Method for producing 3D printed artificial bone

A 3D printing and manufacturing method technology, which is applied in the medical field, can solve the problems of drugs staying in the place where they need to be effective, increasing bone mass, and failing to meet the requirements of orthopedic surgery, achieving precise slow-release drug release effects and increasing bone mass. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

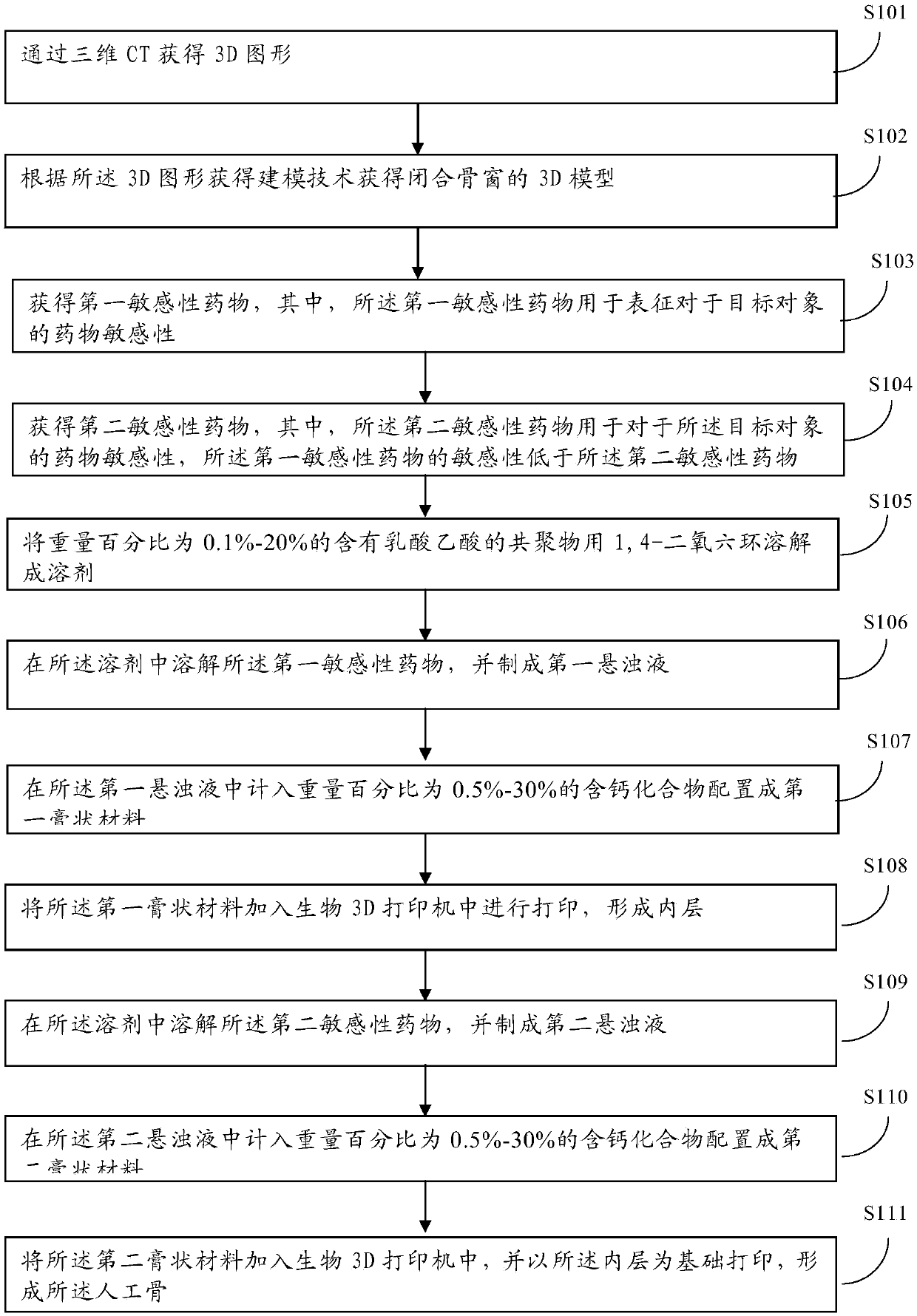

[0038] figure 1 This is a schematic flow chart of a manufacturing method of 3D printed artificial bone provided by an embodiment of this application. Such as figure 1 As shown, the method includes:

[0039] Step 101: Obtain 3D graphics through 3D CT;

[0040] Specifically, by performing a three-dimensional CT on the affected area of the patient, a 3D stereoscopic image of the affected area is obtained, and the above-mentioned 3D stereoscopic image can truly see the shape of the bones of the affected area. For example, a patient has a bone tumor. After the bone tumor is surgically removed, there will be a gap in the bone in the affected area. The gap is determined by the size and shape of the bone tumor. It can be said that the gap after the removal of the bone tumor is all It is not the same, so through three-dimensional CT, you can get the same shape and size as the patient's bone gap.

