Short-process nitrification cooperated As(III) oxidization method

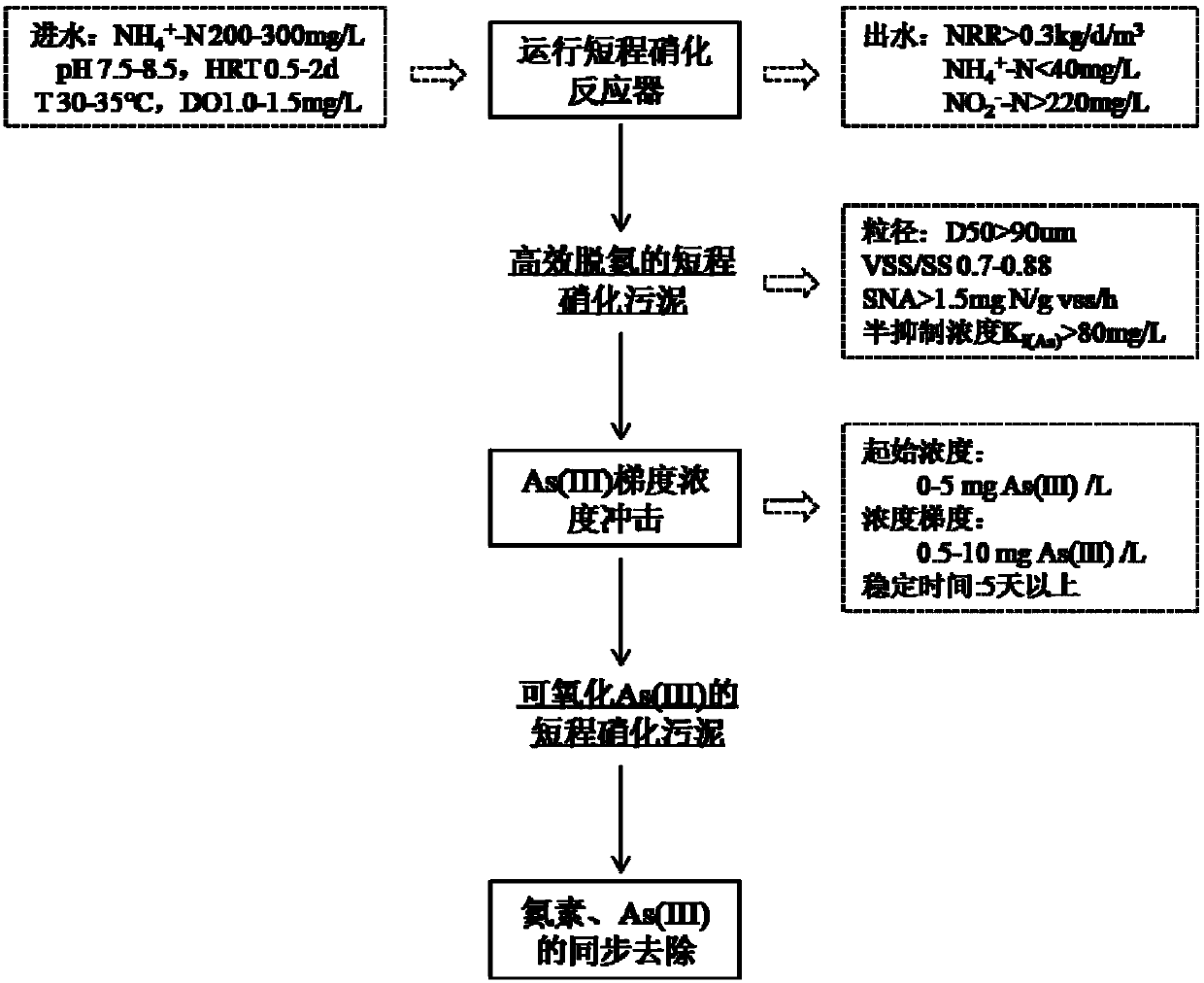

A short-range nitrification and synergistic oxidation technology, applied in the field of environmental engineering, can solve the problems of slow direct oxidation, high cost, easy introduction of impurities, etc., achieve the effect of ammonia oxidation and arsenic detoxification, and reduce the cost of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A laboratory-scale (volume 5L) SHARON reactor was used to cultivate short-path nitrification sludge with high-efficiency denitrification. The strategy is as follows: Control matrix NH in influent simulated wastewater 4 + -N concentration is at a higher level, and the hydraulic retention time (HRT) is gradually shortened to increase the volume load of the short-path nitrification reactor. Ultimate: Influent NH 4 + -N concentration increased from 200mg / L to 300mg / L, HRT shortened from 2d to 0.5d, volumetric nitrogen load from 0.3kg / m 3 / d increased to 0.48kg / m 3 / d. In order to obtain short-range nitrification sludge with high efficiency denitrification, its specific physical and chemical characteristics include: SNA reaches 1.57mg N / g VSS / h, sludge particle size (D50) is higher than 90um, VSS is 3.792g / L, VSS / SS is 0.7-0.88, pH 7.5-8.5, temperature 30-35°C.

Embodiment 2

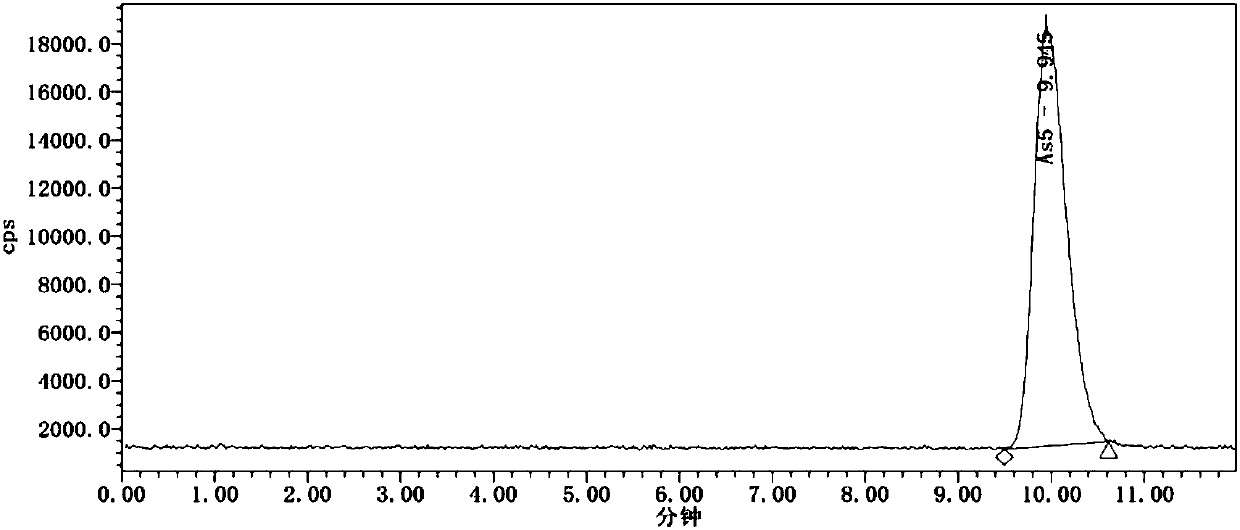

