Material used for preparing brush for motor of dust collector

A technology for vacuum cleaners and electric brushes is applied in the field of materials for electric brushes and electric brushes for electric vacuum cleaner motors, which can solve the problems of inability to meet the requirements for the use of electric brushes used in high-efficiency vacuum cleaner electric motors, poor stability, and low operating efficiency, and achieve the High efficiency, high stability and good commutation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

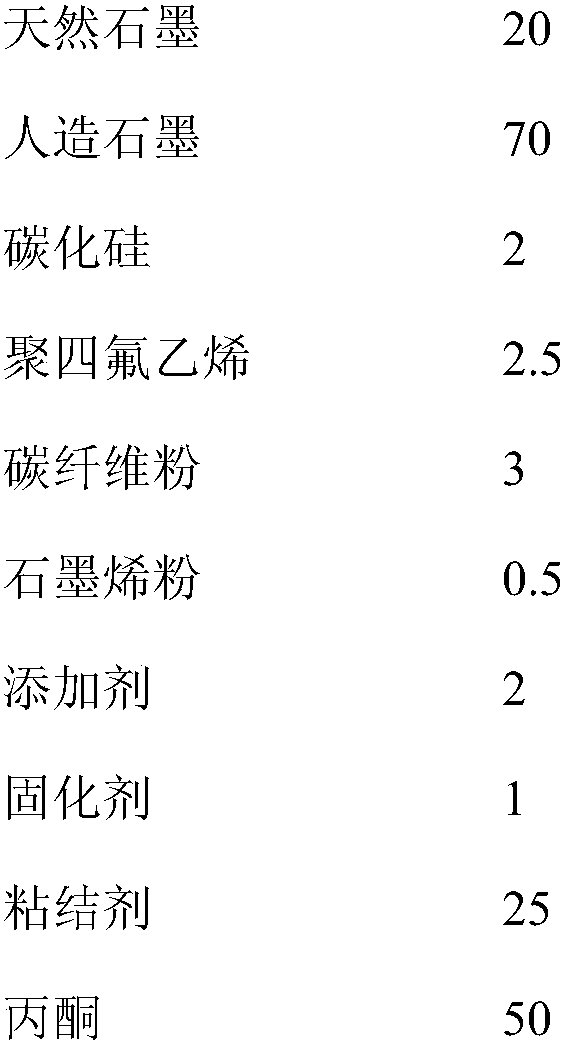

[0052] 1. Prepare materials according to the following proportions by weight (parts):

[0053]

[0054] Among them, the additive is one or a combination of molybdenum disulfide, tungsten disulfide, and talcum powder; the binder is selected from bisphenol A epoxy resin, and its epoxy value is 0.25-0.45; the curing agent is selected from epoxy resin latent type Curing agent T-31 curing agent (Changzhou Shanfeng Chemical Co., Ltd.).

[0055] 2. Put natural graphite, artificial graphite, silicon carbide, polytetrafluoroethylene, carbon fiber powder, graphene powder, additives and curing agent in the kneading pot, turn on the rotating device of the kneading pot, and stop after mixing for 1.5 hours at room temperature. The matrix powder is prepared; the binder is dissolved in acetone, stirred and mixed evenly to dissolve, and the binder solution is obtained; the binder solution is added to the matrix powder and stirred, mixed evenly, and stirred for 1.5h, After mixing evenly, ta...

Embodiment 2

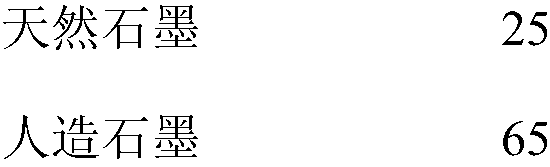

[0064] 1. Prepare materials according to the following proportions by weight (parts):

[0065]

[0066]

[0067] Among them, the additive is one or a combination of molybdenum disulfide, tungsten disulfide, and talcum powder; the binder is selected from bisphenol A epoxy resin, and its epoxy value is 0.25-0.45; the curing agent is selected from epoxy resin latent type Curing agent T-31 curing agent (Changzhou Shanfeng Chemical Co., Ltd.).

[0068] 2. Put natural graphite, artificial graphite, silicon carbide, polytetrafluoroethylene, carbon fiber powder, graphene powder, additives and curing agent in the kneading pot, turn on the rotating device of the kneading pot, and stop after mixing for 1.5 hours at room temperature. The matrix powder is prepared; the binder is dissolved in acetone, stirred and mixed evenly to dissolve, and the binder solution is obtained; the binder solution is added to the matrix powder and stirred, mixed evenly, and stirred for 1.5h, After mixin...

Embodiment 3

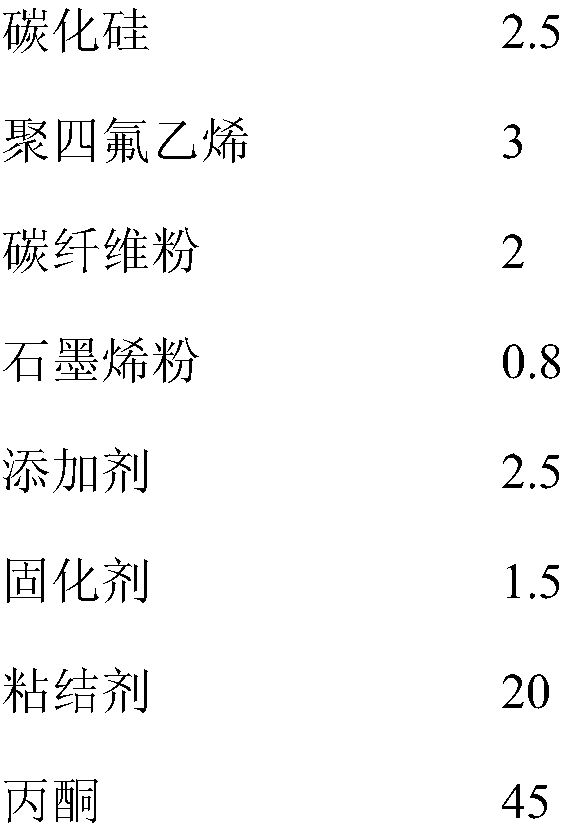

[0078] 1. Prepare materials according to the following proportions by weight (parts):

[0079]

[0080] Among them, the additive is one or a combination of molybdenum disulfide, tungsten disulfide, and talcum powder; the binder is selected from bisphenol A epoxy resin, and its epoxy value is 0.25-0.45; the curing agent is selected from epoxy resin latent type Curing agent T-31 curing agent (Changzhou Shanfeng Chemical Co., Ltd.).

[0081] 2. Put natural graphite, artificial graphite, silicon carbide, polytetrafluoroethylene, carbon fiber powder, graphene powder, additives and curing agent in the kneading pot, turn on the rotating device of the kneading pot, and stop after mixing for 1.5 hours at room temperature. The matrix powder is prepared; the binder is dissolved in acetone, stirred and mixed evenly to dissolve, and the binder solution is obtained; the binder solution is added to the matrix powder and stirred, mixed evenly, and stirred for 1.5h, After mixing evenly, ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com