A radar/infrared compatible invisible coating resistant to 600 DEG C and a preparing method thereof

A coating and radar technology, applied in coating, metal material coating process, magnetic field/electric field shielding, etc., can solve the problems of difficult main bearing parts, lack of infrared stealth performance, high cost, etc., and achieve thermal shock resistance Good, wide range of regulation of dielectric properties, large design space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

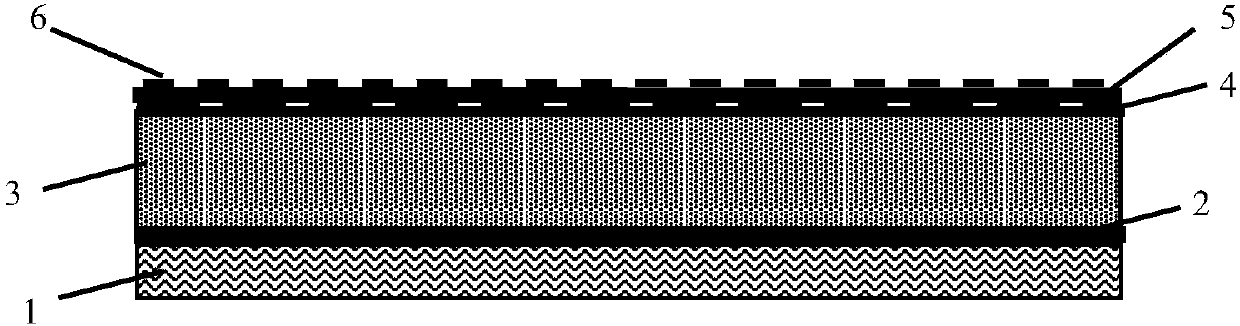

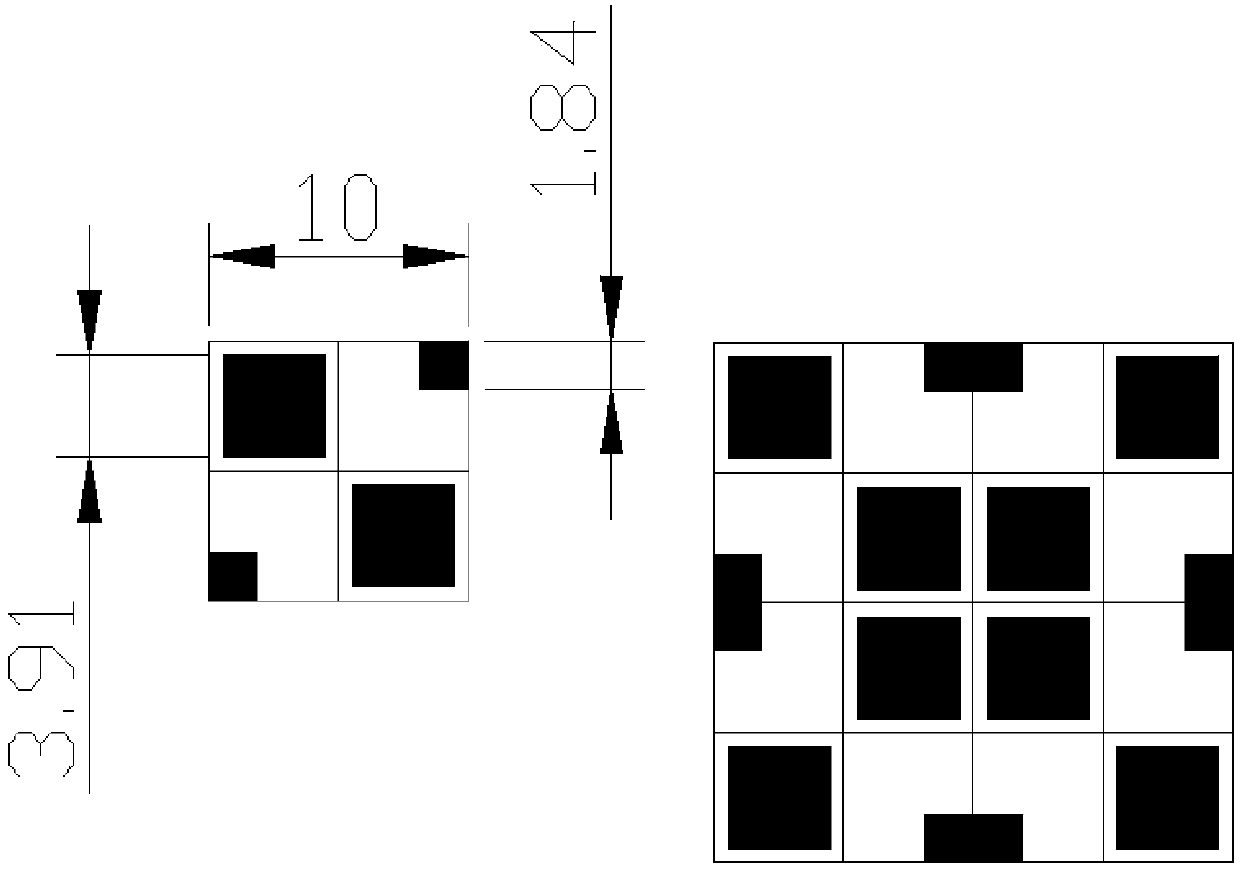

[0046] A high temperature resistant radar / infrared compatible stealth coating of the present invention, its structure is as follows figure 1 As shown, starting from the surface of metal substrate 1 (TA15 titanium alloy), from bottom to top, it includes NiCrAlY bonding layer 2, 8YSZ-Al 2 o 3 Ceramic bottom layer 3, high temperature resistance coating 4, 8YSZ isolation layer 5 and high temperature conductor coating 6; among them, the thickness of NiCrAlY bonding layer 2 is 0.1mm; 8YSZ-Al 2 o 3 8YSZ and Al in ceramic bottom layer 3 2 o 3 The mass ratio is 10:90, and its thickness is 1.0mm; the high-temperature resistance coating 4 is in the form of periodically arranged patches, and its specific structure is shown in figure 2 As shown, the periodic size of the patch is 10mm; the thickness of the high-temperature resistance coating 4 is 0.03mm; the conductive phase of the high-temperature resistance coating 4 is ruthenium dioxide, and the bonding phase is Bi 2 o 3 -SiO 2 -...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com