...

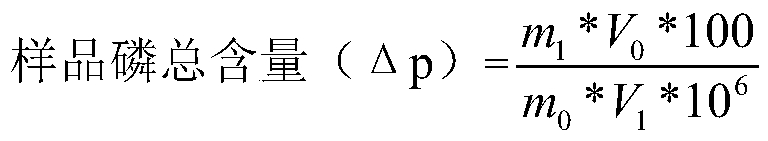

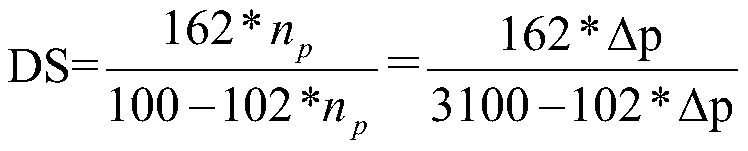

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com