Three-level full-bridge soft switch current conversion circuit and control method therefor

A technology of full-bridge inverter circuit and control method, which is applied in the direction of adjusting electric variables, control/regulation systems, high-efficiency power electronic conversion, etc., and can solve problems such as reducing circuit reliability, individually controllable switching tubes, and increasing circuit complexity. , to achieve the effect of dynamic voltage clamping, simple and effective control method, and simplified design complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

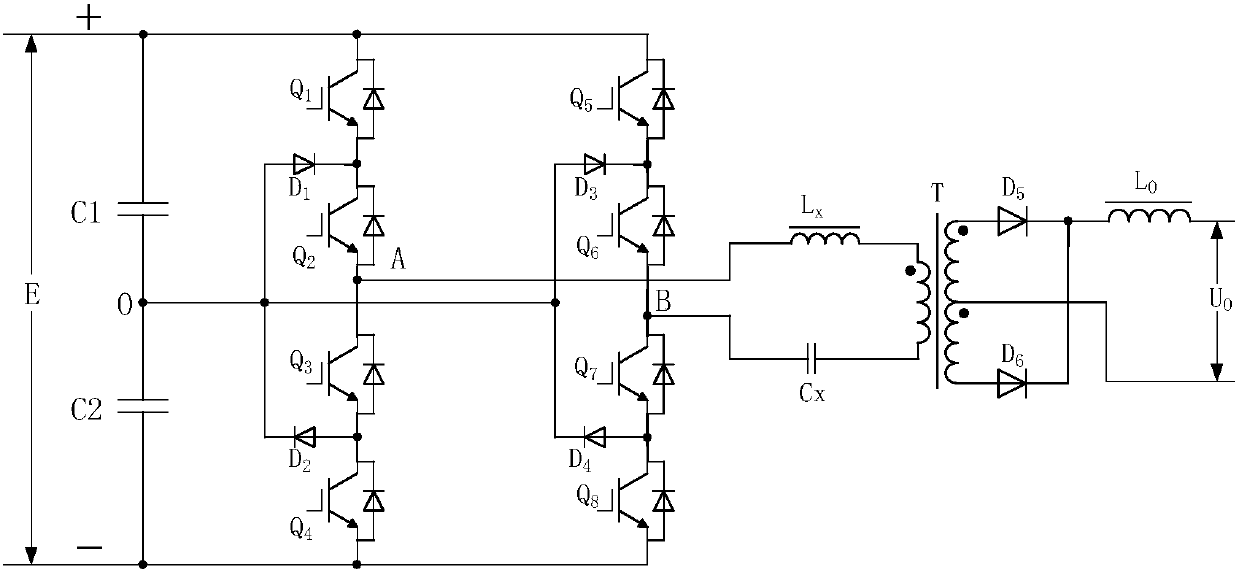

[0048] The invention discloses a three-level full-bridge soft-switching converter circuit, such as figure 1As shown, including: input voltage dividing capacitor, inverter circuit, saturated inductor, DC blocking capacitor, transformer and output circuit. The input voltage dividing capacitor is formed by connecting two capacitors C1 and C2 in series. The inverter circuit is composed of two three-level half-bridge arms, the switch tubes Q1~Q4 are connected in series in sequence, form a bridge arm with the clamping diodes D1, D2, the switch tubes Q5~Q8 are connected in series, and the clamping diodes D3, D4 Form another bridge arm. The connection points of the switch tubes Q1 and Q2 are connected to the cathode of the clamping diode D1, the connection points of the switch tubes Q3 and Q4 are connected to the anode of the clamping diode D2, the anode of the clamping diode D1 is connected to the cathode of D2, and the connection point is connected to the The midpoints of the volt...

