Method for PVD film plating on surfaces of workpieces

A workpiece surface and workpiece technology, applied in the field of PVD coating on the workpiece surface, can solve the problems of product compactness and poor corrosion resistance, and achieve the effect of denser film structure and finer film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The workpiece to be plated in this embodiment is made of skd11 material.

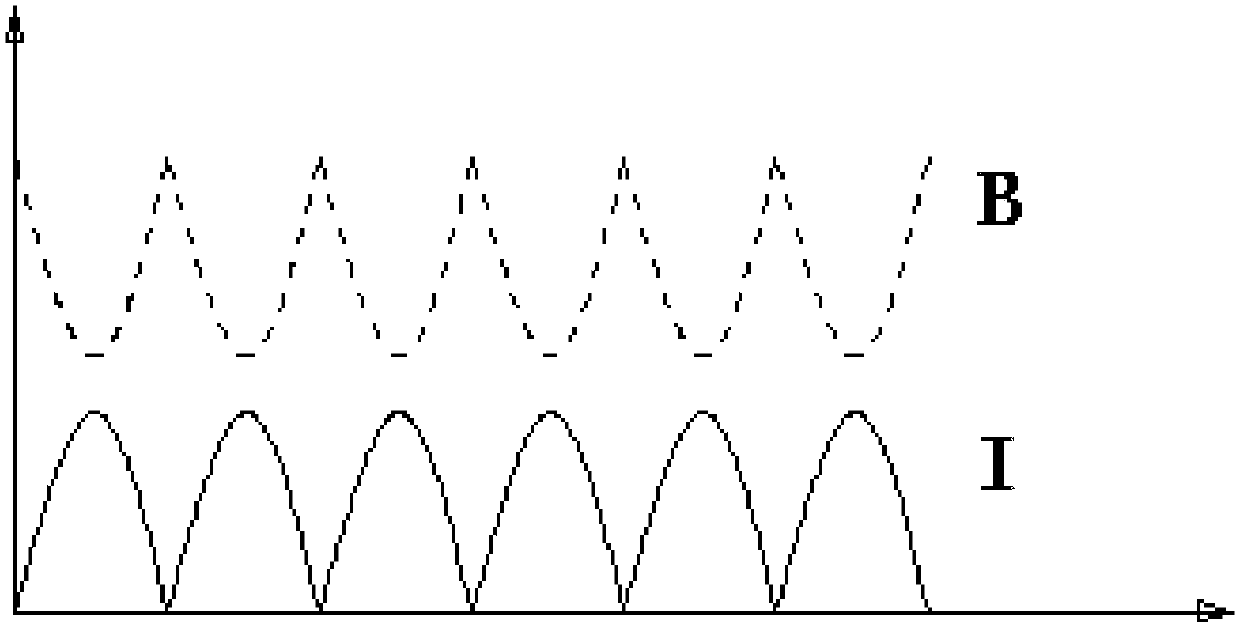

[0030] In this example, if figure 1 Shown, where, the target current according to I=10+140∣sin(∏t 1 )∣regularly changing periodically; the corresponding magnetic field strength is according to B=1000-900∣sin(∏t 1 )∣regularly changing periodically, t 1 is the coating time, the change cycle of the current and the magnetic field is 1 second, the unit of the above-mentioned target current is A, and the unit of the magnetic field strength is Gs. in, figure 1 Among them, B represents the change cycle of the magnetic field intensity, and I represents the target electrorheological cycle.

[0031] Grind the selected workpiece to be coated with metallographic sandpaper or grinding wheel and then clean it. After cleaning with alkaline reagent, rinse it to neutral and dry it; then, wash and dry the workpiece to be coated Put the work into the coating chamber for fixing;

[0032] Then, vacuumize the coa...

Embodiment 2

[0037] The workpiece to be plated in this embodiment is made of skd11 material.

