Method for machining titanium alloy hollow light-weight airfoil

A processing method and lightweight technology, applied in the direction of metal processing equipment, manufacturing tools, furnace types, etc., can solve the problems of difficult process, poor rigidity of welded parts, and difficult loading of tooling, so as to achieve low welding cost and high processing efficiency , Improve the effect of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Step 1, airfoil structure design,

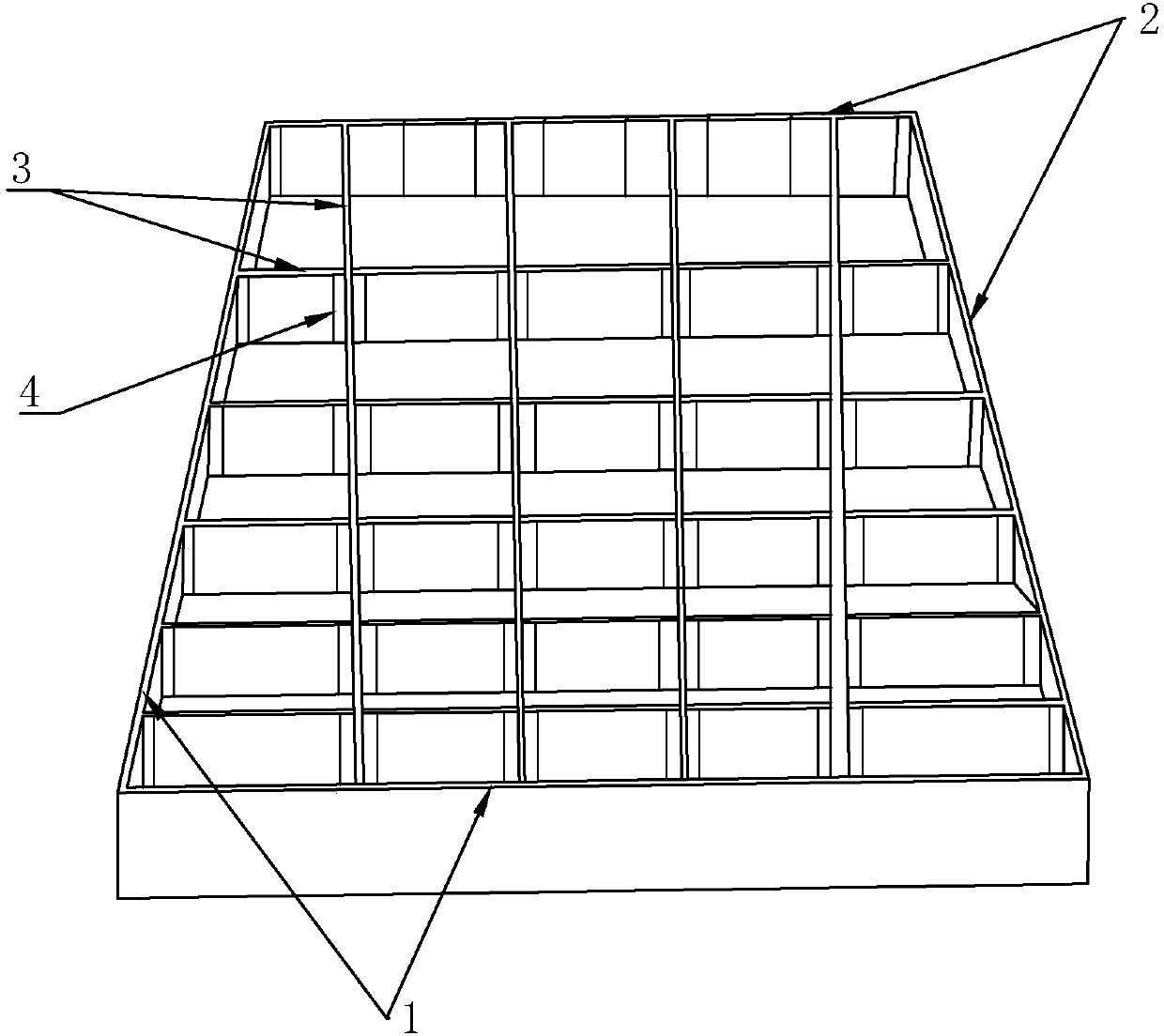

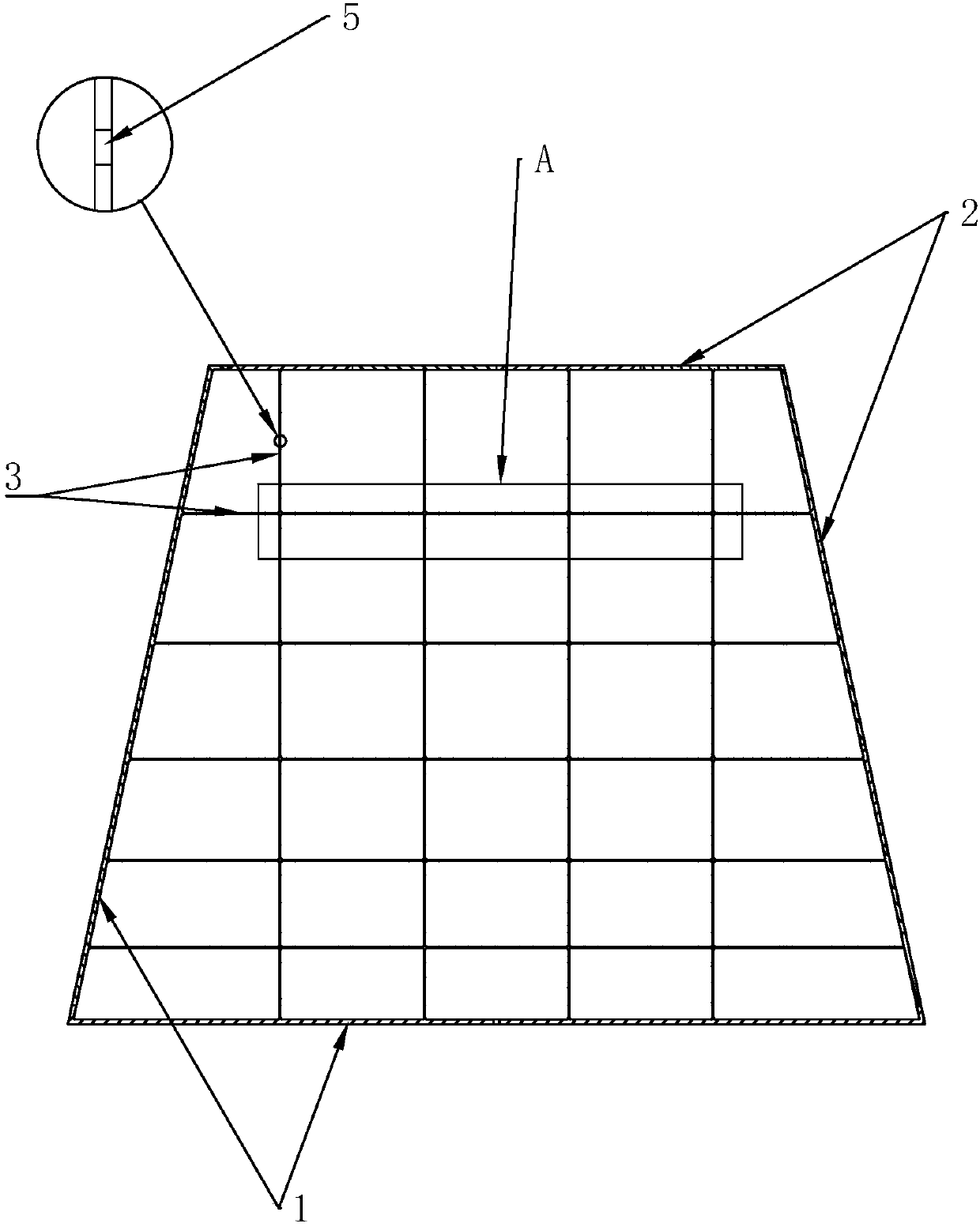

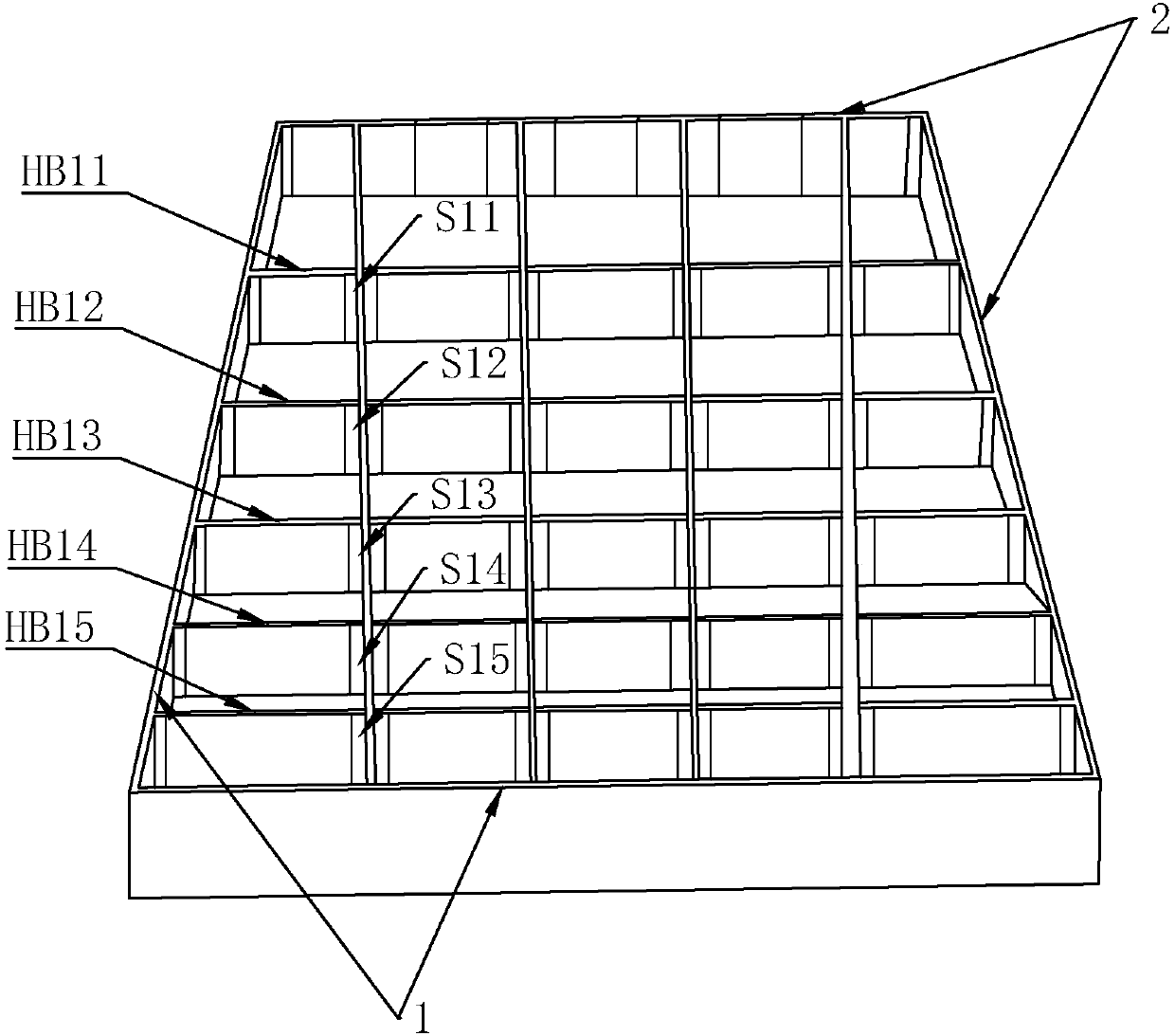

[0058] The airfoil includes skin, inner cell and frame, the thickness of the skin is 1.0mm, the thickness of the inner cell is 0.5mm, and the thickness of the frame is 3.0mm. The inner cell includes ribs 3 and connecting ribs 4. 4. Connect two intersecting ribs 3. The ribs 3 and the connecting ribs 4 form a truss structure. The skin is fixedly connected with the inner core and the frame. The frame includes the overall frame 1 and the split frame 2. The overall frame 1 is used for positioning , the split frame 2 is convenient for adjustment and installation;

