Acid-modified g-C3N4 photocatalyst and preparation and application thereof

A photocatalyst and acid modification technology, applied in the field of photocatalysis, can solve the problems of high cost of raw materials, failure to meet industrial requirements, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

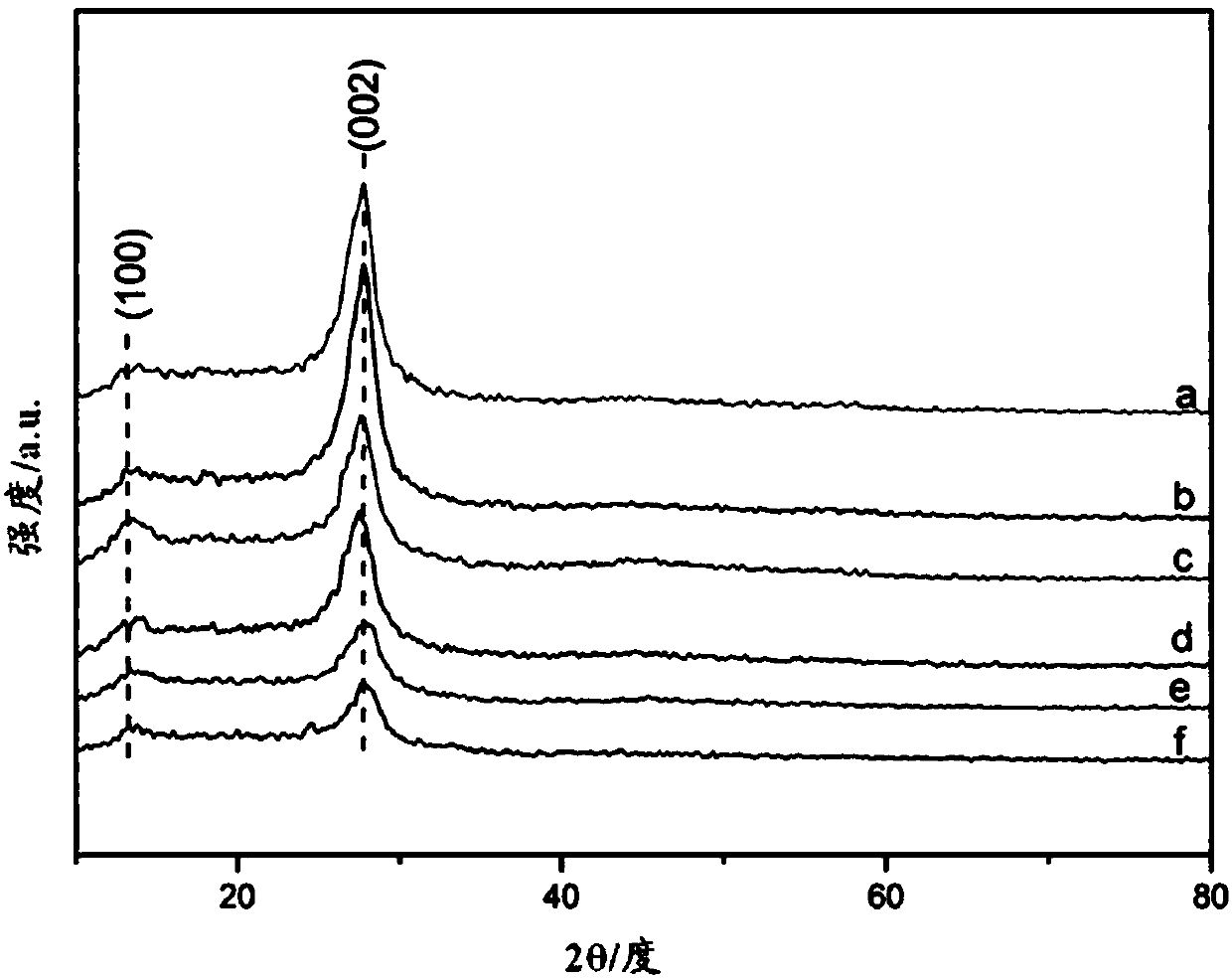

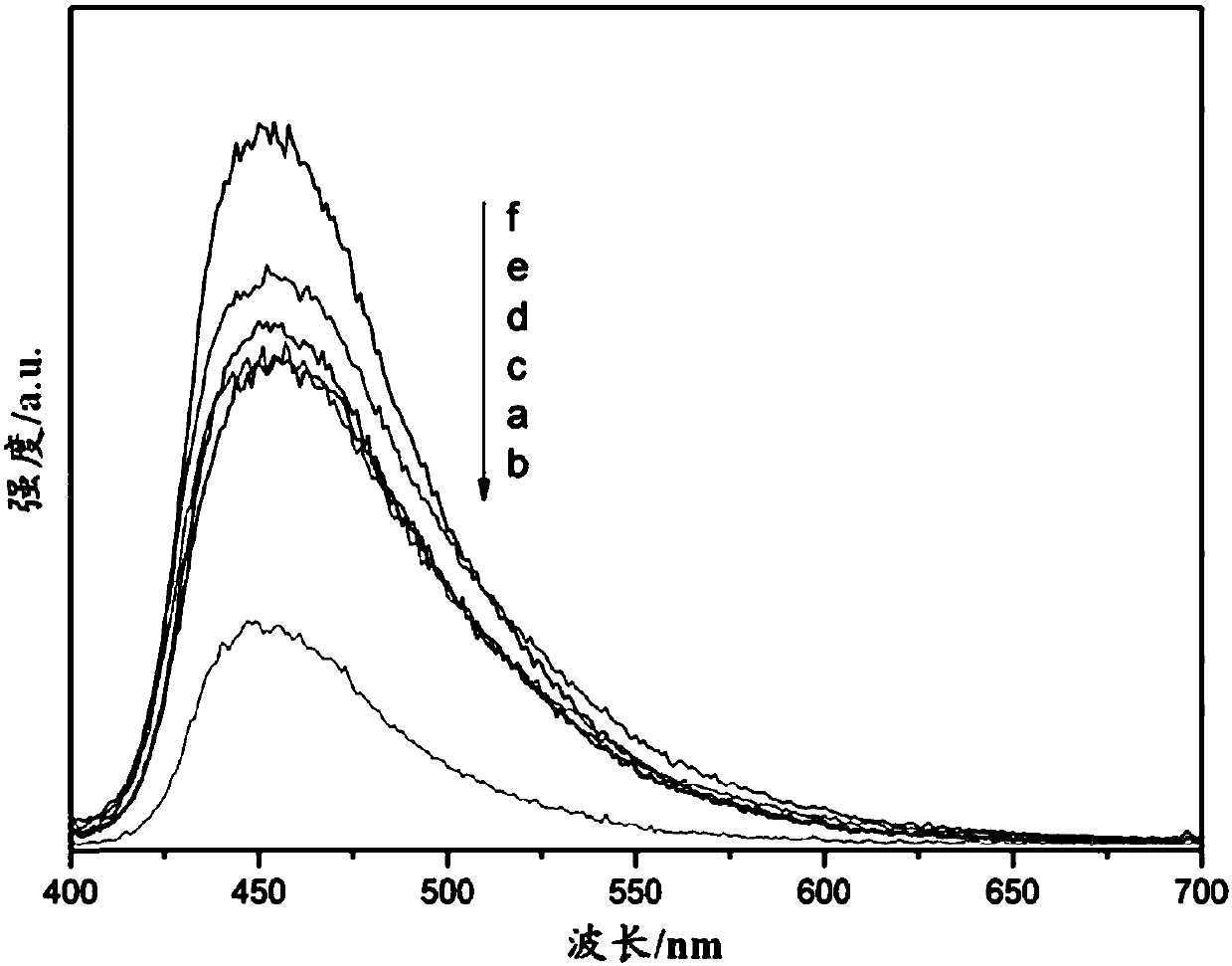

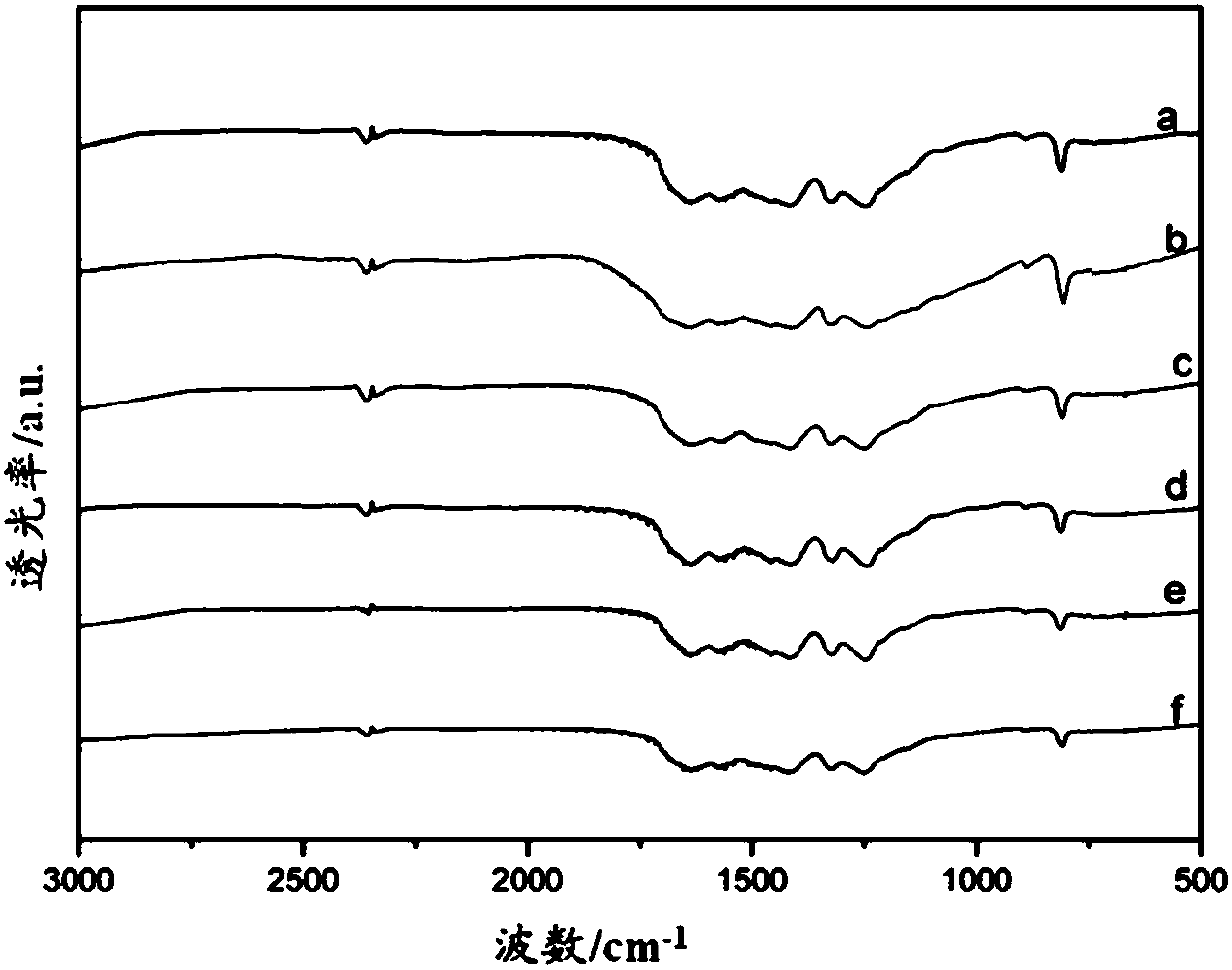

[0023] An acid modified g-C 3 N 4 The preparation method of the photocatalyst includes the following steps:

[0024] In step (1), the nitrogen-containing organic matter, distilled water and organic acid are put together in a reaction kettle, the temperature is raised to react, and the temperature is lowered after the reaction to obtain product I.

[0025] The inventors found that the use of low molecular weight nitrogen-containing organic matter with a carbon to nitrogen ratio of 1:3 to 3:1 as a raw material, preferably a small molecular weight nitrogen-containing