Polyether modified organic silicon defoamer and preparation method thereof

A silicone defoamer, polyether modification technology, applied in separation methods, chemical instruments and methods, foam dispersion/prevention, etc., can solve problems such as difficult balance, achieve less steps, anti-foaming performance and compatibility The effect of sexual optimization and improvement, operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A preparation method of polyether modified silicone defoamer (reaction flow shown in reaction formula I), comprising:

[0041] One reaction step: mix polyether-modified silicone B (structural formula IV) with tetramethyldihydrodisiloxane (hydrogen-containing double head, structural formula VI), add a strong acid solution, react at room temperature for 6-10 hours, and Equilibrium reaction obtains the first reaction product (structural formula VII);

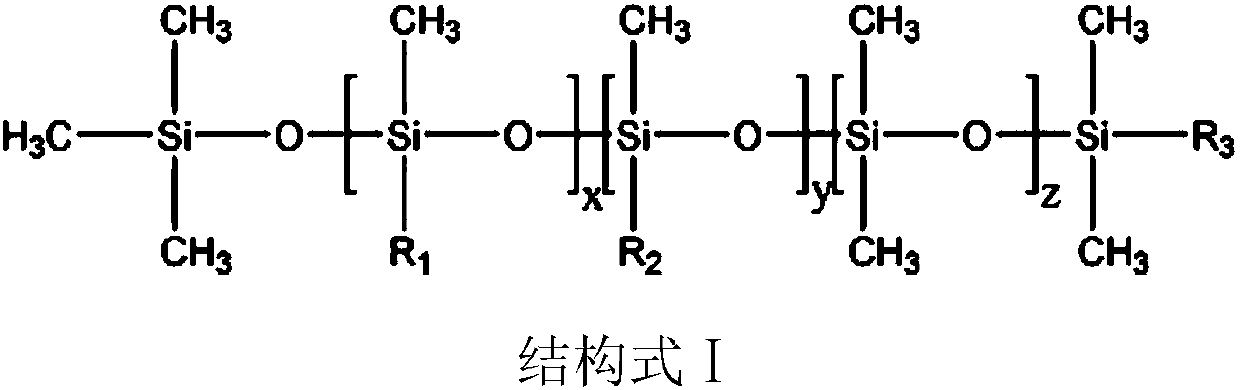

[0042] Secondary reaction step: mix the first reaction product with linear α-olefin (structural formula V), add catalyst, react at 20-80°C for 2-6h, and obtain polyether-modified organic compound after addition reaction Defoamer for Silicon A (Formula I).

[0043]

[0044] As a further embodiment, in one reaction step, polyether modified silicone B is a commercially available polyether modified silicone product, for example selected from Momentive Silwet DA-33, Silwet DA-63, Silwet DA-40, Silwet SPM-2, Silwet SPM-1, Sil...

Embodiment 1

[0053] A preparation method of polyether modified silicone defoamer (reaction flow shown in reaction formula I), comprising:

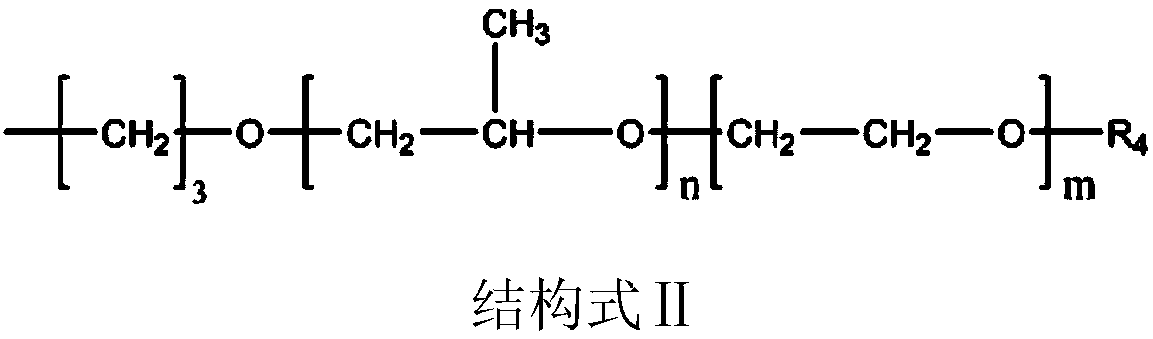

[0054] One reaction step: use commercially available polyether-modified silicone B (structural formula IV) and hydrogen-containing double head (tetramethyldihydrodisiloxane, structural formula VI) in a ratio of 1:1 at 98% concentration Under the condition of sulfuric acid, react at normal temperature for 8h to obtain the first reaction product (structural formula VII); in the first reaction product, z=20, x=y=2, R 1 , R 2 The polyether structure is the same (structural formula II), where m=n=12, R 4 is a hydrogen group;

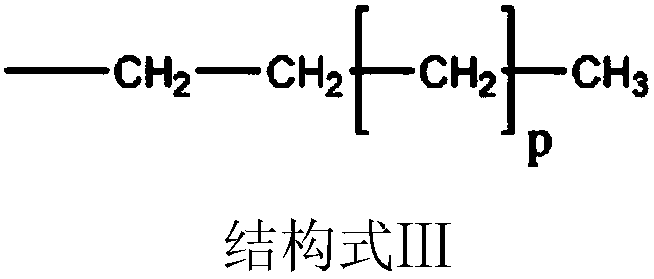

[0055] Secondary reaction step: first reaction product and linear α-olefin (CH 2 =CH(CH 2 ) p CH 3 , p=13) reaction, the reaction conditions are: chloroplatinic acid as catalyst, 40-60 ℃, react for 4h, finally obtain the defoamer containing polyether modified silicone A (structural formula I), in the structural formula I, z =20...

Embodiment 2

[0057] A preparation method of polyether modified silicone defoamer (reaction flow shown in reaction formula I), comprising:

[0058] One reaction step: use commercially available polyether-modified silicone B (structural formula IV) and hydrogen-containing double head (tetramethyldihydrodisiloxane, structural formula VI) in a ratio of 1:1 at 98% concentration Under the condition of sulfuric acid, react at normal temperature for 8h to obtain the first reaction product (structural formula VII); in the first reaction product, x=2, y=6, z=40, R 1 , R 2 For different polyether structures (structural formula Ⅱ), in R 1 m=0, n=24, R 4 is methyl; in R 2 where m=10, n=0, R 4 is methyl;

[0059] Secondary reaction step: first reaction product and linear α-olefin (CH 2 =CH(CH 2 ) p CH 3 , p=9) reaction, the reaction conditions are: chloroplatinic acid as catalyst, 40-60 ℃, react for 4h, finally obtain the defoamer containing polyether modified silicone A (structural formula I),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com