Quick-freeze cooked stretched noodle and making method thereof

A ramen and cooking technology, applied in food science, food preservation, application, etc., can solve the problems of ramen texture and tensile properties decline, taste and flavor deterioration, cooking loss reduction, etc., to achieve moderate hardness and tensile properties , save costs, and solve the effect of quality damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

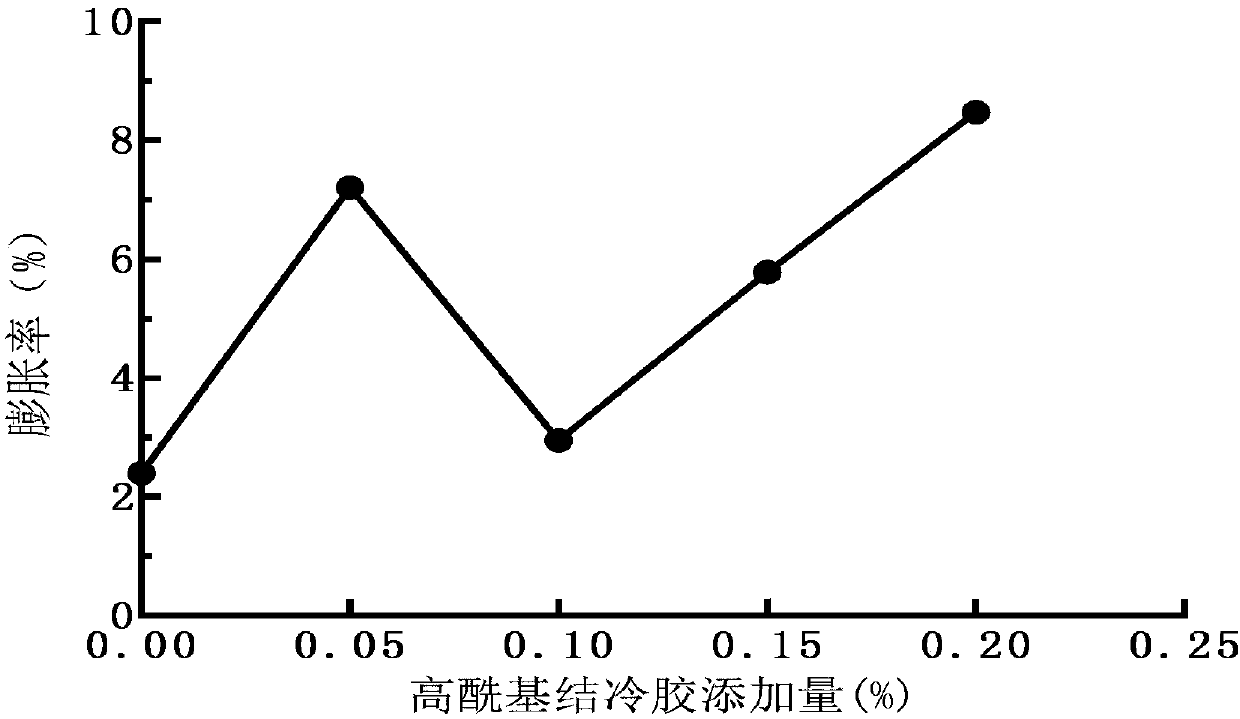

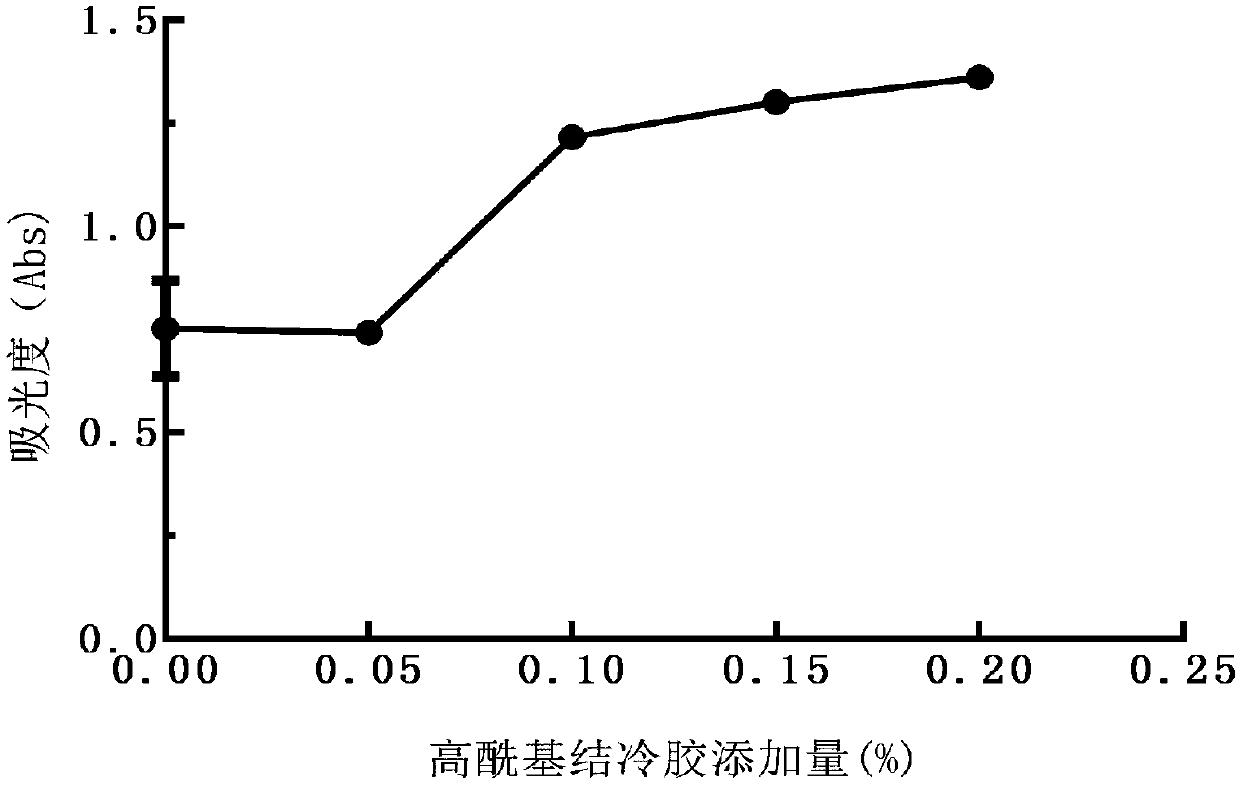

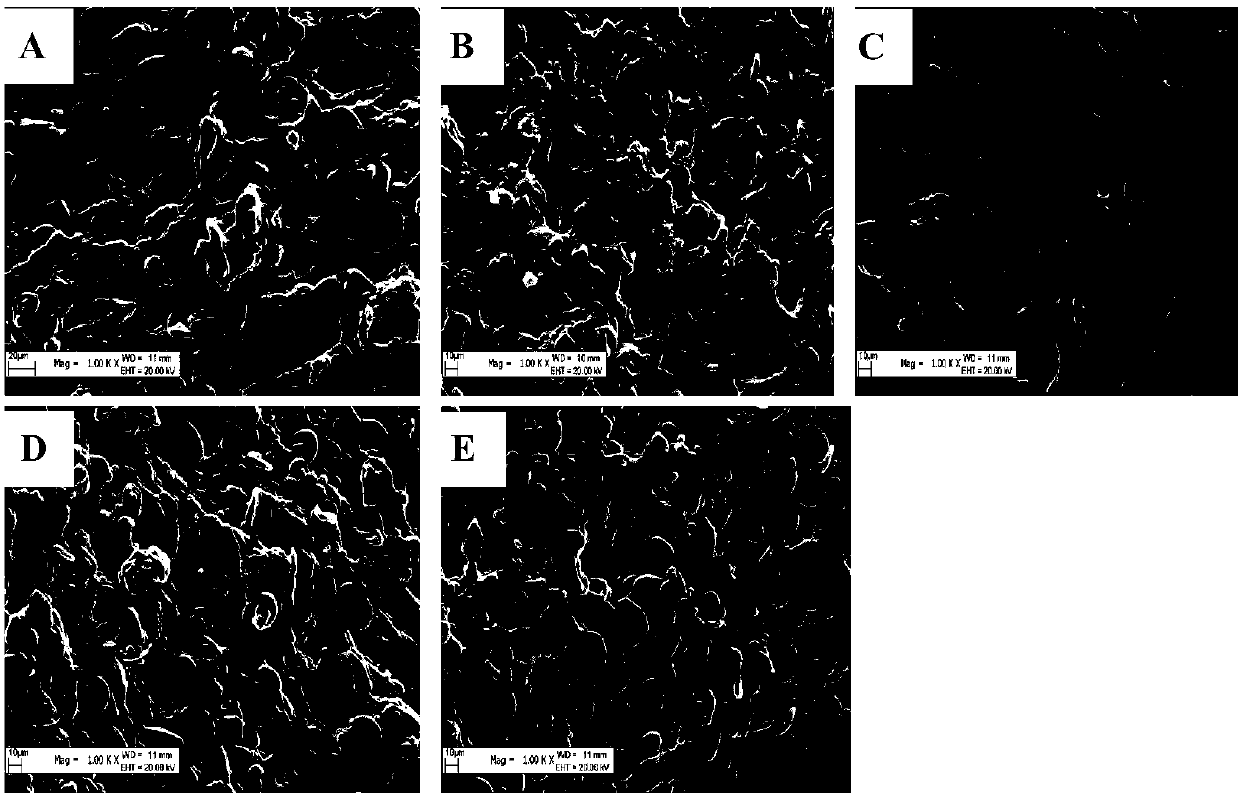

[0029] The invention provides a quick-frozen cooked ramen, which comprises 630-650 parts of flour, 370-400 parts of water, 10-12 parts of table salt, 1-2 parts of high acyl gellan gum and 10-15 parts of flaxseed powder in parts by weight. parts, trehalose 20-40 parts, linseed gum 9-15 parts.

Embodiment 2