[0027]In this example, according to the strategy of Example 1, short-range nitrification sludge with high efficiency denitrification is cultivated, and at the same time, NaAsO 2 Prepare 250mL solution containing As(III) with a concentration of 5mg / L, as the reaction substrate water of the short-range nitrification system, the flocculent sludge concentration VSS is 3.792g / L, and the NH 4 + -N concentration is 300mg / L, adjust pH with NaOH solution, control pH at 7.5-8.5, measure DO with dissolved oxygen analyzer, control it at 1.0-1.5, and control temperature at 30-35°C. The reaction was carried out for 8 hours under magnetic stirring, and the water sample was measured by LC-ICP-MS after 8 hours, and As(III) was completely removed.

Embodiment 3

[0029] The sludge obtained after embodiment 2 was operated for 5 days, with NaAsO 2 Prepare 250mL solution containing As(III) concentration of 15mg / L as the reaction matrix of the short-range nitrification system and impact it with water. The flocculent sludge concentration VSS is 3.792g / L, and the NH 4 + -N concentration is 300mg / L, adjust pH with NaOH solution, control pH at 7.5-8.5, measure DO with dissolved oxygen analyzer, control it at 1.0-1.5, and control temperature at 30-35°C. The reaction was performed under magnetic stirring for 8 hours, and the water sample was measured by LC-ICP-MS after 8 hours, and As(III) was completely removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com