Film-coating method of liquid crystal panel

A liquid crystal panel and coating technology, which is applied in sputtering, ion implantation, vacuum evaporation, etc., can solve problems such as easy generation of bubbles in liquid crystal panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

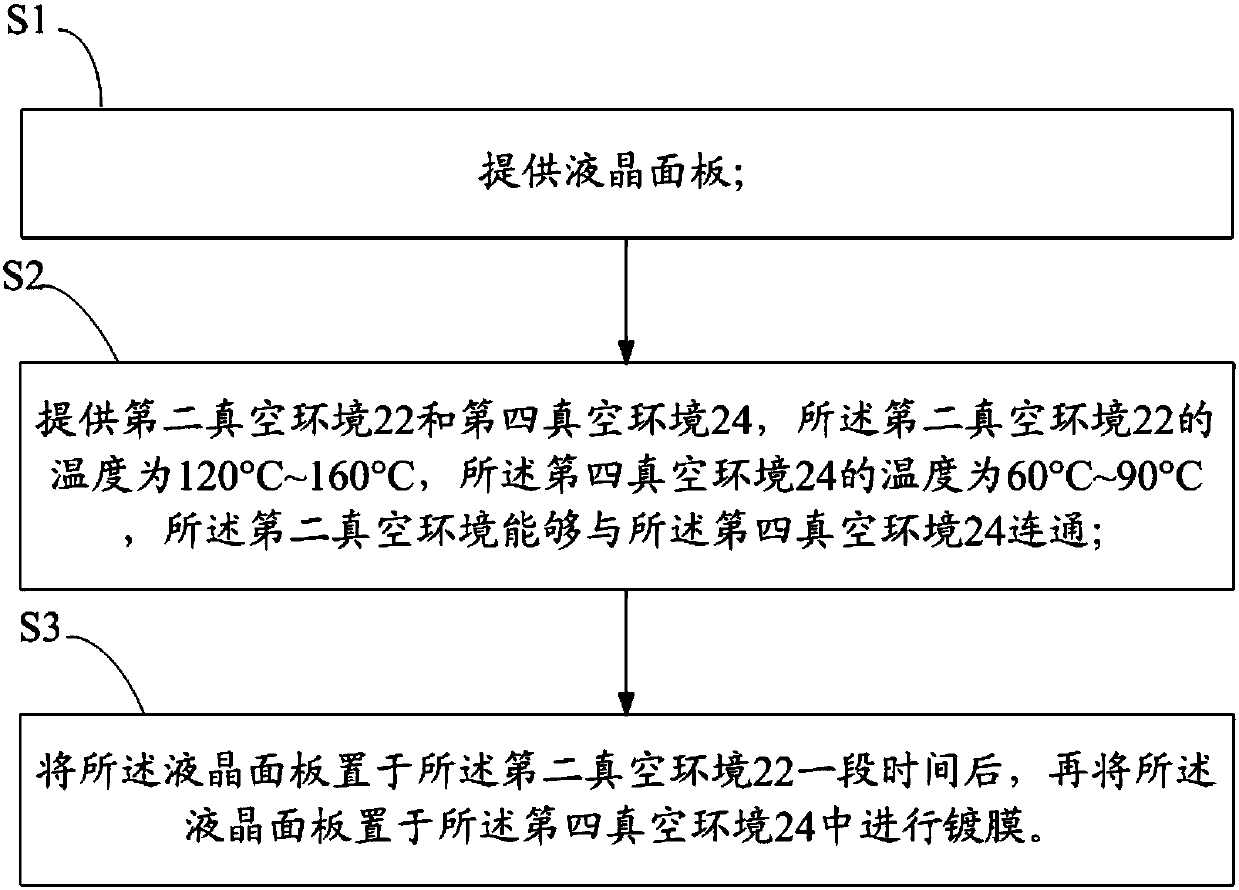

Method used

Image

Examples

Embodiment 1

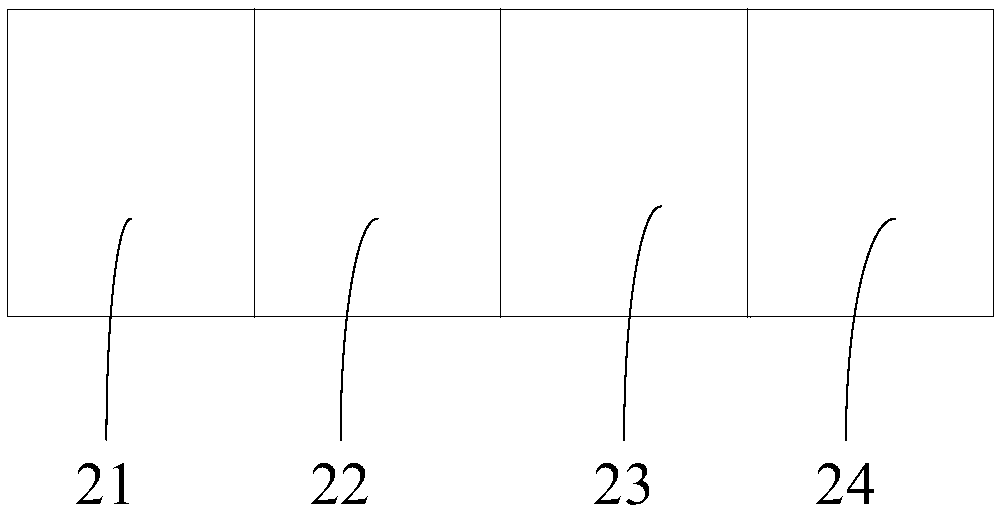

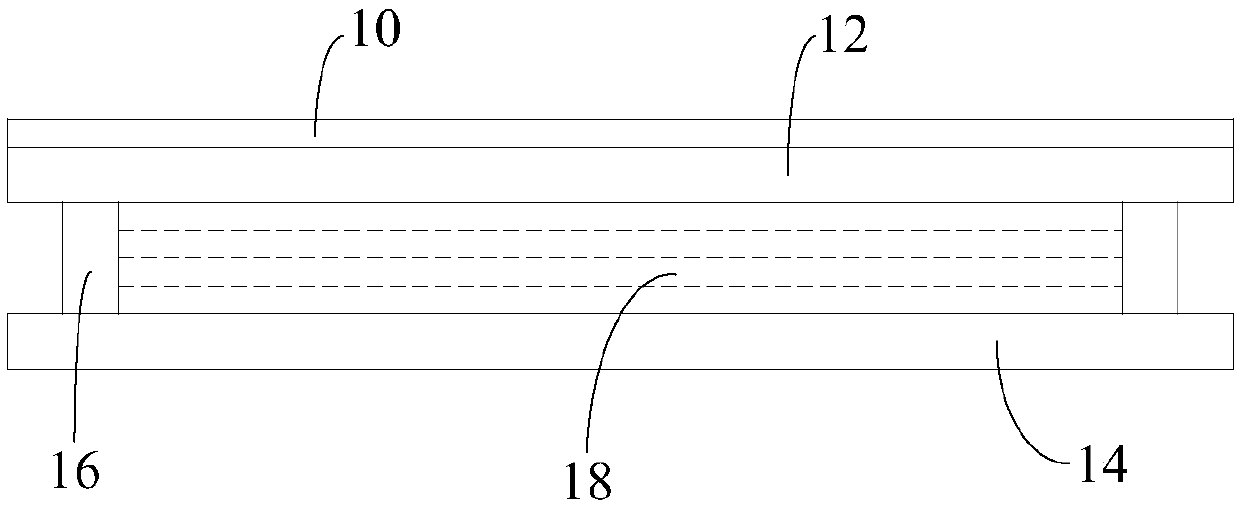

[0035] After washing the liquid crystal panel with pure water, put the liquid crystal panel into the plasma cleaning chamber 21, and use the atmospheric pressure Glow (glow) type plasma technology to perform plasma cleaning on the liquid crystal panel, specifically, use RF radio frequency as the excitation energy , the working frequency of the RF radio frequency is 13.56MHZ, using argon as the reaction gas, the flow rate is 10SCCM, and bombarding the liquid crystal panel for 30 seconds, the thickness of the liquid crystal panel can be reduced by 5nm-10nm. The pressure of the plasma cleaning chamber 20 is 10Pa to 50Pa, and the temperature of the plasma cleaning chamber is 80±5°C.

[0036] The washed liquid crystal panel is placed in the film feeding chamber 22 for 20 seconds, the vacuum pressure of the film feeding chamber 22 is 1Pa to 10Pa, and the temperature is 150±5°C. Then place the liquid crystal panel in the buffer chamber 23 for 20 seconds, the vacuum pressure of the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com