organic matter with a carbon to nitrogen ratio of 1:2 as a raw material, After calcination in ℃ environment, gC with network structure can be obtained 3 N 4 , Such as cyanamide, dicyandiamine, melamine, urea, guanidine hydrochloride, etc., preferably melamine.

[0026] After research, it was found that g-C prepared by polycondensation of melamine 3 N 4 It contains a small amount of hydrogen, these hydrogens exist on the pri...

Embodiment 1

[0058] Accurately weigh 3.0 g of melamine and place it in the reactor, add 40 mL of distilled water and 10 mL of glacial acetic acid, then put it into an oven, set the temperature to 180°C, and after reacting for 12 hours, take out the reactor and cool it naturally to room temperature. The obtained product was suction filtered, washed with distilled water, and placed in an oven at 60°C for vacuum drying. Put the dried product into a closed porcelain crucible, heat it to 520℃ at a rate of 10℃ / min in a box-type resistance furnace, take it out after calcination for 4h and cool it to room temperature. Grind the resultant product. The catalyst sample is marked as HAc(10) / gC 3 N 4 , And finally put the product in the sample bag, sealed and stored.

Embodiment 2

[0060] Accurately weigh 3.0 g of melamine and place it in the reactor, add 40 mL of distilled water and 20 mL of glacial acetic acid, then put it in an oven, set the temperature to 180°C, and after reacting for 12 hours, take out the reactor and cool to room temperature. The obtained product was suction filtered, washed with distilled water, and placed in an oven at 60°C for vacuum drying. Put the dried product into a closed porcelain crucible, heat it to 520℃ at a rate of 10℃ / min in a box-type resistance furnace, take it out after calcination for 4h and cool it to room temperature. Grind the resultant product. The catalyst sample is marked as HAc(20) / gC 3 N 4 , And finally put the product in the sample bag, sealed and stored.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com