A frequency converter integrated braking system and its working method

A technology of braking system and working method, applied in control system, motor/generator/inverter limiter, motor-generator control, etc., can solve the problems of complex system, large energy consumption, complex structure of power unit, etc. Achieve the effect of simple system structure and guaranteed deceleration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

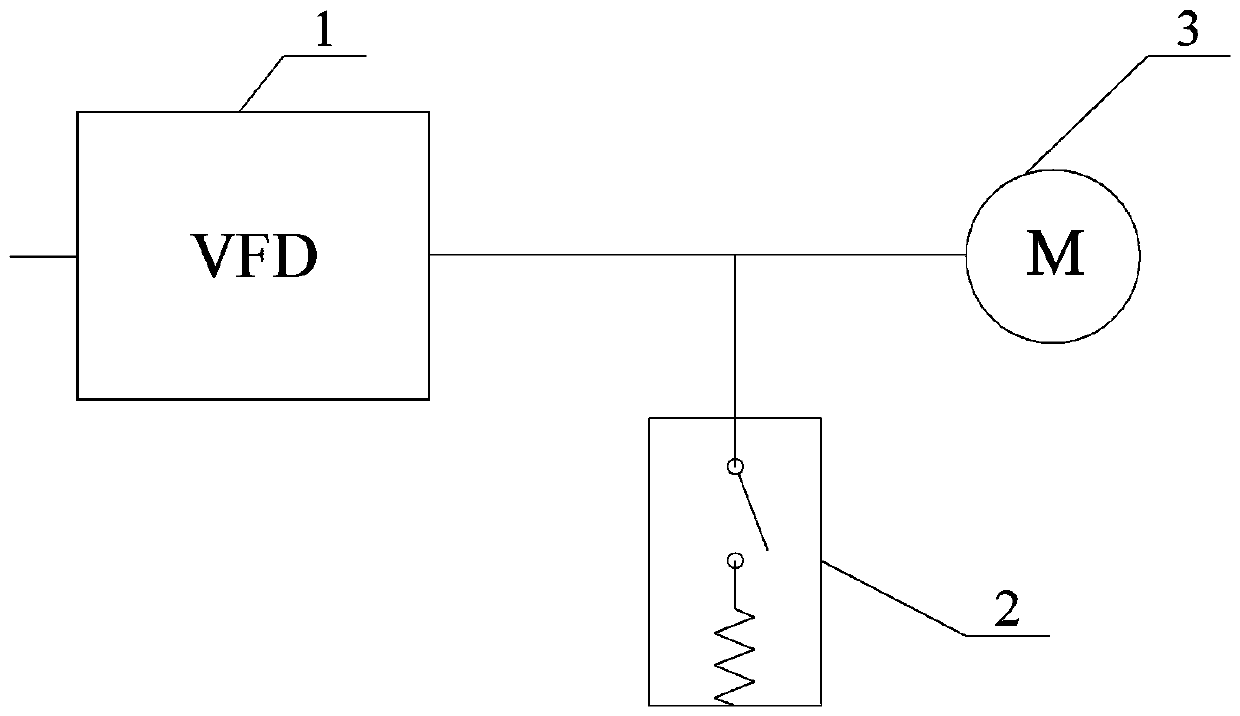

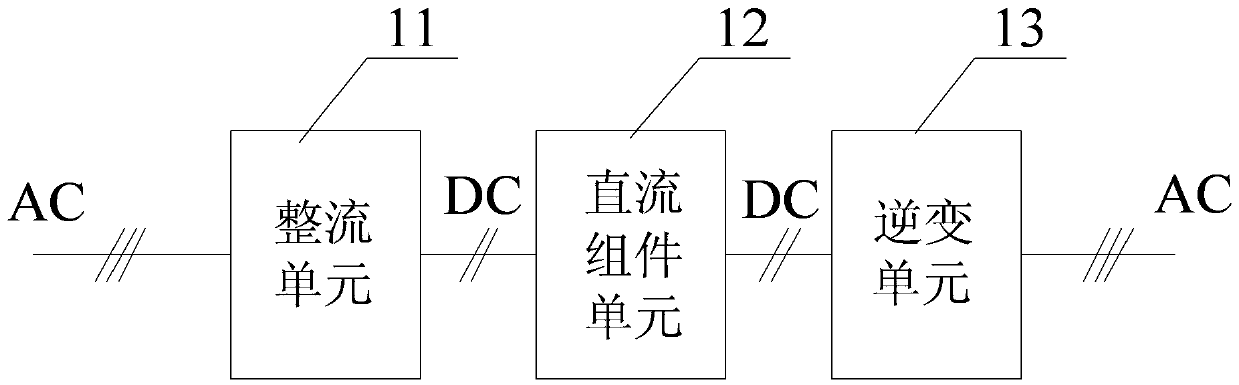

[0046] According to attached Figure 5 The rectification unit 11 of the frequency converter 1 of the present invention adopts a diode rectification unit, and the diode rectification unit includes 6 diodes. The DC component unit 12 includes a DC energy storage capacitor 121, a DC braking resistor 123, and a DC switch 122. The DC switch 122 is connected in series with the DC braking resistor 123 and then connected in parallel with the DC energy storage capacitor 121. The DC switch 122 is an electronic switch or a mechanical switch; the integrated braking system of the frequency converter has three working modes during the motor braking process: AC braking mode, comprehensive braking mode and variable frequency braking mode, when the integrated braking system of the frequency converter is in the variable frequency braking mode and comprehensive braking mode, the output current of the frequency converter 1 makes the output end of the frequency converter 1 absorb energy , the DC bu...

