Ceramsite manufacturing system

A technology of ceramsite and microwave suppression, which is applied to ceramic products, manufacturing tools, clay products, etc., can solve the problems of high energy consumption, and achieve the effect of simple structure, high reliability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

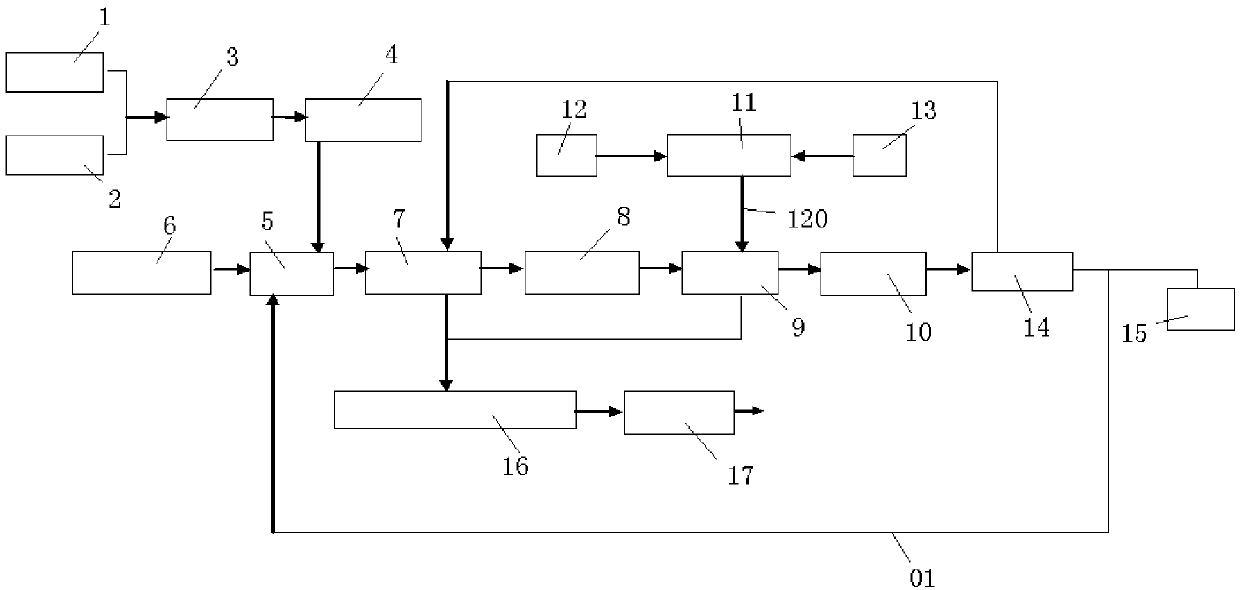

[0050] Such as figure 1 As shown, the ceramsite production system includes fly ash storage equipment 1, water storage equipment 2, ball forming equipment 3, material distribution equipment 4, conveying components, propulsion equipment 6, preheating equipment 7, microwave heating device, electric control equipment 12. Water cooling equipment 13, cooler 14, crushing and screening equipment 15, denitrification, desulfurization and dust removal device 16, induced draft fan 17 and hollow device. Among them, the conveying components include kiln car and running track, wherein the running track includes loading track and unloading track, microwave heating device includes feeding microwave suppressor 8, microwave sintering furnace 9, discharging microwave suppressor 10, microwave energy feeding equipment 11 and microwave guide 120. The specific connection relationship is as figure 1 shown.

[0051] The working process of the production system includes:

[0052] The coarse ash in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com