Method for reinforcing lignin fiber soil stabilizer roadbed

A lignin fiber and soil technology, applied in the field of geotechnical engineering, can solve the problems that cannot meet the requirements of complex engineering construction, complex engineering construction foundation, complex soil reinforcement problems, etc., and achieve good application prospects, good structural viscosity, good resistance Effects of corrosion and freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

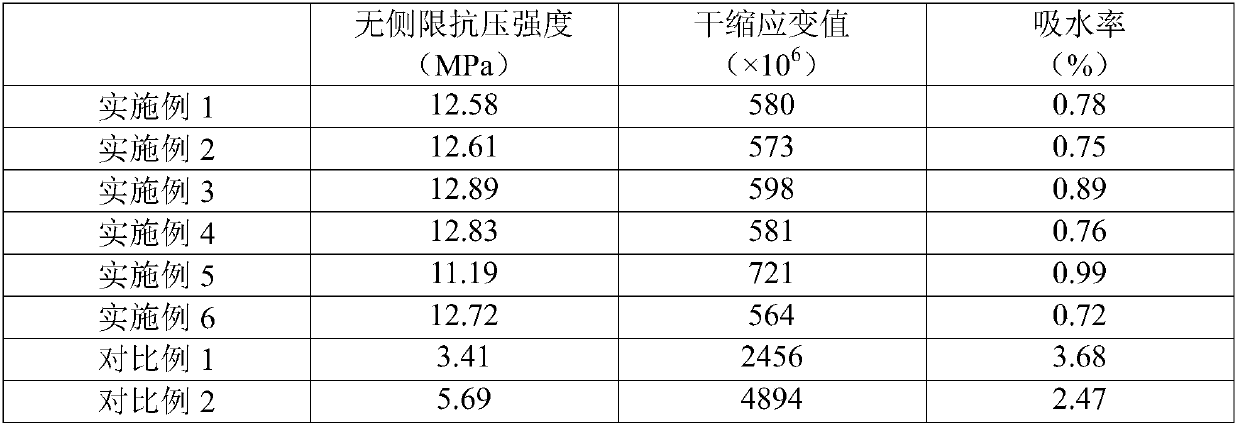

Embodiment 1

[0059] This example is used to illustrate the improved soil provided by the present invention and its preparation method.

[0060] Weigh 18g P.II 52.5 Portland cement, 37g slag, 10g lime, 8g gypsum, 12g water glass, 12g silica fume, 3g calcium chloride, 8g calcium sulfate, 5g triethanolamine and 2g polycarboxylate water reducer, It was placed in a stirrer and stirred at room temperature (25° C.) for 0.3 h to obtain a mixture.

[0061] Weigh 100g of soil material (dry weight, taken from the Bazhun heavy-duty railway area of Ordos City, Inner Mongolia, the same below), 6g of the above-mentioned mixture, 0.75g of lignin fiber and 87.4mL of water, and place them in a mixer at room temperature (25°C) Under stirring for 0.4h, improved soil T1 was obtained.

Embodiment 2

[0063] This example is used to illustrate the improved soil provided by the present invention and its preparation method.

[0064] Weigh 20g PO42.5 ordinary Portland cement, 40g slag, 12g lime, 10g gypsum, 15g water glass, 15g silica fume, 4g aluminum chloride, 10g sodium sulfate, 6g triethanolamine, 3g polycarboxylate superplasticizer, It was placed in a stirrer and stirred at room temperature (25° C.) for 0.3 h to obtain a mixture.

[0065] Weigh 100g of soil material (dry weight), 8g of the above mixture, 1g of lignin fiber and 87.4mL of water, put them in a mixer and stir at room temperature (25°C) for 0.4h to obtain improved soil T2.

Embodiment 3

[0067] This example is used to illustrate the improved soil provided by the present invention and its preparation method.

[0068] Weigh 15g P.II 52.5 Portland cement, 35g slag, 8g lime, 5g gypsum, 8g water glass, 10g silica fume, 2g calcium chloride, 5g calcium sulfate, 3g triethanolamine, 3g polycarboxylate superplasticizer, It was placed in a stirrer and stirred at room temperature (25° C.) for 0.3 h to obtain a mixture.

[0069] Weigh 100g of soil material (dry weight), 5g of the above mixture, 0.2g of lignin fiber and 87.4mL of water, put them in a mixer and stir at room temperature (25°C) for 0.4h to obtain improved soil T3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com