Volumetric type automatic quantitative packing machine and capacity regulating device thereof

A technology of capacity adjustment and packaging machine, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of high labor intensity of employees, reduced trust of substrate fertilizer manufacturers, and increased cost of seedling cultivation, so as to reduce removal and storage capacity. The effect of occupying pressure, reducing the labor intensity of employees, and high quantitative uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

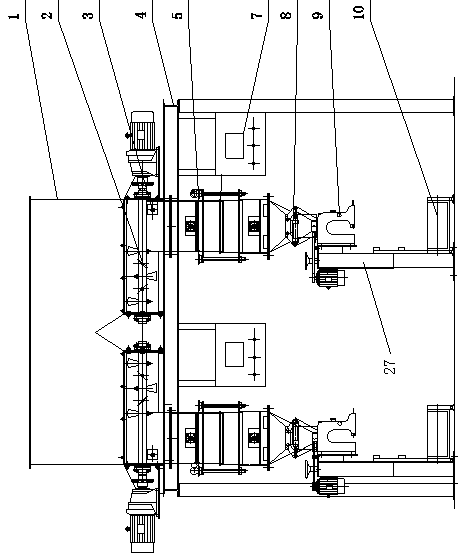

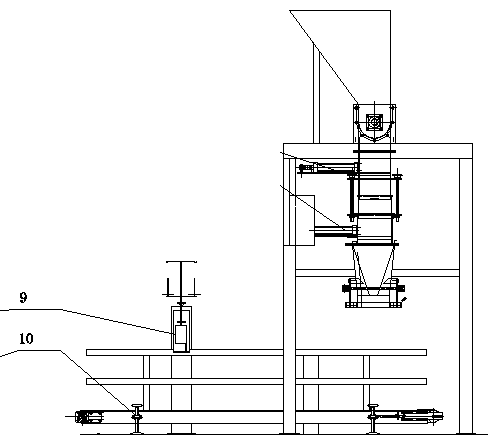

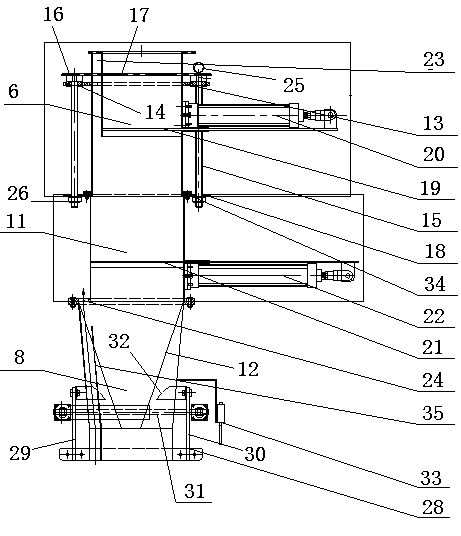

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

[0020] The capacity adjusting device for packaging machine of the present invention comprises an upper volume body 6 and a lower volume body 11 which are nested with each other, the upper part of the upper volume body is provided with a feed inlet, and the lower part of the lower volume body is provided with a discharge nozzle 12; An upper flange 13 is fixed on the outside, and several bearings 14 are fixed on the upper flange. A vertical screw 15 is embedded in each bearing, and a sprocket 16 is fixed on the upper end of each screw. They are synchronously connected by a chain 17, one of which has an adjustment device at the upper end of the screw; the outer side of the lower volume body is fixed with a lower flange 18, and the lower flange is provided with several holes, each hole is welded with a fixing nut 26, the screw The lower end is screwed into each fixing nut on the lower flange, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com