[0041] Step 102: Obtain a 3D model of the closed bone window through modeling technology acc...

Embodiment 2

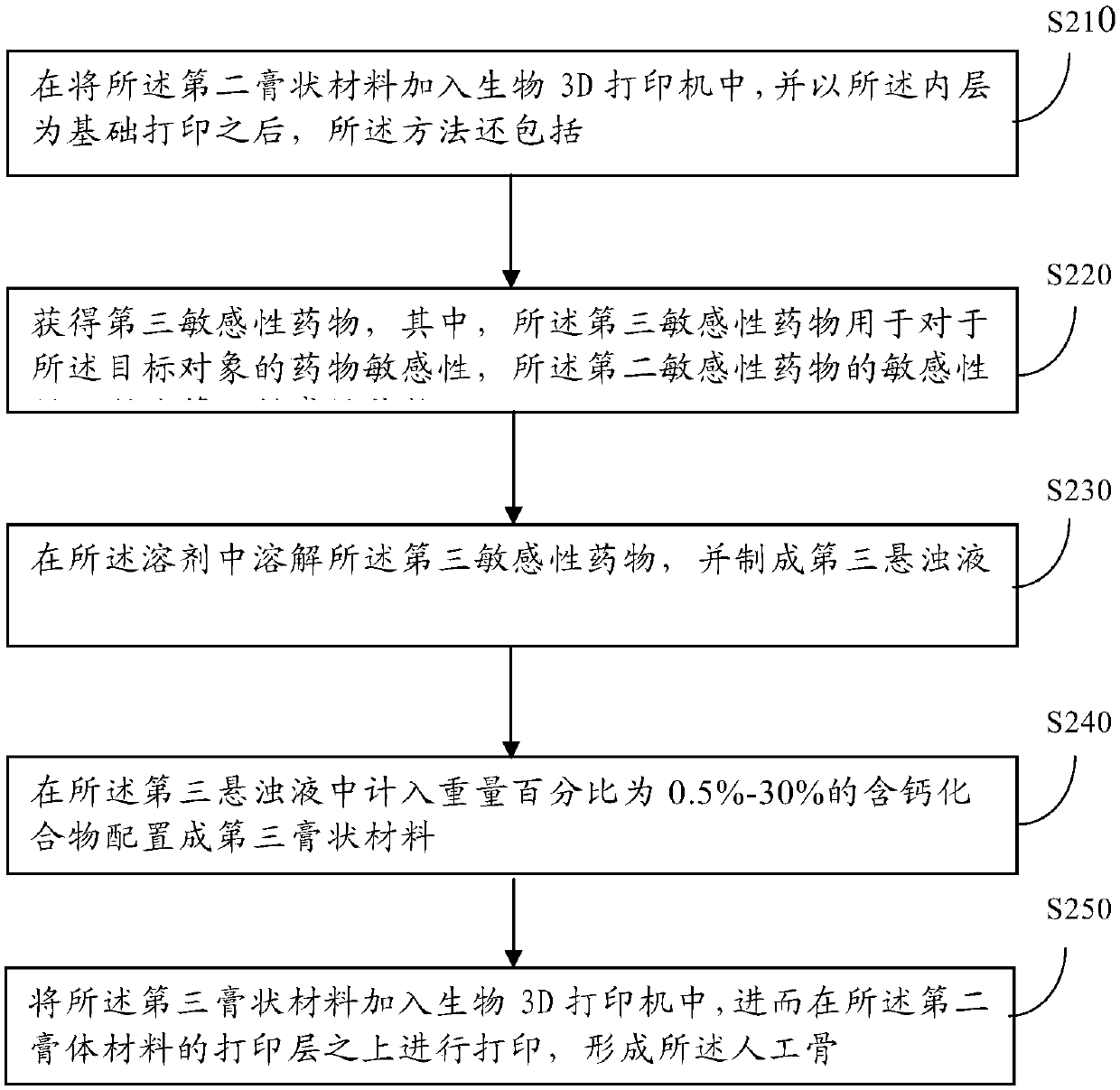

[0063] In order to achieve the use of more moderately sensitive drugs and further enhance the sustained release effect, the embodiments of the present application also provide a manufacturing method of 3D printed artificial bone, such as figure 2 As shown, the method includes:

