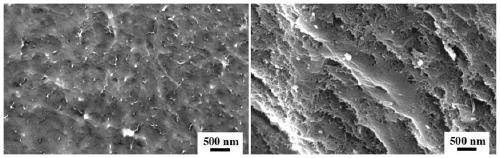

Preparation method of high strength hydrogel with simulated insect cuticle structure

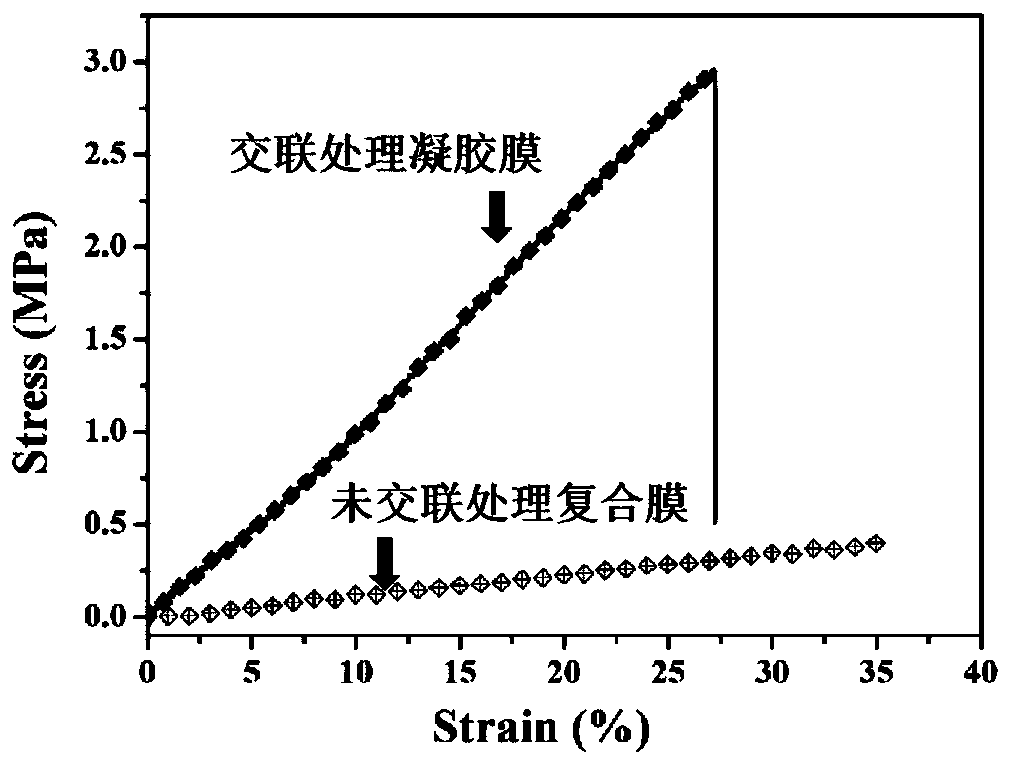

A high-strength, hydrogel technology, applied in the field of biomass materials, can solve the problems of poor bearing capacity and insufficient mechanical properties of gum-based hydrogels, improve efficiency, increase added value, and solve poor mechanical properties and bearing capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

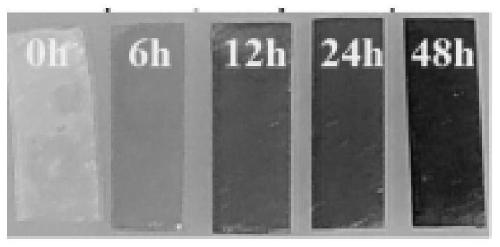

Method used

Image

Examples

preparation example Construction

[0031] The following are the specific steps of the preparation method of the high-strength hydrogel imitating the insect skin structure of the present invention:

[0032] 1) Put 10-20g of chitin powder (from discarded shrimp and crab shells) in 500-800ml, 30 wt%-35 wt% NaOH solution, mechanically stir at 80-90°C for 2-4 hours, the chitin Partially deacetylated. Through vacuum filtration, the obtained partial chitosan was fully washed until neutral.

[0033] 2) Dilute the above partially chitosan to 0.8-1wt% with 1 wt% acetic acid solution, and grind with a grinder to prepare a suspension of partially chitosan nanofibers. The grinding conditions are as follows: the rotational speed of the grinder is 1500 rpm / min, and the gap between the grinding discs is 0.25-0.35 mm.

[0034] 3) Dilute the suspension of the above-mentioned partial deacetylated chitin nanofibers to 0.3-0.5 wt % with distilled water, ultrasonically treat for 2-5 minutes, and then place the polytetrafluoroethyl...

Embodiment 1

[0039]1) Put 20g of chitin powder in 800ml, 33 wt% NaOH solution, and mechanically stir at 90°C for 4 hours to partially deacetylate chitin. The degree of deacetylation of chitin after elemental analysis is 40%. Through vacuum filtration, the obtained part of the chitosan sample was fully washed until neutral.

[0040] 2) Dilute the above partially chitosan to 0.8 wt% with 1 wt% acetic acid solution, and grind it through a grinder to prepare a suspension of partially chitosan nanofibers. The grinding conditions are as follows: the rotational speed of the grinder is 1500 rpm / min, and the gap between the grinding discs is 0.3 mm.

[0041] 3) Dilute the above part of chitosan nanofiber suspension to 0.5 wt % with distilled water, ultrasonic treatment for 2 minutes, then place the polytetrafluoroethylene membrane with a pore size of 0.1 micron in the sand core funnel of the vacuum filter, pass through The suspension was dehydrated by vacuum filtration to prepare a wet film of pa...

Embodiment 2

[0046] 1) Put 10g of chitin powder in 500ml of 30 wt% NaOH solution, and mechanically stir for 4 hours at 80°C to partially deacetylate chitin. The deacetylation degree of chitin obtained after elemental analysis is 30%. Through vacuum filtration, the obtained part of the chitosan sample was fully washed until neutral.

[0047] 2) Dilute the above partially deacetylated chitin to 1 wt% with acetic acid solution with a concentration of 1 wt%, and grind it through a grinder to prepare a suspension of partially chitin nanofibers. The grinding conditions are as follows: the rotational speed of the grinder is 1500 rpm / min, and the gap between the grinding discs is 0.35 mm.

[0048] 3) Dilute the above part of the chitosan nanofiber suspension to 0.3 wt % with distilled water, ultrasonicate for 5 minutes, then place the polytetrafluoroethylene membrane with a pore size of 0.1 micron in the sand core funnel of the vacuum filter, pass through The suspension was dehydrated by vacuum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com