Pyrite structural iron-based ternary chalcogenide single crystal material and preparation method thereof

A single crystal material and structural iron technology, applied in the field of material science, can solve the problems of easy impurity, complexity, and complex requirements, and achieve the effect of good crystallization performance, simple equipment, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

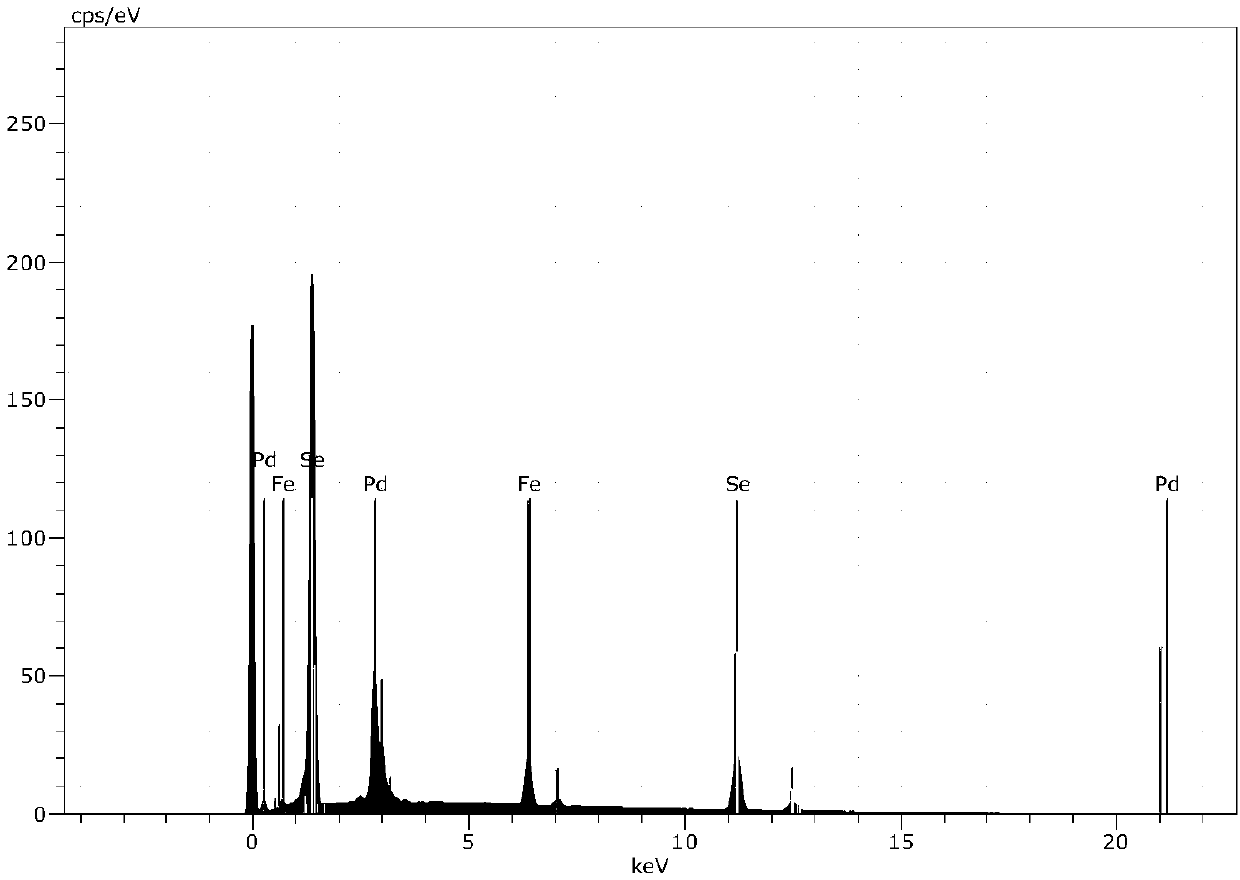

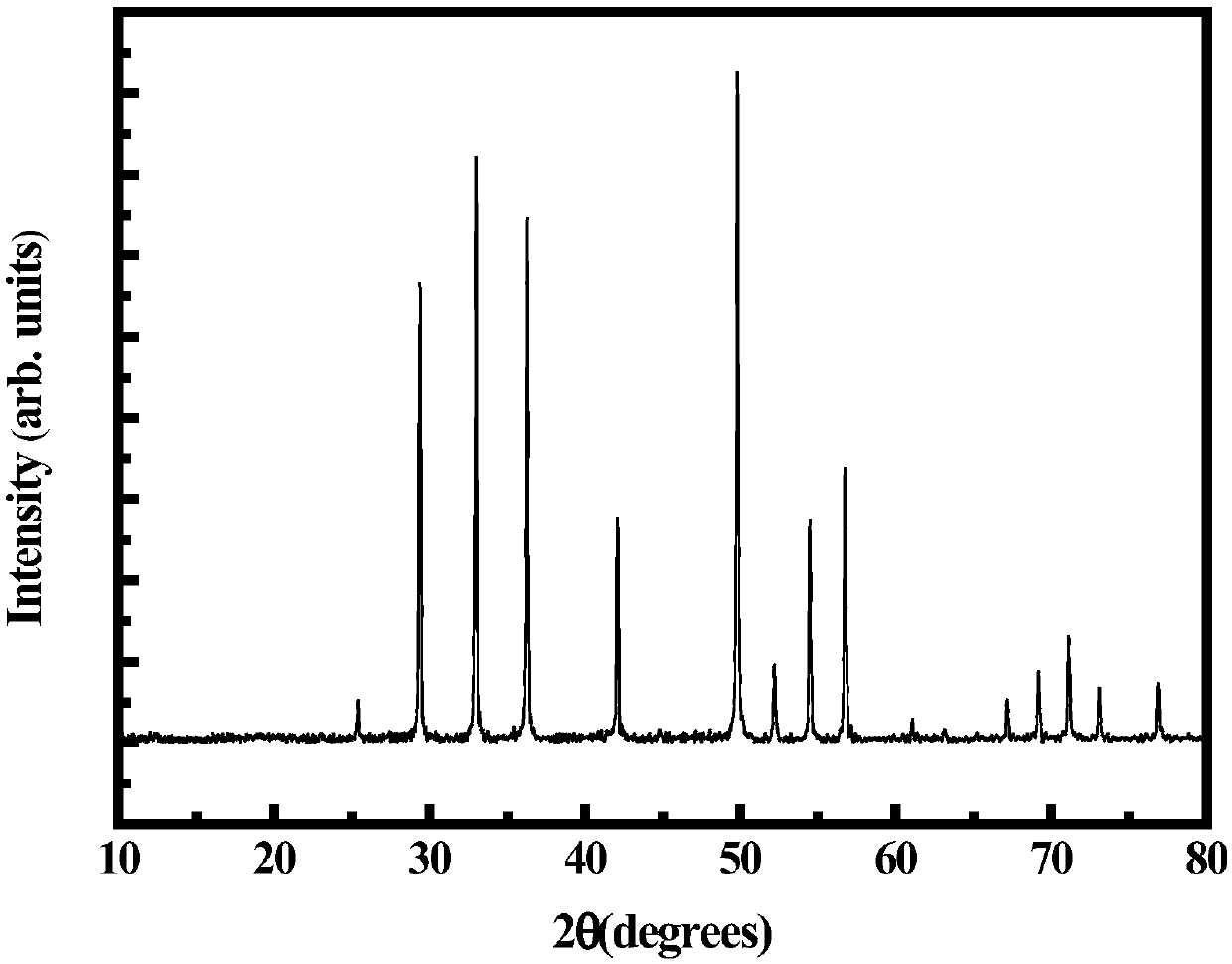

[0029] This embodiment is a pyrite structure iron chalcogen single crystal FePd 2 Se 6 The preparation process and its structural, electrical, and magnetic tests.

[0030] 1. Single crystal preparation

[0031] 1), weighing raw materials and sealing

[0032] Weigh 0.1071g of Fe block, 0.4083g of Pd block and 1.5152g of Se powder, grind and mix them and put them into an alumina crucible, then put the crucible into a quartz tube. Vacuum the quartz tube and then fill it with argon, repeat 5 times, and finally evacuate again, the pressure is 10 -3 Pa;

[0033] 2), heating and annealing process

[0034] Put the quartz tube sealed with the crucible in the high-temperature annealing furnace, and start to set the temperature program. It took 12 hours to raise the room temperature to 300°C; keep warm at 300°C for 12 hours; rise from 300°C to 900°C and take 12 hours; keep warm at 900°C for 4 hours; cool down from 900°C to 300°C and take more than 200 hours. During every 12 hours,...

Embodiment 2

[0046] This embodiment is a pyrite structure iron chalcogen single crystal FePd 2 Se 6 preparation process and its structure.

[0047] 1. Single crystal preparation

[0048] 1), weighing raw materials and sealing

