Restaurant waste heat recovery range hood based on oscillating heat pipe

A technology of oscillating heat pipes and waste heat recovery, which is applied in the field of energy saving, emission reduction and environmental protection. It can solve the problems of energy loss, low efficiency of waste heat recovery, and decline in heat exchange efficiency, so as to achieve effective utilization, ensure normal operation, and meet hot water demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

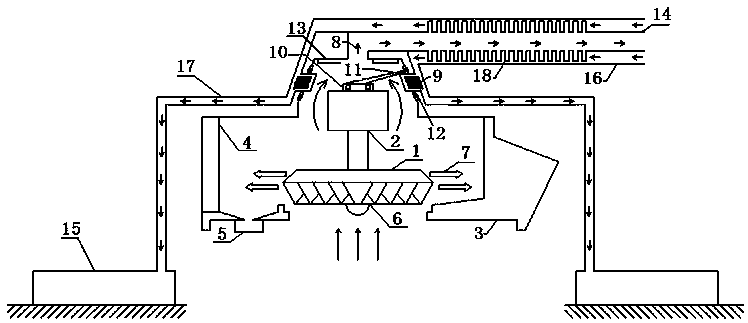

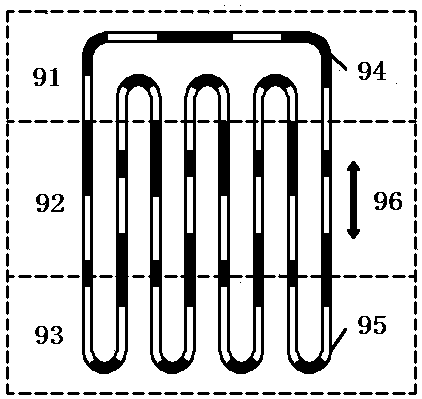

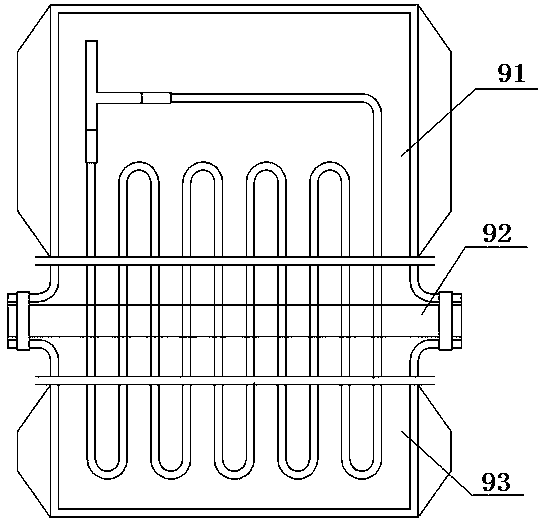

[0053] like figure 1 As shown, a restaurant waste heat recovery range hood based on an oscillating heat pipe includes an air collecting hood 3, a fan 1, an oscillating heat pipe 9, a motor 2, a dual-frequency ultrasonic generator 10, an ultrasonic transducer 12, a water tank, a lampblack concentration sensor and Gravity heat pipe18.

[0054] The top of the gas collecting hood is connected with the vertical heat exchange flue, and the top of the vertical heat exchange flue is connected with the horizontal smoke outlet pipe. Among them, the gas collection hood and the vertical heat exchange flue adopt a "round sky and place" structure, that is, the gas collection hood is also a square structure, and the vertical heat exchange flue is a round table (the cross section is circular), thereby increasing the flue gas side. heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com