Gd doped Li7La3Zr2O12 johnstonotite type solid electrolyte for all-solid-state lithium ion battery

A lithium-ion battery, solid electrolyte technology, used in secondary batteries, circuits, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

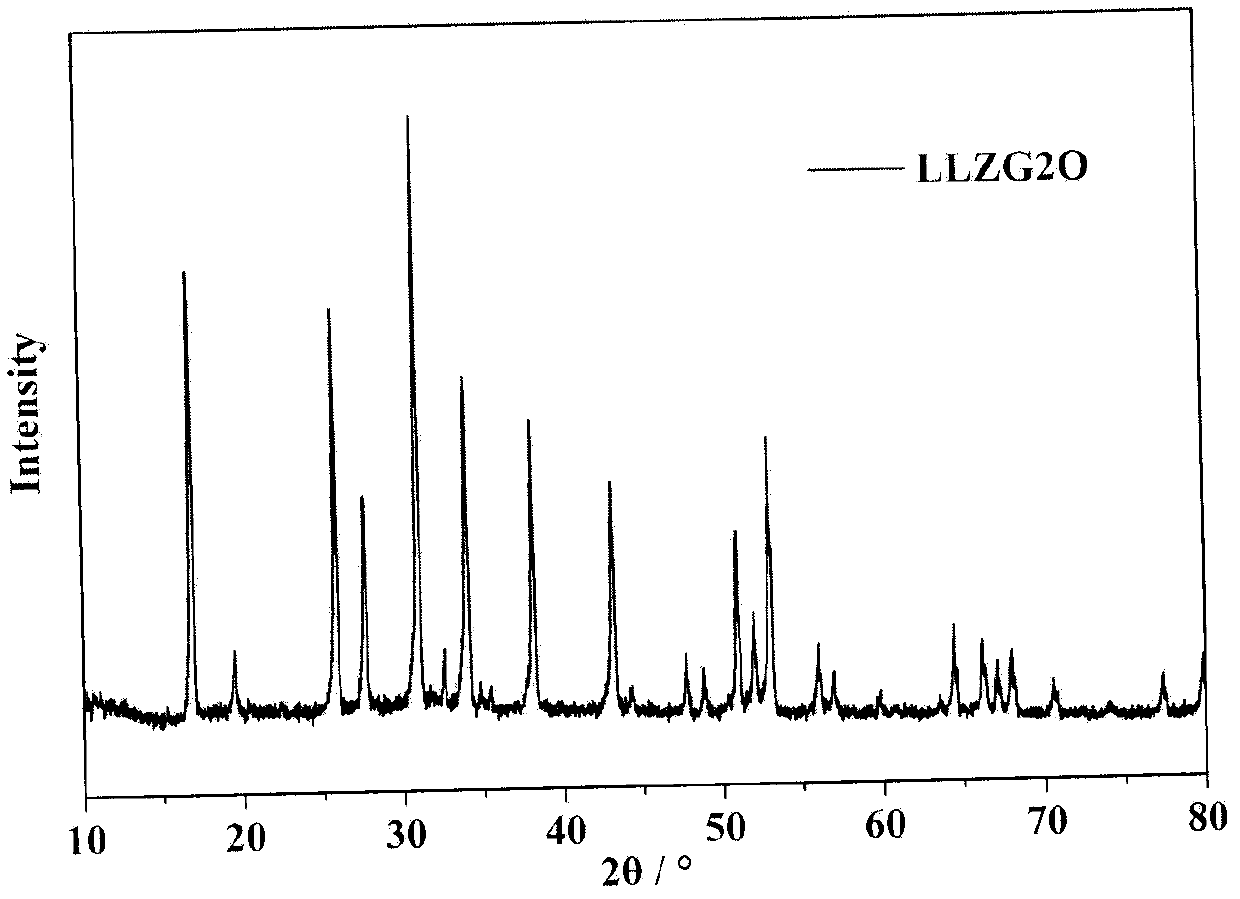

[0020] According to Li 7.2 La 3 Zr 1.8 Gd 0.2 o 12 The stoichiometric ratio of each content in (LLZG2O) weighs Li 2 CO 3 (or LiOH), La(OH) 3 (or La 2 o 3 ), ZrO 2 and Gd 2 o 3 The analytically pure reagent is placed in a ball mill jar, and isopropanol is used as a solvent, wherein the weight ratio "raw material: ball: isopropanol" is 1-2:1-3:1-2. Put it on a ball mill for 24 hours, then dry it in an oven at 80°C and place it in a muffle furnace for calcination at 850°C to 1000°C for 20 to 30 hours, then press it into tablets, and finally put the pressed tablets in Calcined at 1100-1250°C for 24-48 hours in a muffle furnace, the X-ray diffraction (XRD) pattern of the prepared solid electrolyte sheet is shown in figure 1 .

