Weather-proofing sealant used for bottom of lens and preparation method thereof

A weather-resistant adhesive and modification technology, which is applied in chemical instruments and methods, adhesives, and other chemical processes, can solve problems such as high cost, poor sealing oil resistance, and difficult cleaning, and achieve low cost, good elasticity, and excellent adhesion. The effect of knot properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The special weather-resistant adhesive at the bottom of the mirror in this embodiment 1 is made by the following steps and includes the following steps:

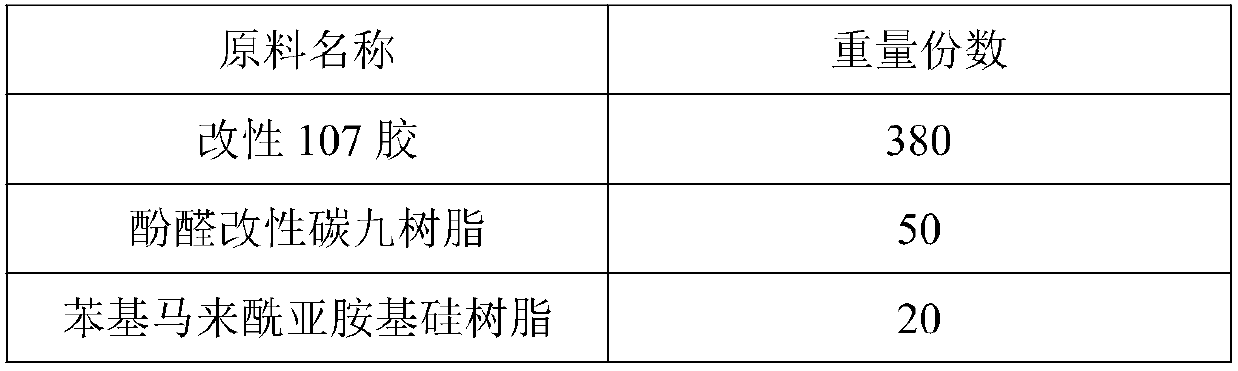

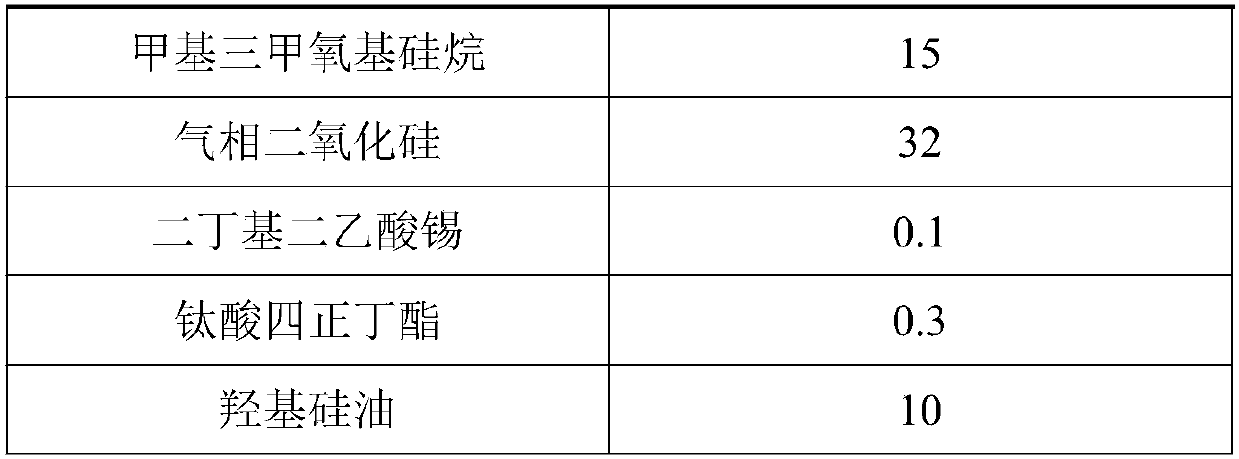

[0018] 1) Weighing raw materials;

[0019] 1) Add modified 107 glue, phenolic modified C9 resin, phenylmaleimide-based silicone resin and methyltrimethoxysilane, push the machine, stir for 5 minutes, vacuumize to -0.09MPa, and then control Speed 100r / min, stirring for 15 minutes;

[0020] 2) Add gas-phase silica, stir well, then evacuate to -0.09MPa, then control the speed at 600r / min, and stir for 20min;

[0021] 3) Stop the vacuum, adjust the speed to 300r / min, add dibutyl tin diacetate, tetra-n-butyl titanate and hydroxyl silicone oil, then vacuumize to -0.09, stir for 30 minutes and discharge;

[0022] 4) The consistency is controlled at 8.5 to 9.0.

[0023] 6) Shut down, empty, and check that the viscosity is in the range of 8.5 to 9.0, and the product is qualified and discharged.

