FOA optimization based GRNN fault forecasting method for rotary machine

A fault prediction, rotating machinery technology, applied in mechanical bearing testing, neural learning methods, instruments, etc., can solve problems such as endangering the life safety of surrounding workers, production line breakage, and corporate economic losses, shortening the setup time and improving accuracy. and efficiency, the effect of reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention clearer, the present invention is described below through specific embodiments shown in the accompanying drawings. It should be understood, however, that these descriptions are exemplary only and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

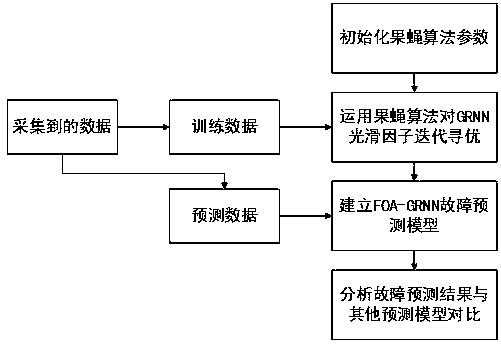

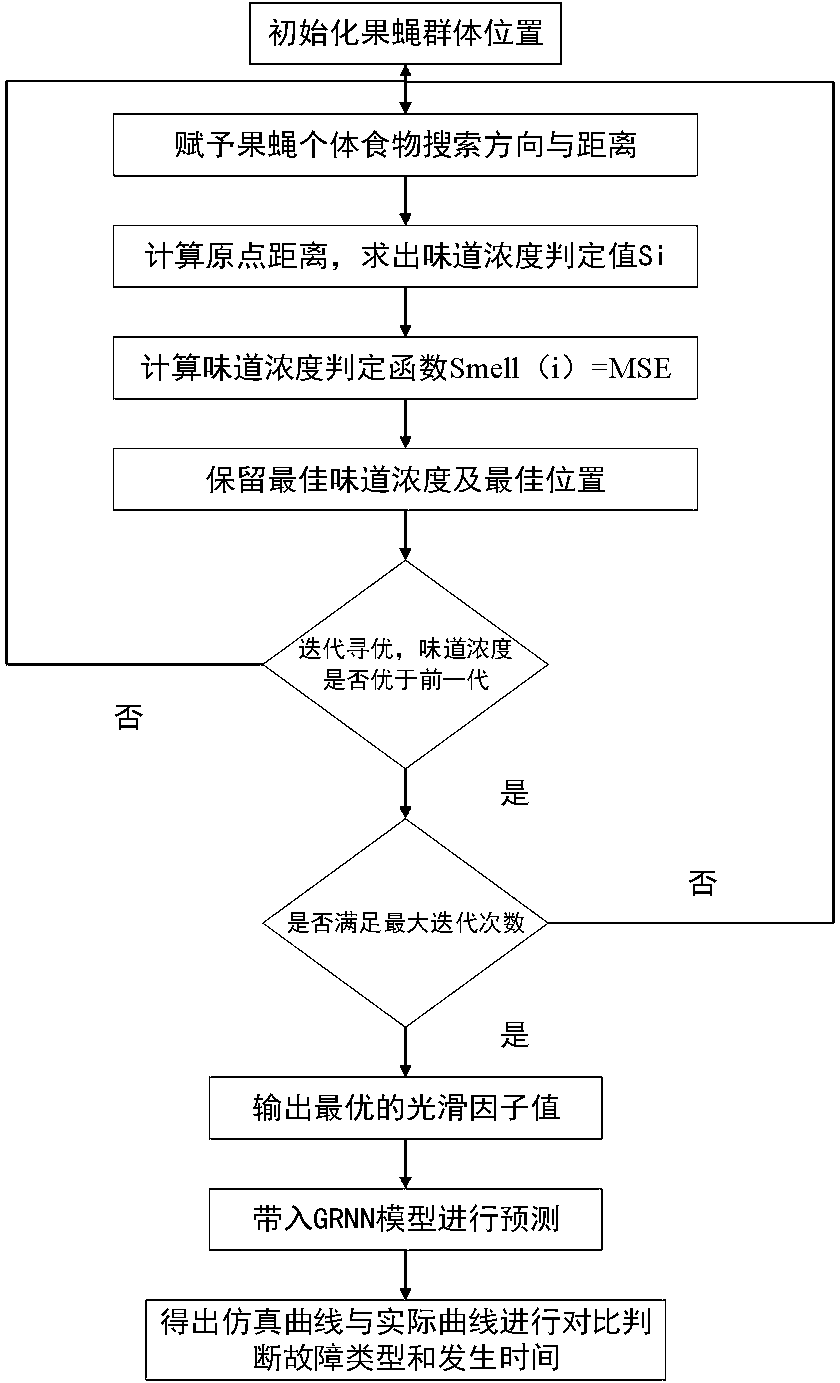

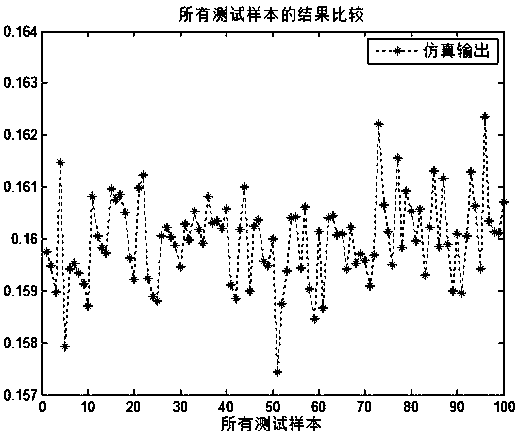

[0030] Such as Figure 1 to Figure 4 As shown, the specific implementation mode adopts the following technical solutions: its implementation steps are as follows:

[0031] (1) Using the experimental data of rolling bearings in Cincinnati, select 1100 points equidistantly from the experimental data of 33 days.

[0032] (2) Divide the discrete data of the signal collected in step (1) into two parts, training data and prediction data, in which the first 1000 po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com