Novel longitudinal fully-through maintenance channel for water gate

A technology of maintenance channel and longitudinal channel, which is applied in the field of new-type sluice vertical full-through maintenance channel, which can solve the problems of hidden safety hazards in connection processing, high construction difficulty, and difficult maintenance, so as to achieve safe and reliable structural layout and save setting and maintenance , clean and beautiful structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

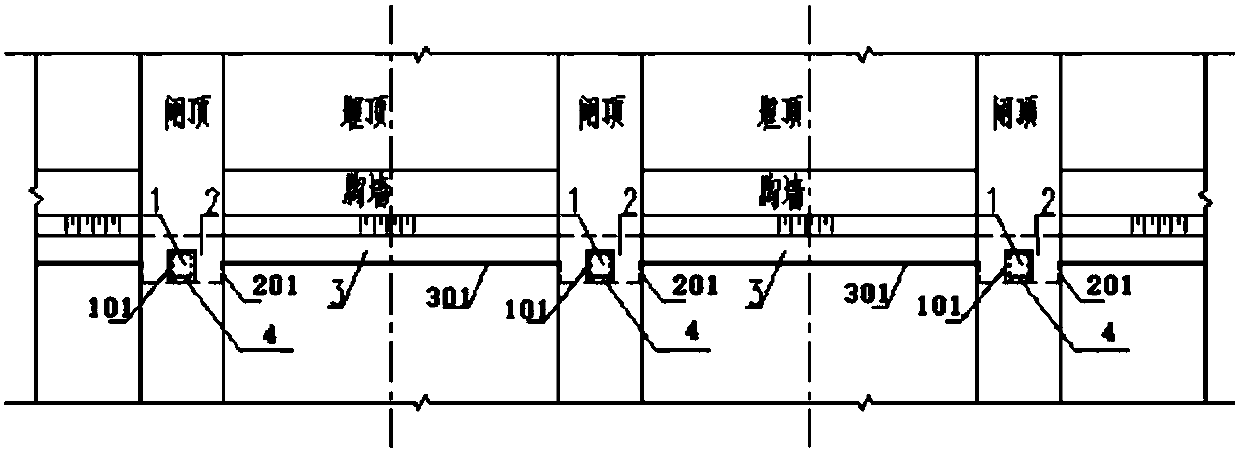

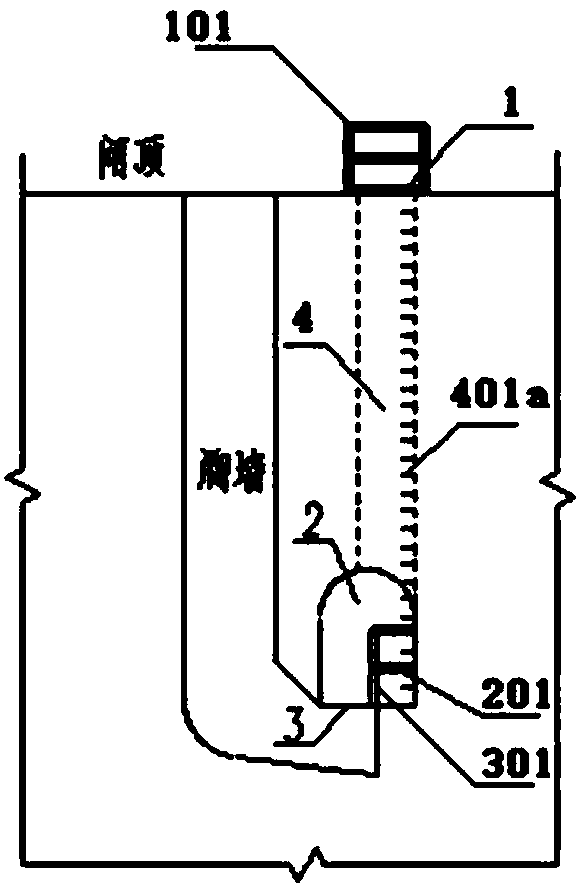

[0047] Such as figure 1 and figure 2 A new type of sluice shown is a longitudinal full-through inspection channel, including a manhole 1 set in the gate pier and a through corridor 2 that runs through the gate pier. The manhole 1 enters the through corridor 2 through the passage 4, and the through passage 2 The longitudinal channel 3 on the top of the lintel beam on the downstream side of the parapet wall on both sides, the longitudinal channel 3 is a horizontal channel perpendicular to the direction of water flow, and connected horizontally so as to fully penetrate all the gate holes in the longitudinal direction. 2 is formed by the opening of the original gate maintenance recess. The angle between the manhole 1 and the vertical is 0°. In order to ensure the safety of the gate top, the manhole 1 is also equipped with a steel cover plate 101 and a safety guardrail 102. The passageway 4 is set in the form of a steel ladder 401a, safety guardrails 201 and 301 are installed thr...

Embodiment 2

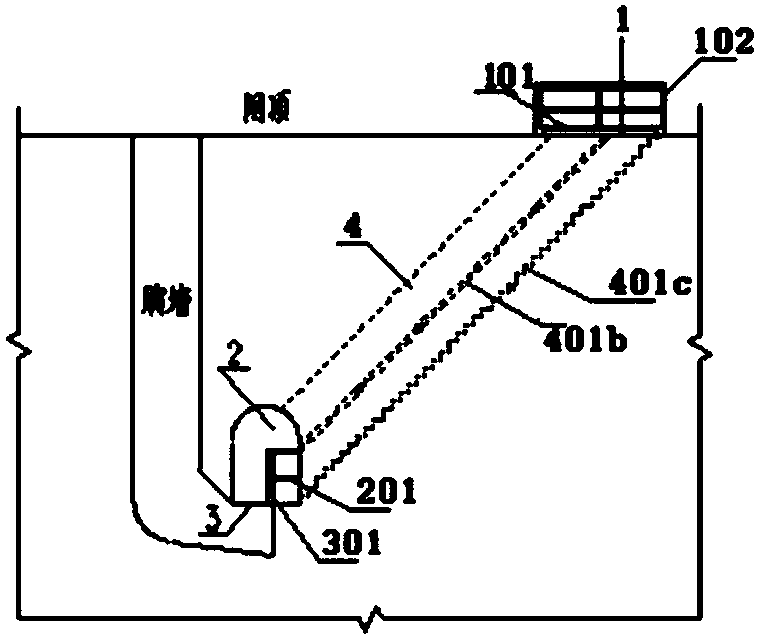

[0050] Such as image 3 A new type of sluice is shown that runs through the maintenance channel longitudinally. The channel of this embodiment is similar to that of embodiment 1. The difference is that the angle between the manhole 1 and the vertical setting in this embodiment is 45°, and the channel 4 It is provided in the form of a concrete step ladder 401b and a safety handrail 401c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com