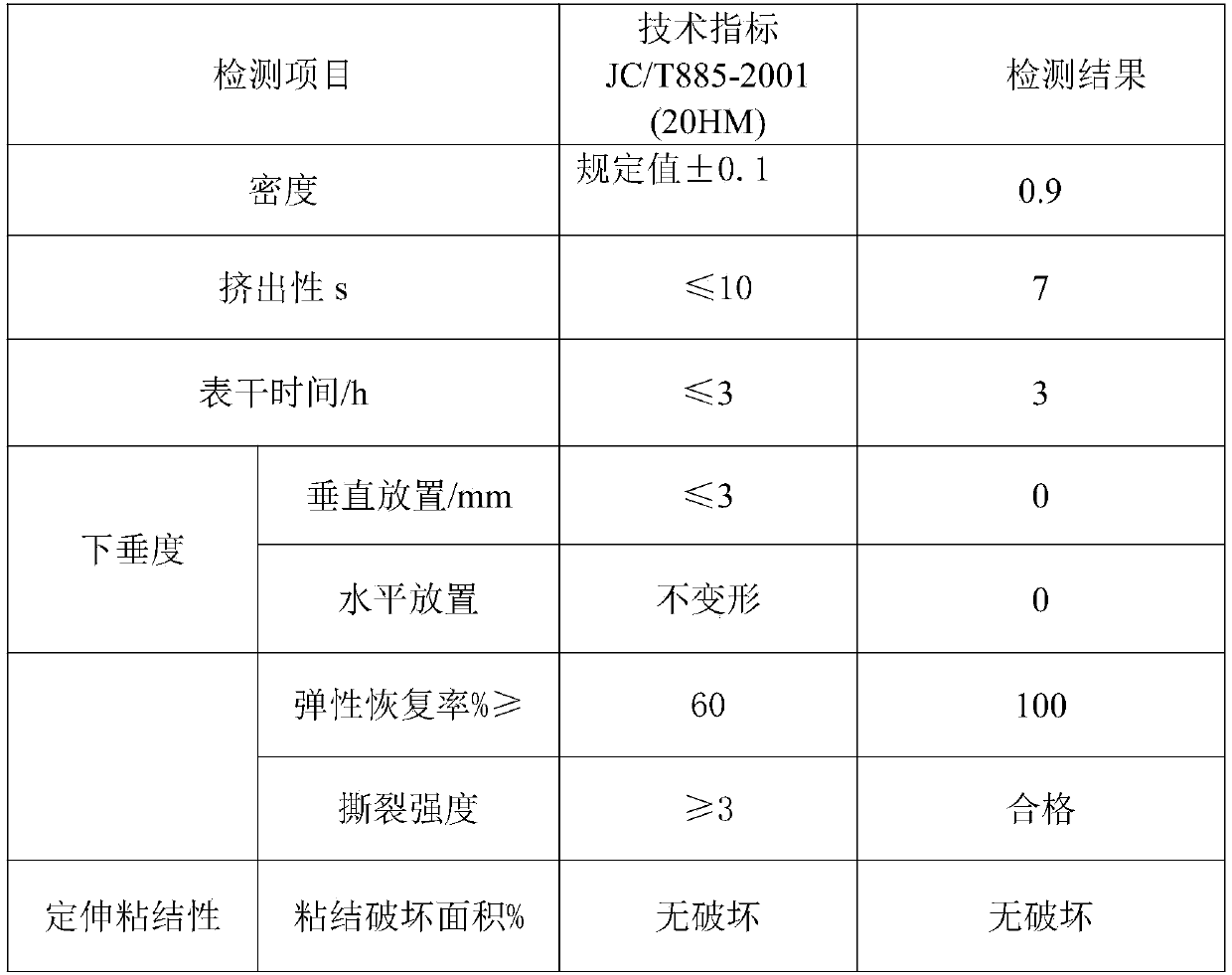

[0024] In Table 1 Exampl...

Embodiment 2

[0030] The special weather-resistant adhesive at the bottom of the mirror in this embodiment 2 is made by the following steps and includes the following steps:

[0031] 2) Weighing raw materials;

[0032] 1) Add modified 107 glue, phenolic modified C9 resin, phenylmaleimide-based silicone resin and methyltrimethoxysilane, push the machine, stir for 5 minutes, vacuumize to -0.09MPa, and then control Speed 100r / min, stirring for 15 minutes;

[0033] 2) Add gas-phase silica, stir well, then evacuate to -0.09MPa, then control the speed at 600r / min, and stir for 20min;

[0034] 3) Stop the vacuum, adjust the speed to 300r / min, add dibutyl tin diacetate, tetra-n-butyl titanate and hydroxyl silicone oil, then vacuumize to -0.09, stir for 30 minutes and discharge;

[0035] 4) The consistency is controlled at 8.5 to 9.0.

[0036] 6) Shut down, empty, and check that the viscosity is in the range of 8.5 to 9.0, and the product is qualified and discharged.

[0037] In Table 3 Exampl...

Embodiment 3

[0042] The special weather-resistant adhesive at the bottom of the mirror in this embodiment 3 is made by the following steps and includes the following steps:

[0043] 3) Weighing raw materials;

[0044] 1) Add modified 107 glue, phenolic modified C9 resin, phenylmaleimide-based silicone resin and methyltrimethoxysilane, push the machine, stir for 5 minutes, vacuumize to -0.09MPa, and then control Speed 100r / min, stirring for 15 minutes;

[0045] 2) Add gas-phase silica, stir well, then evacuate to -0.09MPa, then control the speed at 600r / min, and stir for 20min;

[0046] 3) Stop the vacuum, adjust the speed to 300r / min, add dibutyl tin diacetate, tetra-n-butyl titanate and hydroxyl silicone oil, then vacuumize to -0.09, stir for 30 minutes and discharge;

[0047] 4) The consistency is controlled at 8.5 to 9.0.

[0048] 6) Shut down, empty, and check that the viscosity is in the range of 8.5 to 9.0, and the product is qualified and discharged.

[0049] In Table 5 Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com