Method for preparing cerium dioxide having different morphologies through hydrothermal technology

A technology of cerium dioxide and hydrothermal method, which is applied in the fields of chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., and can solve the problem of low intensity of electrochemiluminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1, cubic CeO 2 preparation of

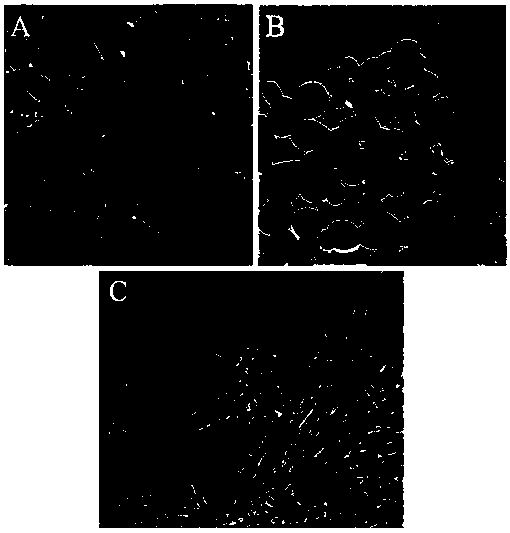

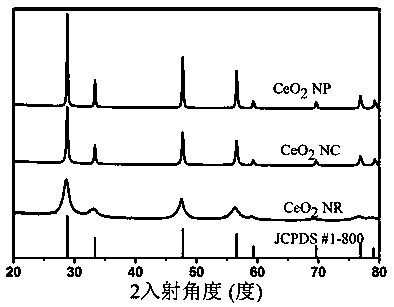

[0027] Weigh 1.736 g Ce(NO 3 ) 3 . 6H 2O was dispersed in 10 mL of ultrapure water, mixed with 70 mL of 10 mol / L NaOH solution, and stirred at room temperature for 30 min to form an emulsion; then placed in a reactor, hydrothermally reacted at 180 °C for 24 h, Centrifuge, wash with ultrapure water and ethanol three times in sequence, and dry in an oven at 70 °C for 24 h to obtain the blocky pre-product CeO 2 ; Put it into the muffle furnace after grinding, at 300 + Calcined at 5 °C for 1 h to obtain cubic CeO 2 , whose structure see figure 1 A, its crystal plane is {100}.

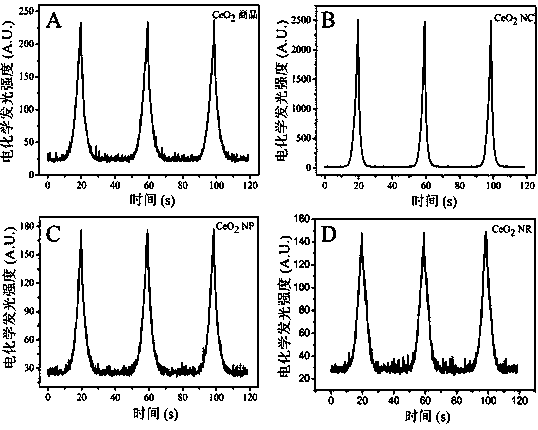

[0028] Measure its electrochemiluminescence intensity: 2500 A.U.

Embodiment 2

[0029] Embodiment 2, nanorod type CeO 2 preparation of

[0030] Weigh 1.736 g Ce(NO 3 ) 3 . 6H 2 O was dispersed in 10 mL of ultrapure water, mixed with 70 mL of 10 mol / L NaOH solution, stirred at room temperature for 30 min to form an emulsion; Centrifuge, wash with ultrapure water and ethanol three times in sequence, and place in an oven at 70 °C for 24 h to obtain the blocky pre-product CeO 2 ; After grinding, put it into the muffle furnace, at 300 + Calcined at 5°C for 1 h to obtain rod-shaped CeO 2 , whose structure see figure 1 C, whose crystal faces are {110} and {100}.

[0031] Measure its electrochemiluminescent intensity: 150 A.U.

Embodiment 3

[0032] Embodiment 3, nano particle type CeO 2 preparation of

[0033] Weigh 1.736 g Ce(NO 3 ) 3 . 6H 2 O was dispersed in 10 mL of ultrapure water, mixed with 70 mL of 10 mol / L NaOH solution, and stirred at room temperature for 30 min to form an emulsion; then placed in a reactor, hydrothermally reacted at 180 °C for 24 h, centrifuged, washed three times with ultrapure water and ethanol in sequence, and dried in an oven at 70 °C for 24 h to obtain the blocky pre-product CeO 2 ; After grinding, put it into the muffle furnace, at 800 + Calcined at 5°C for 1 h to obtain nanoparticle-type CeO 2 , whose structure see figure 1 B, its crystal plane is {111}.

[0034] Measure its electrochemiluminescence intensity: 180 A.U.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com