[0059] The height of the rib plate 3 is 0.1mm higher than that of the connecting rib 4, and the rib plate 3 is provided with a ventilation hole 5;

[0060] Step two, prepare materials,

[0061] The skin, rib plate 3, connecting rib 4 and frame are cut to the design size, and pickled to remove skin impurities and oxide layers; among them, the rib plate 3 and skin are cut by lase...

Embodiment 2

[0072] Step 1, airfoil structure design,

[0073] The airfoil includes skin, inner cell and frame, the thickness of the skin is 1.0mm, the thickness of the inner cell is 1.2mm, and the thickness of the frame is 2.5mm. The inner cell includes ribs 3 and connecting ribs 4. 4. Connect two intersecting ribs 3. The ribs 3 and the connecting ribs 4 form a truss structure. The skin is fixedly connected with the inner core and the frame. The frame includes the overall frame 1 and the split frame 2. The overall frame 1 is used for positioning , the split frame 2 is convenient for adjustment and installation;

[0074] The height of the rib plate 3 is 0.2mm higher than that of the connecting rib 4, and the rib plate 3 is provided with a ventilation hole 5;

[0075] Step two, prepare materials,

[0076] The skin, rib plate 3, connecting rib 4 and frame are cut to the design size, and pickled to remove skin impurities and oxide layers; among them, the rib plate 3 and skin are cut by lase...

Embodiment 3

[0087] Step 1, airfoil structure design,

[0088] The airfoil includes skin, inner cell and frame, the thickness of the skin is 1.0mm, the thickness of the inner cell is 2.0mm, and the thickness of the frame is 2.0mm. The inner cell includes ribs 3 and connecting ribs 4. 4. Connect two intersecting ribs 3. The ribs 3 and the connecting ribs 4 form a truss structure. The skin is fixedly connected with the inner core and the frame. The frame includes the overall frame 1 and the split frame 2. The overall frame 1 is used for positioning , the split frame 2 is convenient for adjustment and installation;

[0089] The height of the rib plate 3 is 0.3mm higher than that of the connecting rib 4, and the rib plate 3 is provided with a ventilation hole 5;

[0090] Step two, prepare materials,

[0091] The skin, rib plate 3, connecting rib 4 and frame are cut to the design size, and pickled to remove skin impurities and oxide layers; among them, the rib plate 3 and skin are cut by lase...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com