[0064] Step 210: After adding the second paste-like material to the biological 3D printer and printing on the basis of the inner layer, the method further includes:

[0065] Step 220: Obtain a third sensitive drug, wherein the third sensitive drug is used for drug sensitivity to the target object, and the sensitivity of the second sensitive drug is lower than that of the third sensitive drug ;

[0066] Step 230: Dissolve the third sensitive drug in the solvent and prepare a third suspension;

[0067] Step 240: adding 0.5%-30% by weight of the calcium-containing compound in the third suspension to prepare a third paste material;

[0068] Step 250: Add the third paste material to a bio-3D printer, and then print...

Embodiment 3

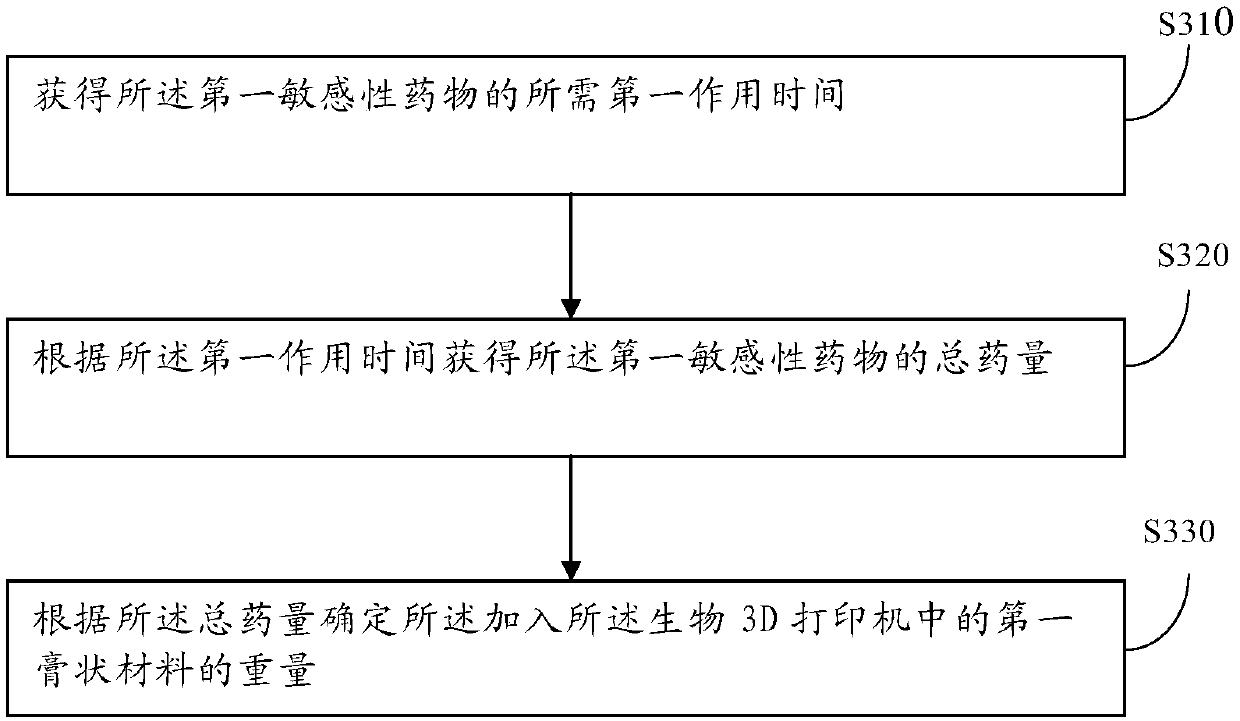

[0071] In order to further improve the slow-release effect, the embodiments of the present application also provide a manufacturing method of 3D printed artificial bone, such as image 3 As shown, the method includes:

[0072] Step 310: Obtain the required first action time of the first sensitive drug;

[0073] Step 320: Obtain the total amount of the first sensitive drug according to the first action time;

[0074] Step 330: Determine the weight of the first paste material added to the biological 3D printer according to the total amount of medicine.

[0075] For the embodiments of the present application, different target objects may require different sustained release times according to their disease conditions, individual physical conditions, etc. Therefore, it is necessary to first determine the required release time of the sensitive drug. Specifically, for the first A sensitive drug needs the first time of action. Further, for the second sensitive drug, the release time correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com