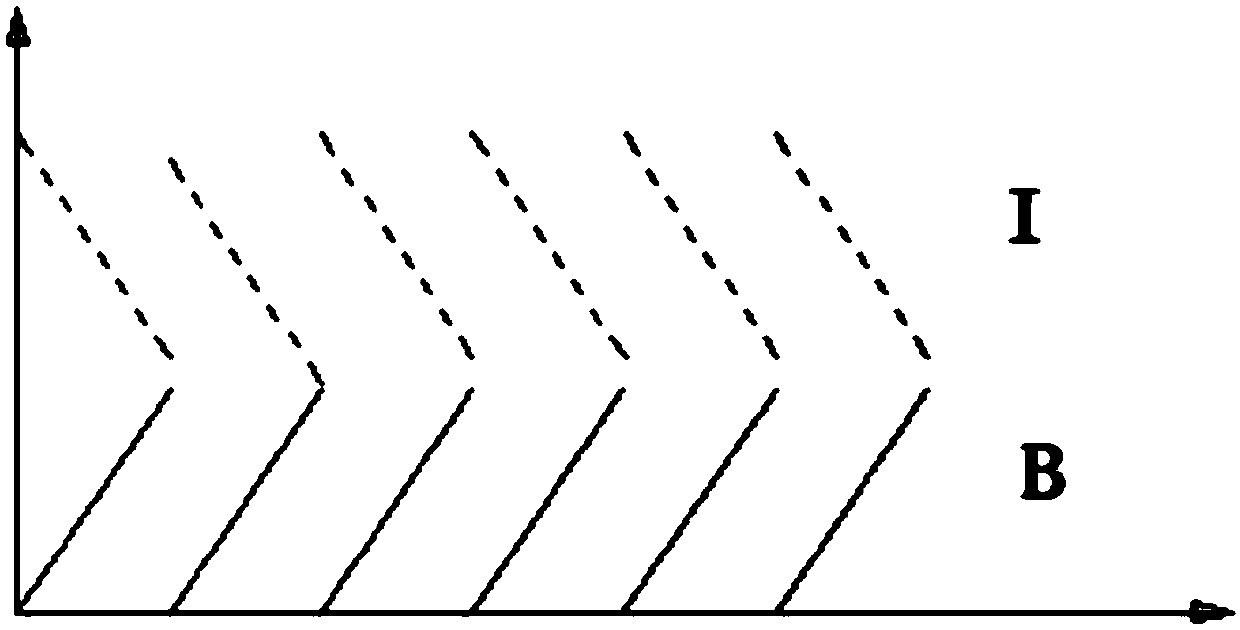

[0038] In this example, if figure 2 Shown, among them, target current I=150-140[t 2 -(k-1)], magnetic field strength B=100+900[t 2 -(k-1)],t 2 is the coating time, k is the number of repeated cycles, the change cycle of the current and the magnetic field is 1 second, the unit of the above-mentioned target current is A, and the unit of the magnetic field strength is Gs. in, figure 1 Among them, B represents the change cycle of the magnetic field intensity, and I represents the change cycle of the target current.

[0039] Grind the selected workpiece to be coated with metallographic sandpaper or grinding wheel and then clean it. After cleaning with alkaline reagent, rinse it to neutral and dry it; then, wash and dry the workpiece to be coated Put the work into the coating chamber for fixing;

[0040] Then, vacuumize the coating chamber to make the vacuum in the coating chamber higher than 2....

Embodiment 3

[0045] In this example, if figure 1 Shown, where, the target current according to I=10+140∣sin(∏t 1 )∣regularly changing periodically; the corresponding magnetic field strength is according to B=1000-900∣sin(∏t 1 )∣regularly changing periodically, t 1 is the coating time, the change cycle of the current and the magnetic field is 1 second, the unit of the above current is A, and the unit of the magnetic field strength is Gs.

[0046] Grind the selected workpiece to be coated with metallographic sandpaper or grinding wheel and then clean it. After cleaning with alkaline reagent, rinse it to neutral and dry it; then, wash and dry the workpiece to be coated Put the work into the coating chamber for fixing;

[0047] Then, vacuumize the coating chamber to make the vacuum in the coating chamber higher than 1.5x10 -3 pa, heated to 220°C; pass in argon (Ar), adjust the magnetic field to 600Gs, adjust the target current to 75A, turn on the power, and bombard the surface of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com