Embodiment 2

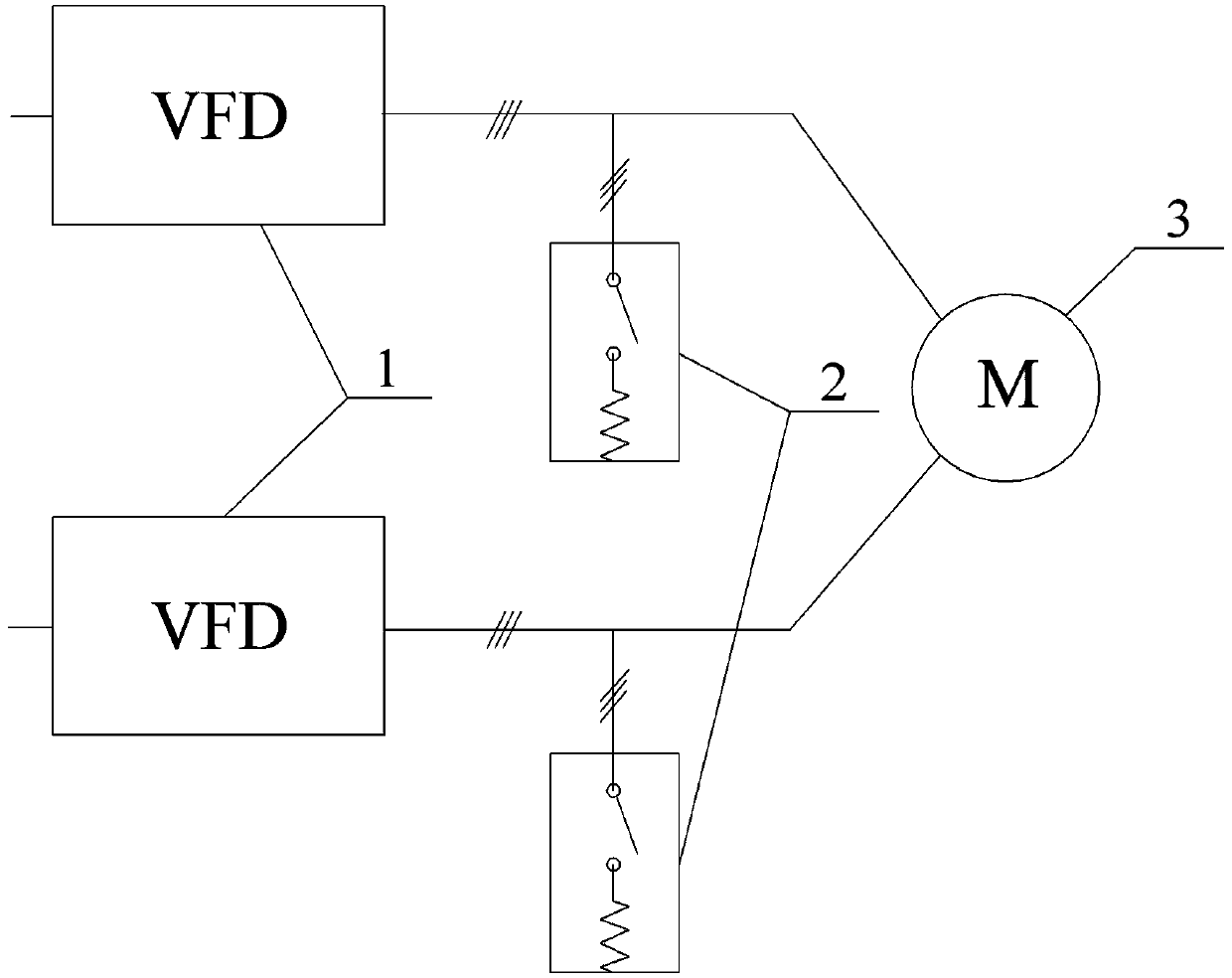

[0048] According to attached Figure 6 , the rectification unit 11 of the frequency converter 1 of the present invention adopts an active front-end rectification unit, and the active front-end rectification unit includes 6 IGBTs, and the DC component unit 12 includes a DC energy storage capacitor 121; There are three working modes in the braking process: AC braking mode, integrated braking mode and variable frequency braking mode. When the integrated braking system of the inverter is in the variable frequency braking mode and integrated braking mode, the inverter 1 outputs The current makes the output terminal of the inverter 1 absorb energy, the DC bus voltage of the inverter 1 is greater than the rectified voltage, the active front-end rectification unit is in the energy feedback mode, and converts the kinetic energy of the motor into electrical energy and feeds it back to the power grid. The inverter 1 Generate braking torque.

Embodiment 3

[0050] According to attached Figure 7 The rectification unit 11 of the frequency converter 1 of the present invention adopts a diode rectification unit, and the diode rectification unit includes 6 diodes, and the DC component unit 12 includes a DC energy storage capacitor 121 .

[0051] The integrated braking system of the frequency converter has three different situations during the motor braking process, which are:

[0052] The first type: The integrated braking system of the frequency converter has three working modes during the motor braking process: AC braking mode, integrated braking mode and variable frequency braking mode. mode and comprehensive braking mode, the output current of the inverter 1 makes the output end of the inverter 1 absorb energy, and the energy absorbed by the output end of the inverter 1 is balanced with the loss of the inverter 1 itself, so that the DC bus voltage of the inverter 1 is stable. This makes the diode in a cut-off state without causin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com