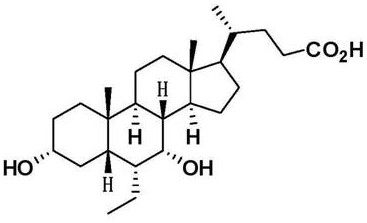

A kind of preparation method of obeticholic acid dimer

A technology of obeticholic acid dimer and dimer, which is applied in the field of preparation of obeticholic acid dimer, can solve the problems of many by-products, inability to use impurities for research, and low product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

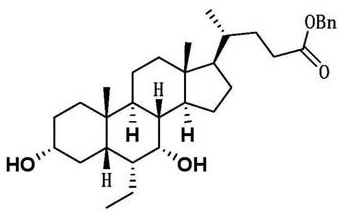

[0057] Step a: Preparation of benzyl 3α,7α-dihydroxy-6α-ethyl-5β-cholanate (VI)

[0058] At room temperature, add 10.0 g of 3α,7α-dihydroxy-6α-ethyl-5β-cholanic acid (VII), 5.0 g of potassium carbonate and 100 ml of N,N-dimethylformamide into the reaction flask, 6.1 g of benzyl bromide (1.5 eq) was added with stirring, and the reaction was stirred for 10 h. The reaction solution was poured into 100 ml of saturated sodium chloride solution, 100 ml of ethyl acetate was added for extraction, and the organic phase was collected. Wash the organic phase twice with 50ml of 10% sodium chloride aqueous solution, wash once with 50ml of water, add 20g of anhydrous magnesium sulfate to dry for 2h, filter, and concentrate the organic phase to obtain 11.24g of 3α,7α-dihydroxy-6α-ethyl-5β - Benzyl cholanoate (VI), content 96.7%, yield 92.4%.

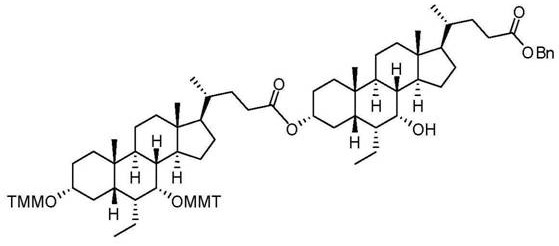

[0059] Step b: Preparation of 3α,7α-bis-(4-methoxytriphenylmethyl)-6α-ethyl-5β-cholanoic acid benzyl ester (Ⅴ)

[0060] Control the temperature at ...

Embodiment 2

[0070] Step a: Preparation of benzyl 3α,7α-dihydroxy-6α-ethyl-5β-cholanate (VI)

[0071] 10.0 g of 3α, 7α-dihydroxy-6α-ethyl-5β-cholanic acid (VII), 11.2 g of cesium carbonate and 100 ml of acetonitrile were added to the reaction flask, and 6.1 g of benzyl bromide (1.5 eq), the reaction was stirred for 10h. After the reaction solution was concentrated under reduced pressure, 100 ml of saturated sodium chloride solution was added, and extracted with 100 ml of ethyl acetate. Wash the organic phase twice with 50ml of 10% sodium chloride aqueous solution, and once with 50ml of water, add 20g of anhydrous magnesium sulfate to dry for 3h, filter, and concentrate the organic phase to obtain 11.36g of 3α,7α-dihydroxy-6α-ethyl-5β - benzyl cholanoate (VI), content 97.6%, yield 93.4%.

[0072] Step b: Preparation of 3α,7α-bis-(4-methoxytriphenylmethyl)-6α-ethyl-5β-cholanoic acid benzyl ester (Ⅴ)

[0073] Control the temperature at -5~0°C, add 7g of 3α,7α-dihydroxy-6α-ethyl-5β-benzyl c...

Embodiment 3

[0083] Step a: Preparation of benzyl 3α,7α-dihydroxy-6α-ethyl-5β-cholanate (VI)

[0084] Add 10.0 g of 3α,7α-dihydroxy-6α-ethyl-5β-cholanic acid (VII), 5.4 g of DBU and 100 ml of N,N-dimethylformamide into the reaction flask, and add 6.1 g of benzyl bromide (1.5eq), the reaction was stirred for 10h. After the reaction solution was concentrated under reduced pressure, 100 ml of saturated sodium chloride solution was added, and extracted with 100 ml of ethyl acetate. The organic phase was washed twice with 50ml of 10% sodium chloride aqueous solution, washed once with 50ml of water, dried with 20g of anhydrous magnesium sulfate for 2.5h, filtered, and the organic phase was concentrated to obtain 11.31g of 3α,7α-dihydroxy-6α-ethyl- Benzyl 5β-cholanoate (Ⅵ), content 96.9%, yield 93%.

[0085] Step b: Preparation of 3α,7α-bis-(4-methoxytriphenylmethyl)-6α-ethyl-5β-cholanoic acid benzyl ester (Ⅴ)

[0086] Control the temperature at -5~0°C, add 7g of 3α,7α-dihydroxy-6α-ethyl-5β-ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com