Embodiment 2

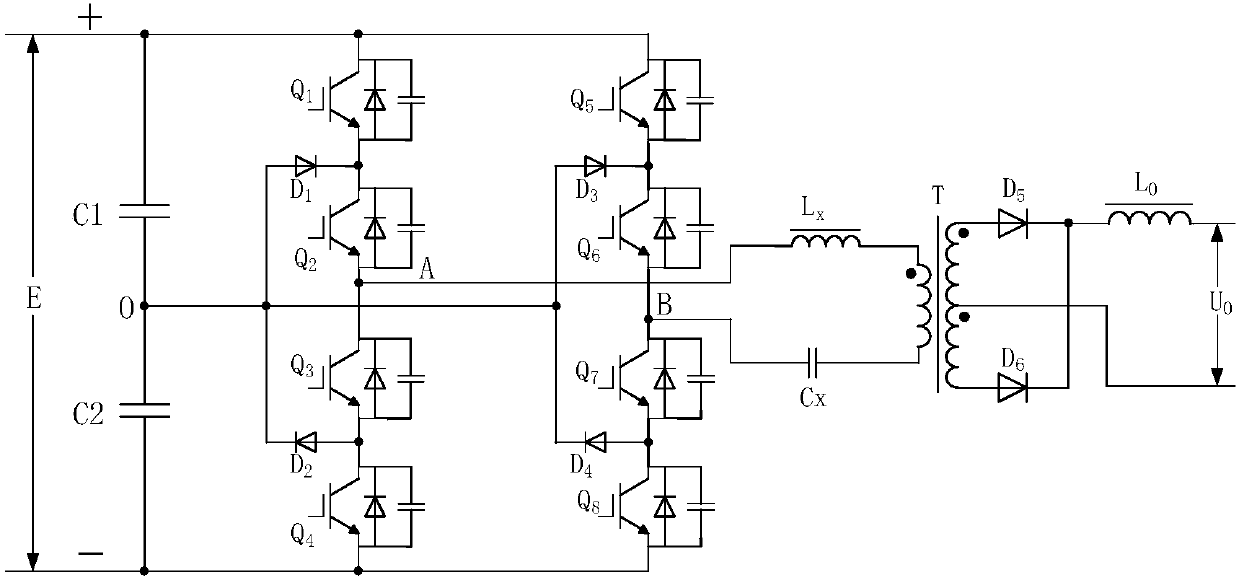

[0053] Such as figure 2 As shown, on the basis of the three-level full-bridge soft-switching converter circuit in Embodiment 1, capacitors are connected in parallel at both ends of each switching tube of the three-level bridge arm. However, after the capacitors are connected in parallel, an additional circuit needs to be added to ensure that the parallel capacitors will not be directly discharged through the switch tube under no-load or light-load conditions. Or it is applied in occasions where there is basically no no-load or light-load state, which limits the application environment of the converter circuit.

[0054] Other structures and working principles of the three-level full-bridge soft-switching converter circuit are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

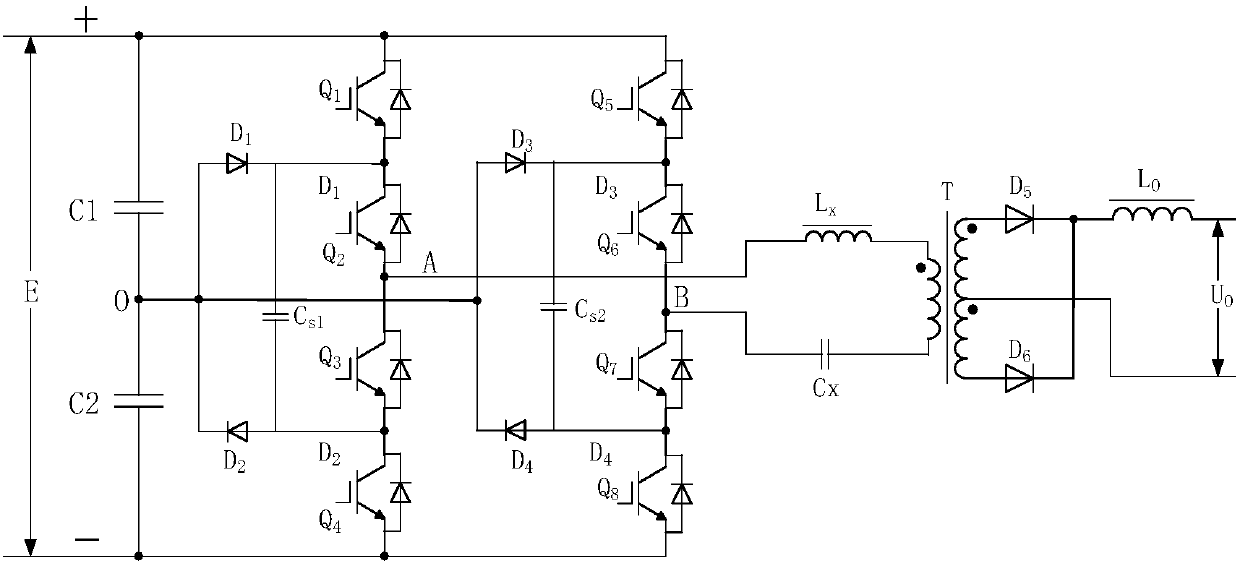

[0056] Such as image 3 As shown, on the basis of the three-level full-bridge soft-switching converter circuit of the first embodiment, after the clamping diodes D1 and D2 are connected in series, and after the diodes D3 and D4 are connected in series, the flying capacitors are connected in parallel at both ends thereof.

[0057] Other structures and working principles of the three-level full-bridge soft-switching converter circuit are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com