Large-size Yb,R:CaF2/SrF2 laser crystal and preparation method thereof

A technology of laser crystal and crystal growth, which is applied to lasers, crystal growth, laser components, etc. It can solve the problems of low fluorescence quantum efficiency and difficult crystal preparation, and achieve the effects of reducing temperature gradient, reducing thermal stress, and inhibiting cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

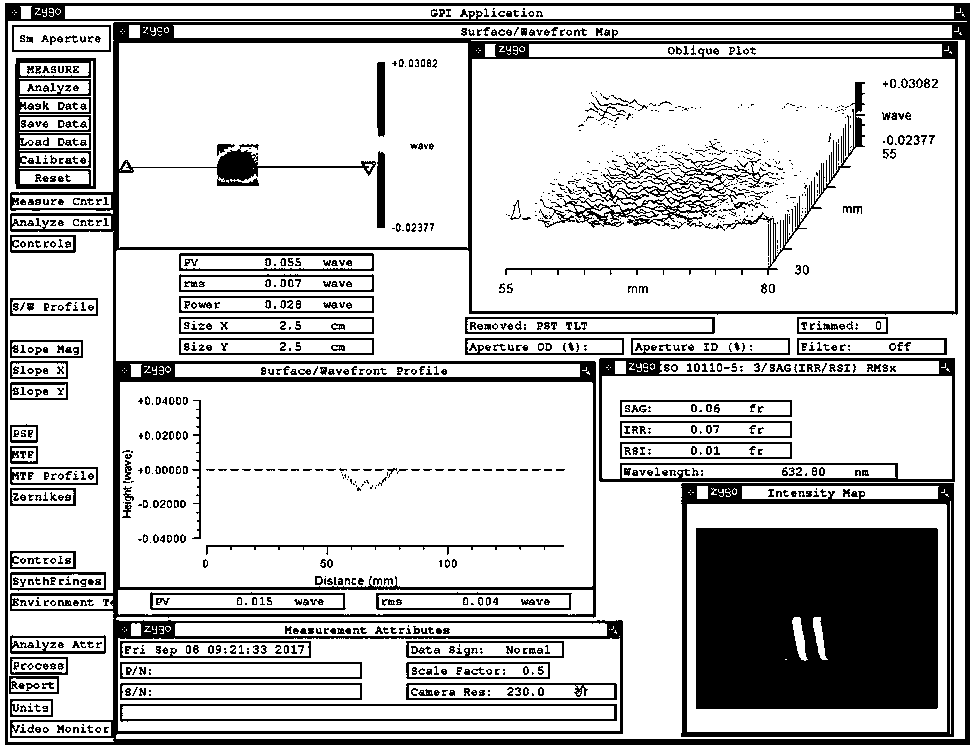

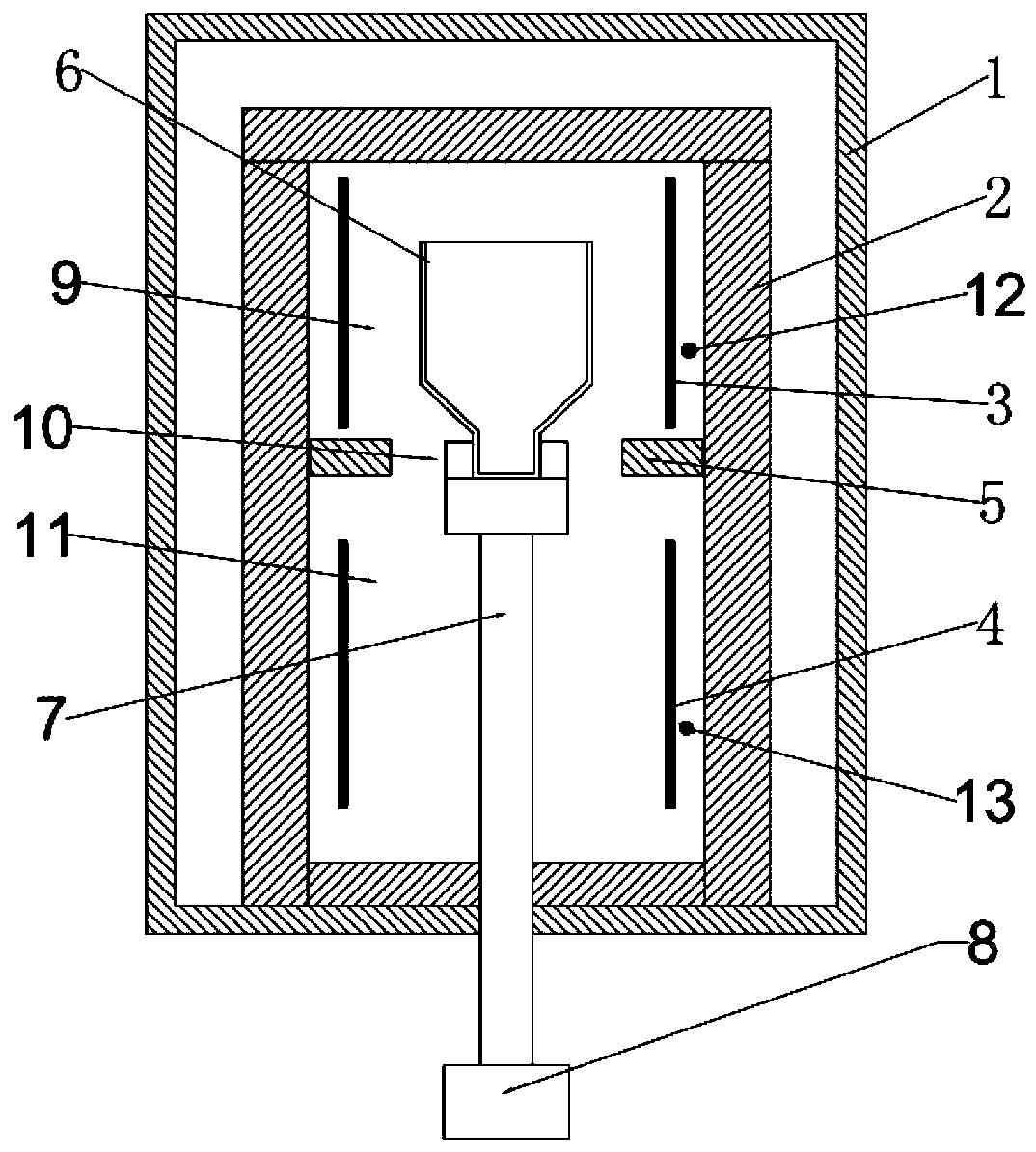

Method used

Image

Examples

Embodiment 1

[0050] Growth Yb,Y:CaF 2 Laser crystal, the specific preparation method is as follows:

[0051] Select high-purity (99.99%) YbF 3 , YF 3 and CaF 2 As a raw material, 12kg is prepared in a molar ratio of 0.03:0.05:1, and 0.5wt% of PbF is added at the same time 2 Mix well after being used as an oxygen scavenger; choose CaF in the direction of Φ35mm×40mm[111] 2 The crystal is used as the seed crystal, and the 30mm thick graphite felt is used as the heat shield. Put the seed crystal and raw materials into the graphite crucible together, then place it on the crucible water-cooled support rod and fix it, then raise the crucible to the appropriate position in the gradient area (the upper end surface of the seed crystal is parallel to the upper surface of the heat shield), and the closed furnace chamber starts to pump Vacuum, when vacuum degree≤5×10 -3 After pa, start to heat up the chemical material at a rate of 50°C / h; when the temperature of the monitoring thermocouple at the...

Embodiment 2

[0053] Growth of Yb,La:CaF 2 Laser crystal, the specific preparation method is as follows:

