Driving structure based on spherical tire

A technology of spherical tires and driving structures, applied in the direction of wheels, motion deposition, power devices, etc., can solve the problems of high cost, high price, complicated replacement, etc., and achieve the effects of good vibration isolation performance, easy disassembly and maintenance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

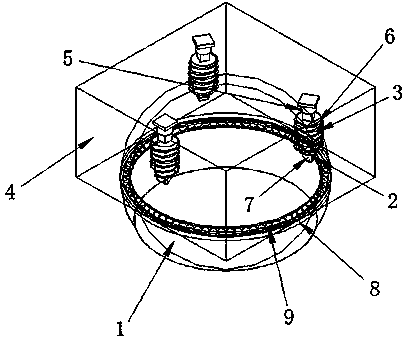

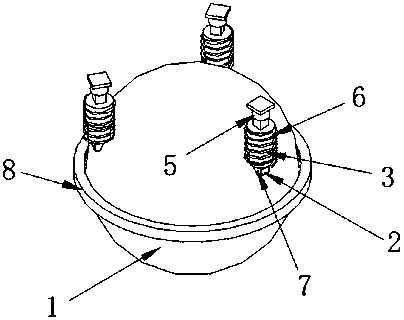

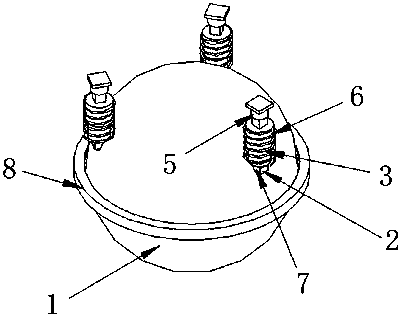

[0028] Such as Figure 1-5 As shown, the present invention provides a kind of driving structure based on spherical tire, comprises spherical tire 1, and the upper half of spherical tire 1 is provided with driving device 111, and driving device 111 comprises driving wheel 2 and driving motor 7, and the top of driving device 111 One end of the hydraulic support shaft 3 is connected, the outside of the hydraulic support shaft 3 is covered with a spring shock absorber 6, the other end of the hydraulic support shaft 3 is connected to the wire mesh shock absorber 5, and one end of the wire mesh shock absorber 5 Fixed on the upper surface of the outer casing 4, between the driving wheel 2 and the spherical tire 1, the friction force is used as the driving force, and the weight of the car body and the human body is fully utilized to increase the driving force (friction force), and evenly distributed three A driving wheel 2 is used to drive the spherical wheel, and the ball bearing 222...

Embodiment 2

[0036] as attached figure 1 As shown, it includes a spherical tire 1 and a driving device 111. The spherical tire 1 adopts an inner hollow structure to reduce the weight of the tire itself. The rubber protective layer outside the spherical tire 1 uses a material with a large friction coefficient, so that the driving wheel 2 and the spherical tire are enlarged. 1 friction, more effective tire control, spherical tire 1 external rubber protective layer, so under the action of gravity, the driving wheel 2 and spherical tire 1 can have a larger contact area, increase friction, more effective tire control .

[0037] Three driving devices 111 are evenly distributed on the outer shell 4 and the spherical tire 1 top, including the driving motor 7 and the driving wheel 2. Under the action of the body and the body's gravity, the driving wheel 2 and the spherical tire 1 outer rubber protection layer can be Large-area contact is realized, frictional force is increased, and the driving of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com