Embodiment 2

[0022] According to Li 7.2 La 3 Zr 1.8 Gd 0.2 o 12 The stoichiometric ratio of each content in (LLZG2O) weighs Li 2 CO 3 (or LiOH), La(OH)3 (or La 2 o 3 ), ZrO 2 and Gd 2 o 3 The analytically pure reagent is placed in a ball mill jar, and isopropanol is used as a solvent, wherein the weight ratio "raw material: ball: isopropanol" is 1-2:1-3:1-2. Put it on a ball mill for 24 hours, then dry it in an oven at 80°C and place it in a muffle furnace for calcination at 850°C to 1000°C for 20 to 30 hours, then press it into tablets, and finally put the pressed tablets in Gd-doped Li 7 La 3 Zr 2 o 12 Solid Electrolyte Sheet. The prepared solid electrolyte sheets were polished on 400-mesh and 800-mesh sandpaper respectively, using isopropanol as a solvent for wet grinding. Afterwards, the polished solid electrolyte sheet was cleaned with isopropanol and ultrasonically cleaned in a beaker filled with isopropanol for half an hour, then taken out and placed in an oven for d...

Embodiment 3

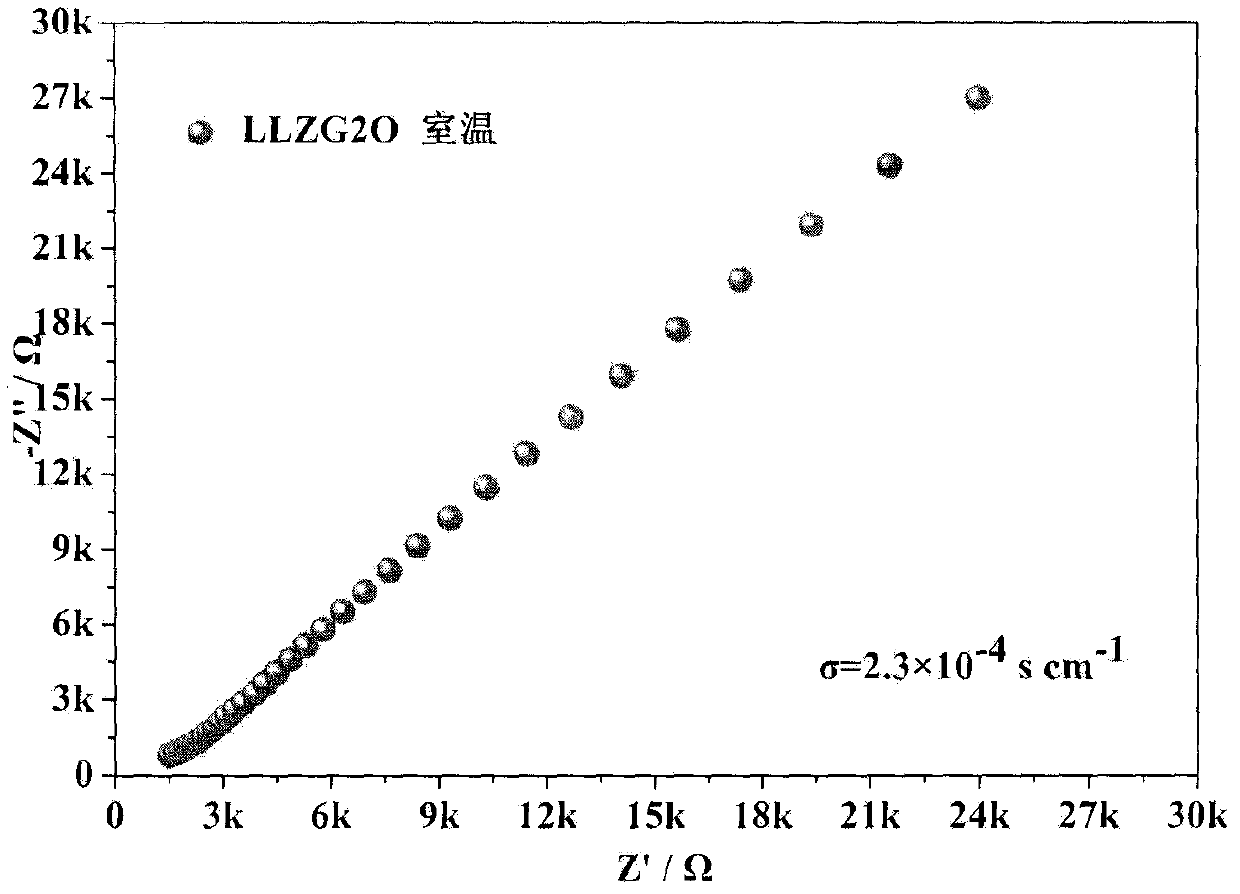

[0024] Doping the prepared Gd with Li 7 La 3 Zr 2 o 12 The solid electrolyte sheet is polished to a thickness of 0.3-1mm, and the AC impedance measurement is performed on the polished solid electrolyte sheet. The specific steps are: first coat the silver paste on one side of the solid electrolyte sheet as an electrode, and connect it to the silver wire, then place it in an oven at 100-150°C for drying, and then apply the silver paste on the solid electrolyte sheet in the same way. The other side of the electrolyte sheet is also connected to the silver wire, and then it is sintered in a muffle furnace at 300-600°C for 2-5 hours, and then the AC impedance of the solid electrolyte sheet is measured, as shown in image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com