[0049] Weigh a certain mass of Fe powder, Pd powder and Se powder with the ratio of Fe:Pd:Se 3:1:15, grind and mix them, put them into an alumina crucible, and then put the crucible into a quartz tube. Vacuum the quartz tube and then fill it with argon, repeat 5 times, and finally evacuate again, the pressure is 10 -2 Pa;

[0050] 2), heating and annealing process

[0051] Put the quartz tube sealed with the crucible in the high-temperature annealing furnace, and start to set the temperature program. It took 12 hours to raise the room temperature to 300°C; 12 hours to keep at 300°C; 24 hours to rise from 300°C to 950°C; 4 hours to keep at 900°C; 200 hours to cool down from 950°C to 300°C. Every 24 hours, make the furnace slightly vibrate or shake for 1 minute...

Embodiment 3

[0055] This embodiment is a pyrite structure iron chalcogen single crystal FePd 2 Se 6 preparation process and its structure.

[0056] 1. Single crystal preparation

[0057] 1), weighing raw materials and sealing

[0058] Weigh a certain mass of Fe powder, Pd powder and Se powder with the ratio of Fe:Pd:Se 1:3:20, grind and mix them, put them into an alumina crucible, and then put the crucible into a quartz tube. Vacuum the quartz tube and then fill it with argon, repeat 5 times, and finally evacuate again, the pressure is 10 -2 Pa;

[0059] 2), heating and annealing process

[0060] Put the quartz tube sealed with the crucible in the high-temperature annealing furnace, and start to set the temperature program. It takes 10 hours to raise the room temperature to 300°C; 10 hours to keep at 300°C; 24 hours to rise from 300°C to 1000°C; 4 hours to keep at 1000°C; 220 hours to cool down from 1000°C to 300°C. Every 48 hours, make the furnace slightly vibrate or shake for 2 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com