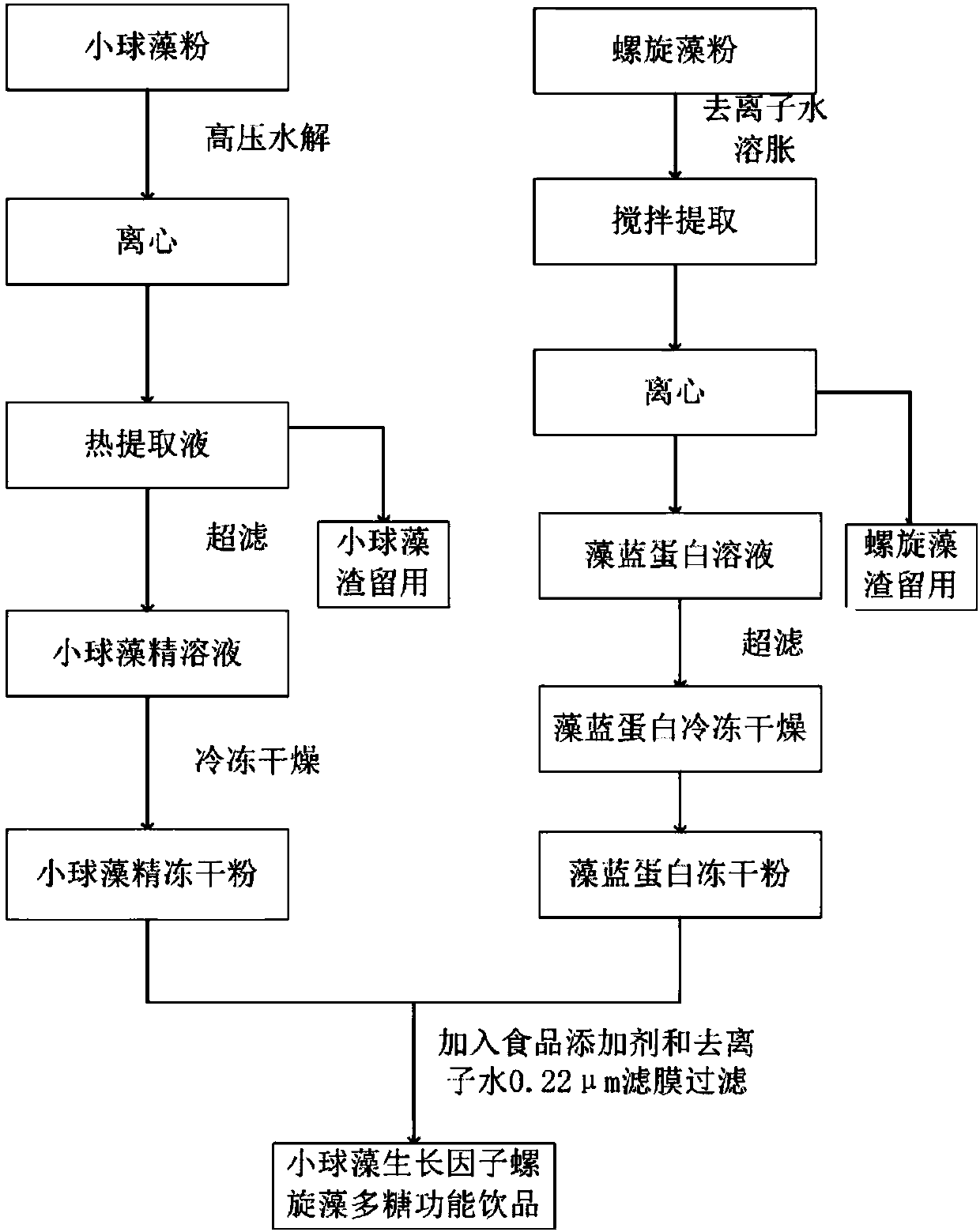

Preparation method of chlorella concentrate phycocyanin functional beverage

A technology of phycocyanin and chlorella, which is applied in the directions of protein food ingredients, protein composition of unicellular algae, functions of food ingredients, etc., to achieve the effect of small loss of biochemical activity, simple operation, and maintenance of biochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 40 grams of chlorella powder, add it into a 2L Erlenmeyer flask containing 1200 milliliters of deionized water, stir evenly, and leaching in an autoclave at 121° C. for 40 minutes.

[0030] (2) Centrifuge the leachate with a refrigerated centrifuge at 4°C and a centrifugal force of 8000g for 15 minutes, and the supernatant is the chlorella essence solution.

[0031] (3) The chlorella essence solution is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 8000Da to obtain the chlorella essence solution.

[0032] (4) Distill the chlorella essence solution to 1 / 4 volume under reduced pressure, freeze the concentrated solution in a refrigerator at -20°C, and then freeze-dry it in a freeze dryer to obtain the chlorella essence freeze-dried powder.

[0033] (5) Weigh 100 grams of spirulina powder, add it into a 2-liter beaker containing 1500 milliliters of deionized water, stir evenly, and then let stand at room temperature for 24 hours...

Embodiment 2

[0040] (1) Weigh 30 grams of chlorella powder, add it into a 2L Erlenmeyer flask containing 1200 milliliters of deionized water, stir well, and then leaching in an autoclave at 115° C. for 50 minutes.

[0041] (2) The leaching solution was centrifuged for 20 minutes at 4°C and a centrifugal force of 10,000 g in a refrigerated centrifuge, and the supernatant was the chlorella essence solution.

[0042] (3) The chlorella essence solution is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 10 000 Da to obtain the chlorella essence solution.

[0043] (4) The chlorella essence solution is distilled under reduced pressure to about 1 / 5 volume, the concentrated solution is placed in a refrigerator to freeze at -20° C., and then freeze-dried in a freeze dryer to obtain a chlorella essence freeze-dried powder.

[0044] (5) Weigh 80 grams of spirulina powder, add it into a 2-liter beaker containing 1200 milliliters of deionized water, stir evenly, and the...

Embodiment 3

[0051] (1) Weigh 30 grams of chlorella powder, add it into a 2L Erlenmeyer flask containing 1200 ml of deionized water, stir evenly, and then leaching in an autoclave at 121° C. for 60 minutes.

[0052](2) The leachate was centrifuged with a refrigerated centrifuge at 4°C and a centrifugal force of 10,000g for 20 minutes, and the supernatant was the chlorella essence solution.

[0053] (3) The chlorella essence solution is ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 10 000 Da to obtain the chlorella essence solution.

[0054] (4) Distill the chlorella essence solution to about 1 / 5 volume, put the concentrated solution in the refrigerator to freeze at -20°C, and then freeze-dry it in a freeze dryer to obtain the chlorella essence freeze-dried powder.

[0055] (5) Weigh 80 grams of spirulina powder, add it into a 2-liter beaker containing 1200 milliliters of deionized water, stir evenly, and then let stand at room temperature for 24 hours to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com