Permanent magnet direct-driven traction transmission system and method

A technology of traction transmission and permanent magnet direct drive, which is applied in electric traction, motor vehicles, electric vehicles, etc., can solve the problems of increased energy consumption, high electromagnetic noise, and large noise, and achieves reduced transmission loss, reduced electromagnetic radiation, and reduced Effect of motor noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

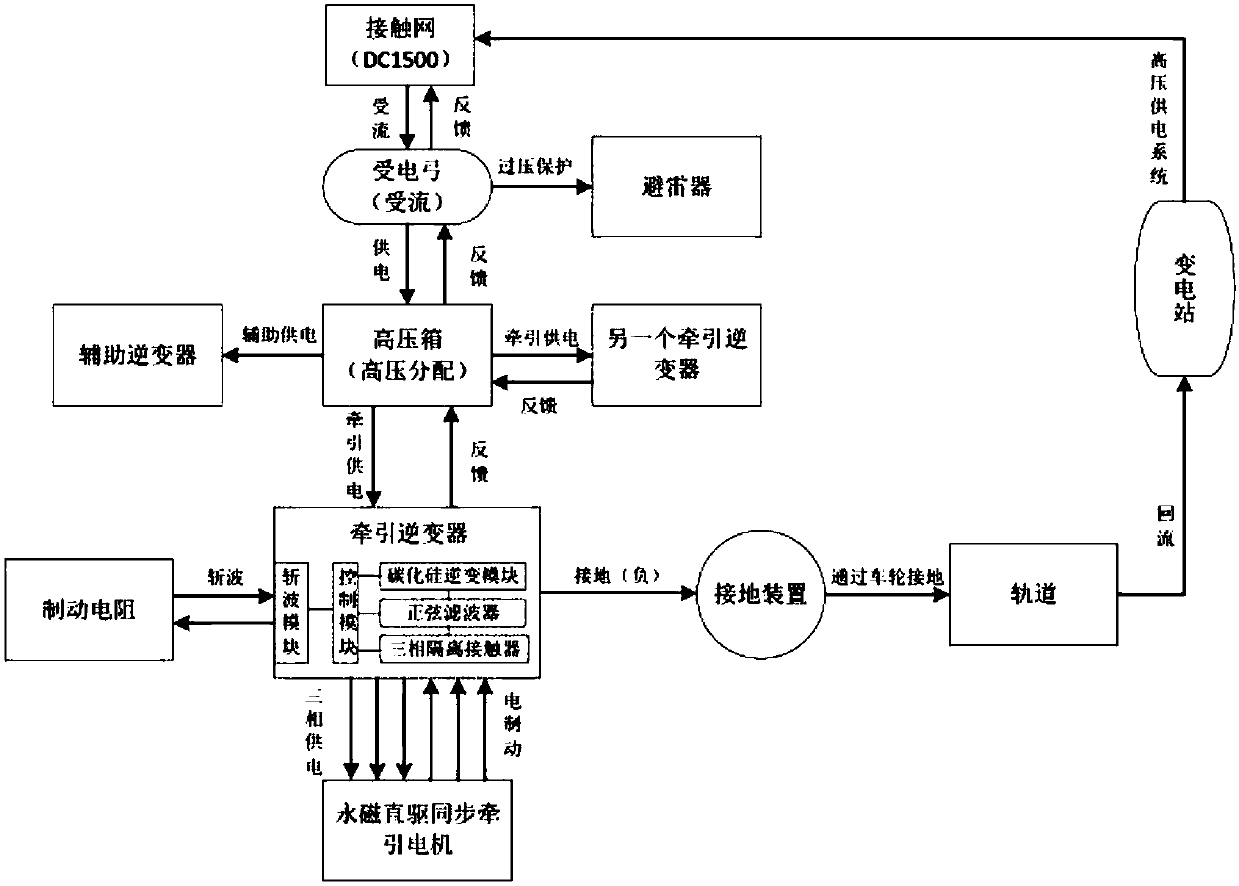

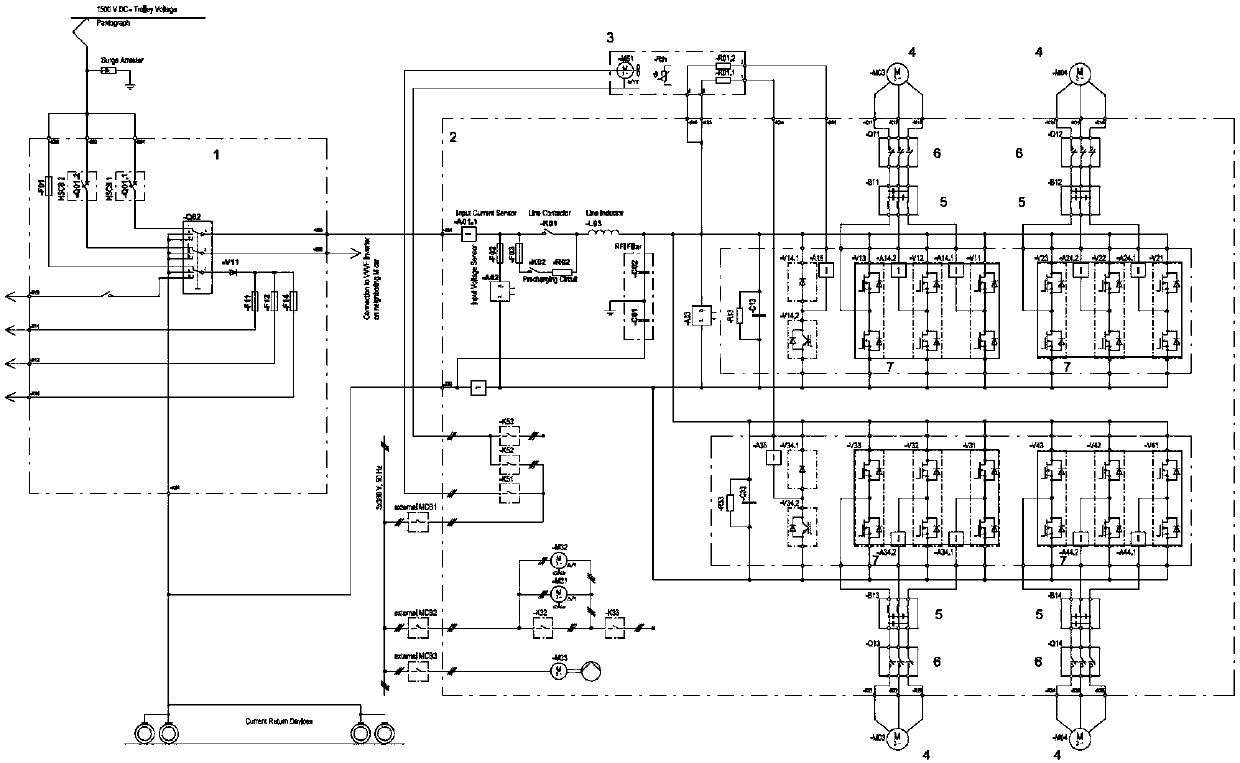

[0036] figure 2 It is a schematic circuit diagram of the present invention, and the names of the marked parts in the figure are: high voltage box 1, traction inverter 2, braking resistor 3, permanent magnet direct drive synchronous traction motor 4, sinusoidal filter 5, three-phase isolation contactor 6 , silicon carbide inverter module 7, figure 1 It is a connection block diagram of the present invention. It can be seen from the accompanying drawings that the permanent magnet direct drive traction transmission system is used to drive the motor car in the train, and the traction transmission system can drive two motor cars at the same time.

[0037] The traction drive system in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com