Bypass coal gas temperature decreasing, pressure reducing and afterheat recovering equipment for CCPP (Combined Cycle Power Plant) system

A waste heat recovery equipment, temperature reduction and pressure reduction technology, applied in mechanical equipment, piping systems, gas/liquid distribution and storage, etc., can solve the problems of low cooling efficiency, large metal heat exchange area, etc., to reduce labor costs, The effect of enhancing heat exchange efficiency and reducing purification costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

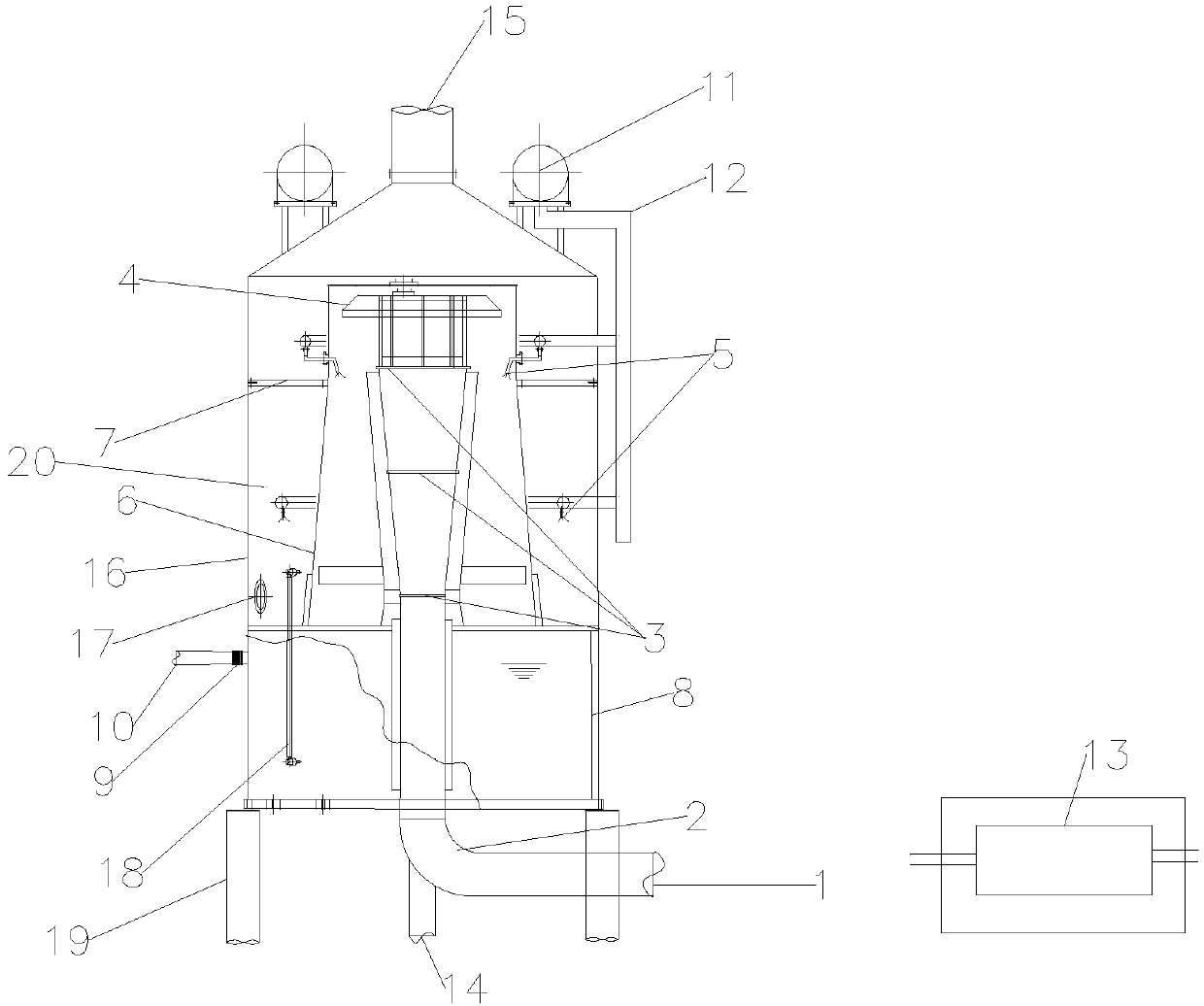

[0027] Such as figure 1 As shown, a CCPP system bypass gas temperature reduction and pressure reduction and waste heat recovery equipment includes a base 19, an equipment shell 16 above the base 19, and a gas pipeline 2. The top of the equipment shell 16 is provided with a gas outlet 15, which The lower part is a sump 8, and the outer side of the sump 8 is connected with a hot water pipe 10; above the sump 8, a diffusion pipe 6 is arranged; a gas channel 20 is formed between the diffusion pipe 6 and the equipment casing 16, and a Mist eliminator 7, the bottom end of this diffuser pipe 6 communicates with sump 8 and gas channel 20 respectively; Described gas pipe 2 enters equipment shell 16 from the bottom end of equipment shell 16 and extends in the diffuser pipe 6, and it is in One end outside the equipment shell 16 has a gas pipeline inlet 1, and a number of decompression orifice plates 3 are arranged in the pipe, and the decompression orifice plate 3 here can be a porous de...

Embodiment 2

[0035] Such as figure 1 As shown, on the basis of Example 1, the gas pipeline 2 and the diffusion pipeline 6 are made of anti-corrosion materials, which can effectively prevent gas and impurities from corroding each pipeline and affecting the normal operation of the equipment.

Embodiment 3

[0037] Such as figure 1 As shown, the walls of gas pipeline 2 and diffusion pipeline 6 described in Example 1 are all provided with anti-corrosion coatings, which can effectively prevent gas and impurities from corroding each pipeline and affect the normal operation of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com