[0031] For realizing above technical purpose, the present invention specifically provides a kind of preparation method of quick-frozen cooked hand-pulled noodles, and concrete method step is as follows:

[0032] Weigh flour, water, salt, high acyl gellan gum, linseed powder, trehalose and linseed gum according to the weight ratio of Example 1, leave it to stand for 25-35min after kneading, compound rolling, knead into dough, Let stand again for 25-35 minutes; knead the dough for the second time, cut the dough into small pieces, pull the small pieces into ramen noodles with a diameter of 0.25-0.5cm, steam for 1 minute, boil in boiling water for 1-3 minutes, and wait until the white core of the noodles disappears immediately Take out with a filter spoon, cool in cold water for 30 seconds, take out the cooled ramen noodles with a filter, drain the surface water, and dry at 80°C for 3 minutes; weigh the ramen noodles with filtered water, and freeze them in an ultra-low temperature ...

Embodiment 3

[0034] Weigh 630g of flour, 370g of water, 10g of salt, 1g of high acyl gellan gum, 10g of flaxseed powder, 20g of trehalose, and 9g of flaxseed gum. Put it aside for 25 minutes; knead the dough for the second time, cut the dough into small pieces, pull the small pieces into ramen noodles with a diameter of 0.25cm, steam for 1 minute, and cook in boiling water for 1 minute. Cool in cold water at ℃ for 30 seconds, remove the cooled ramen noodles with a strainer, drain the surface water, and dry at 80℃ for 3 minutes; weigh and divide the ramen noodles with filtered water, and store them at a temperature of -30℃ to -40℃ Freeze in an ultra-low temperature refrigerator for 30 minutes, and refrigerate at -18°C after 30 minutes for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com