A kind of preparation method of early-strength polycarboxylate water reducer

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixture, can solve the problems of delayed concrete setting time, high synthesis cost, steel bar corrosion, etc., achieve early strength and outstanding water reducing effect, stable product quality, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

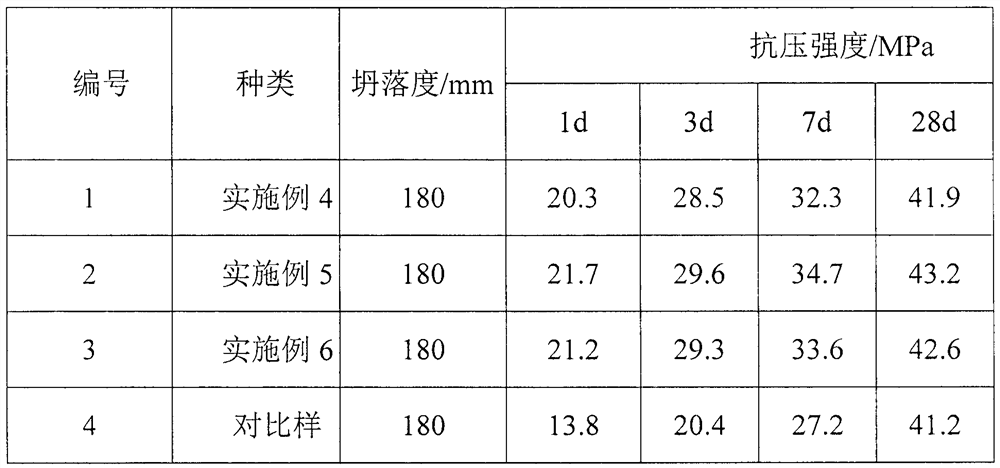

Examples

Embodiment 1

[0025] Embodiment 1: Esterification and amidation reaction of maleic anhydride

[0026] 3.9kg of maleic anhydride, 5kg of triethanolamine, 35g of polymerization inhibitor and 20kg of hydroxyl-terminated polyethylene glycol monomethyl ether with a molecular weight of 2000 were mixed evenly, under the catalytic action of 28g of p-toluenesulfonic acid, heated at 120 degrees Celsius The reaction was carried out for 1 hour; 6 kg of ground p-aminobenzenesulfonic acid was added, and the reaction was continued at 120 degrees Celsius for 0.5 hour to obtain a mixture I.

Embodiment 2

[0027] Embodiment 2: Esterification and amidation reaction of maleic anhydride

[0028] 12.5kg of maleic anhydride, 10kg of triethanolamine, 60g of polymerization inhibitor and 30kg of hydroxyl-terminated polyethylene glycol monomethyl ether with a molecular weight of 2000 were mixed evenly, under the catalytic action of 60g of p-toluenesulfonic acid, heated at 110 degrees Celsius The reaction was carried out for 2 hours; 7 kg of ground p-aminobenzenesulfonic acid was added, and the reaction was continued at 110 degrees Celsius for 1 hour to obtain a mixture I.

Embodiment 3

[0029] Embodiment 3: Esterification and amidation reaction of maleic anhydride

[0030]8.5kg of maleic anhydride, 7.5kg of triethanolamine, 50g of polymerization inhibitor and 25kg of hydroxyl-terminated polyethylene glycol monomethyl ether with a molecular weight of 2000 were mixed uniformly. 6.5 kg of ground p-aminobenzenesulfonic acid was added, and the reaction was continued at 115 degrees Celsius for 0.75 hours to obtain mixture I.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com