Magnesium cement with high water resistance and preparation method thereof

A magnesium cement, water-based technology, applied in the field of high water-resistant magnesium cement and its preparation, can solve the problems of low water resistance of cement, achieve the effects of improving water resistance, compact structure, and reducing supersaturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

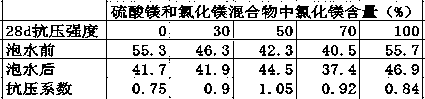

Embodiment 1

[0023] A high water-resistance magnesium cement is characterized in that it is made of the following raw materials: light-burned magnesia powder, magnesium sulfate and magnesium chloride mixture, water, potassium dihydrogen phosphate, the light-burned magnesia powder, magnesium sulfate and The mass ratio of magnesium chloride mixture to water is 14.5:1:22, wherein the mass ratio of magnesium chloride to the mixture is 0, the content of active magnesium oxide in the light-burned magnesium oxide powder is 60%, potassium dihydrogen phosphate The content is 0.5% of the mass of light-burned magnesia powder.

[0024] The preparation method of described high water resistance cement comprises the following steps:

[0025] S1: raw material weighing;

[0026] S2: weighing each raw material according to the quality of the raw material;

[0027] S3: dissolving the magnesium sulfate and magnesium chloride mixture in water;

[0028] S4: Incorporation of potassium dihydrogen phosphate;

...

Embodiment 2

[0035] A high water-resistant magnesium cement is characterized in that it is made of the following raw materials: light-burned magnesia powder, a mixture of magnesium sulfate and magnesium chloride, water, the light-burned magnesia powder, a mixture of magnesium sulfate and magnesium chloride, water, The substance ratio of potassium dihydrogen phosphate is: 14.5:1:22, wherein magnesium chloride accounts for 30% of the substance ratio of the mixture, the content of active magnesium oxide in the light-burned magnesium oxide powder is 60%, dihydrogen phosphate The content of potassium is 0.5% of the mass of light-burned magnesia powder.

[0036] The preparation method of described high water resistance cement comprises the following steps:

[0037] S1: raw material weighing;

[0038] S2: weighing each raw material according to the quality of the raw material;

[0039] S3: dissolving the magnesium sulfate and magnesium chloride mixture in water;

[0040] S4: Incorporation of p...

Embodiment 3

[0047] A high water-resistance magnesium cement is characterized in that it is made of the following raw materials: light-burned magnesia powder, magnesium sulfate and magnesium chloride mixture, water, potassium dihydrogen phosphate, the light-burned magnesia powder, magnesium sulfate and The mass ratio of the magnesium chloride mixture to water is 14.5:1:22, wherein magnesium chloride accounts for 50% of the mass of the mixture, the content of active magnesium oxide in the light-burned magnesium oxide powder is 60%, dihydrogen phosphate The content of potassium is 0.5% of the mass of light-burned magnesia powder.

[0048] The preparation method of described high water resistance cement comprises the following steps:

[0049] S1: raw material weighing;

[0050] S2: weighing each raw material according to the quality of the raw material;

[0051] S3: dissolving the magnesium sulfate and magnesium chloride mixture in water;

[0052] S4: Incorporation of potassium dihydrogen ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com