[0054] Select high-purity YbF 3 、LaF 3 and CaF 2 As a raw material, 15kg is prepared in a molar ratio of 0.02:0.05:1, and 0.8wt% of PbF is added at the same time 2 After being used as an oxygen scavenger, mix well; choose CaF in the direction of Φ40mm×40mm[111] 2 The crystal is used as the seed crystal, and the 50mm thick medium-coarse graphite is used as the heat shield. Put the seed crystal and the raw material into the graphite crucible together, then place it on the crucible water-cooled support rod and fix it, then lift the crucible to the appropriate position in the gradient area (the upper end surface of the seed crystal is 10mm higher than the upper surface of the heat shield), and the closed furnace chamber starts Vacuuming, when the vacuum degree is ≤5×10 -3 Pa filled with high-purity Ar and CF 4 The mixed gas (ratio: 0.95:0.05) was used as a protective atmosphere, and...

Embodiment 3

[0056] Growth of Yb,Gd:CaF 2 Laser crystal, the specific preparation method is as follows:

[0057] Select high-purity YbF 3 , GdF 3 and CaF 2 As a raw material, 15kg is prepared in a molar ratio of 0.05:0.05:1, and 0.5wt% of PbF is added at the same time 2 Mix well after being used as an oxygen scavenger; choose CaF in the direction of Φ50mm×40mm[111] 2 The crystal is used as the seed crystal, and the 40mm thick medium-coarse graphite is used as the heat shield. Put the seed crystal and the raw material into the graphite crucible together, then place it on the crucible water-cooled support rod and fix it, then lift the crucible to the appropriate position in the gradient area (the upper end surface of the seed crystal is 10mm higher than the upper surface of the heat shield), and the closed furnace chamber starts Vacuuming, when the vacuum degree is ≤5×10 -3 Pa filled with high-purity Ar and CF 4 The mixed gas (ratio: 0.95:0.05) was used as a protective atmosphere, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com