Magnetism compatible water-cooling microwave ablation needle and preparation method thereof

A microwave ablation and magnetic compatibility technology, applied in the field of medical devices, can solve the problems of limiting the development of microwave tumor ablation, human injury, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention also provides a method for preparing the magnetically compatible water-cooled microwave ablation needle, comprising the following steps:

[0066] A) Connect the inner conductor and the outer conductor at the front end of the coaxial cable (2) by welding; specifically, peel off the outer conductor and the intermediate insulating layer at the front end of the coaxial cable (2), and weld the inner conductor and the outer conductor to connect.

[0067] B) On the surface of the coaxial cable (2), cut 8 to 10 annular notches communicated with the insulating medium and distributed at equal intervals from the position of the front end of the coaxial cable (2) along its axial direction;

[0068] In the present invention, the cutting method is preferably wire cutting technology.

[0069] C) Insert the non-magnetic metal ring (3) into the surface of the coaxial cable, and use an adhesive to fix the non-magnetic metal ring (3) on the side farthest from the not...

Embodiment 1

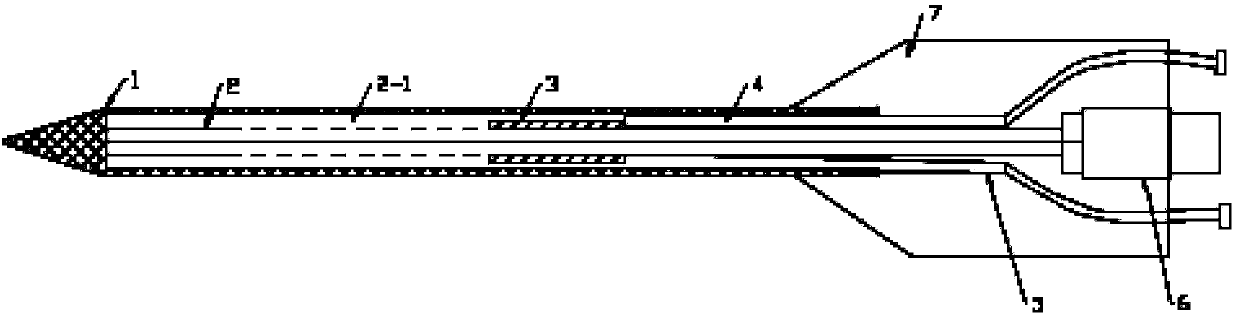

[0078] This embodiment provides a magnetically compatible water-cooled microwave ablation needle, including: a zirconia needle tube 1 , a coaxial cable 2 , a copper ring 3 , a water inlet tube 4 , a water outlet tube 5 , a radio frequency coaxial connector 6 and a needle handle 7 .

[0079] Specifically include:

[0080] A zirconia needle tube (1), the zirconia needle tube comprising a needle point and a hollow needle body;

[0081] A coaxial cable (2), the coaxial cable (2) includes an inner conductor, an insulating medium and an outer conductor, the inner conductor and the outer conductor at the front end of the coaxial cable (2) are connected and arranged on the hollow needle Inside the body, the surface of the coaxial cable is provided with 8 to 10 annular notches communicated with the insulating medium and distributed at equal intervals from the front end of the coaxial cable along its axial direction;

[0082]The non-magnetic metal ring (3) arranged inside the hollow ne...

Embodiment 2

[0095] This embodiment provides a magnetically compatible water-cooled microwave ablation needle, including: a zirconia needle tube 1 , a coaxial cable 2 , a copper ring 3 , a water inlet tube 4 , a water outlet tube 5 , a radio frequency coaxial connector 6 and a needle handle 7 .

[0096] Specifically include:

[0097] A zirconia needle tube (1), the zirconia needle tube comprising a needle point and a hollow needle body;

[0098] A coaxial cable (2), the coaxial cable (2) includes an inner conductor, an insulating medium and an outer conductor, the inner conductor and the outer conductor at the front end of the coaxial cable (2) are connected and arranged on the hollow needle Inside the body, the surface of the coaxial cable is provided with 8 to 10 annular notches communicated with the insulating medium and distributed at equal intervals from the front end of the coaxial cable along its axial direction;

[0099] The non-magnetic metal ring (3) arranged inside the hollow n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com