Full scrap steel electric arc furnace quasi-continuous steelmaking system and process

An electric arc furnace, quasi-continuous technology, applied in the quasi-continuous steelmaking system and process field of the all-scrap electric arc furnace, can solve the problems of long cycle, high smelting power consumption, speed up the smelting rhythm of the all-scrap electric arc furnace, etc., and reach the power consumption per ton of steel The effect of reducing and improving dephosphorization efficiency and reducing the time of pouring molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

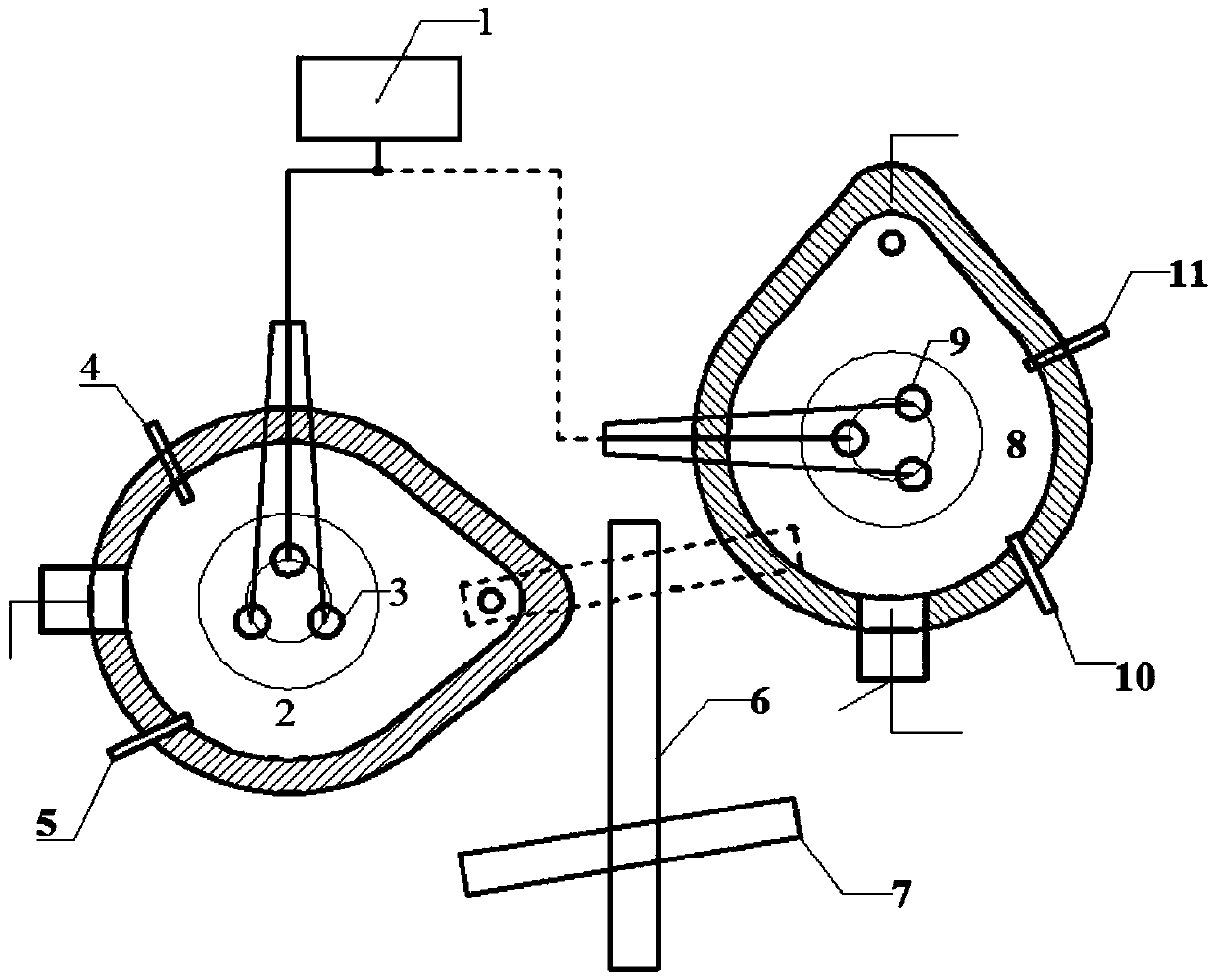

Method used

Image

Examples

Embodiment 1

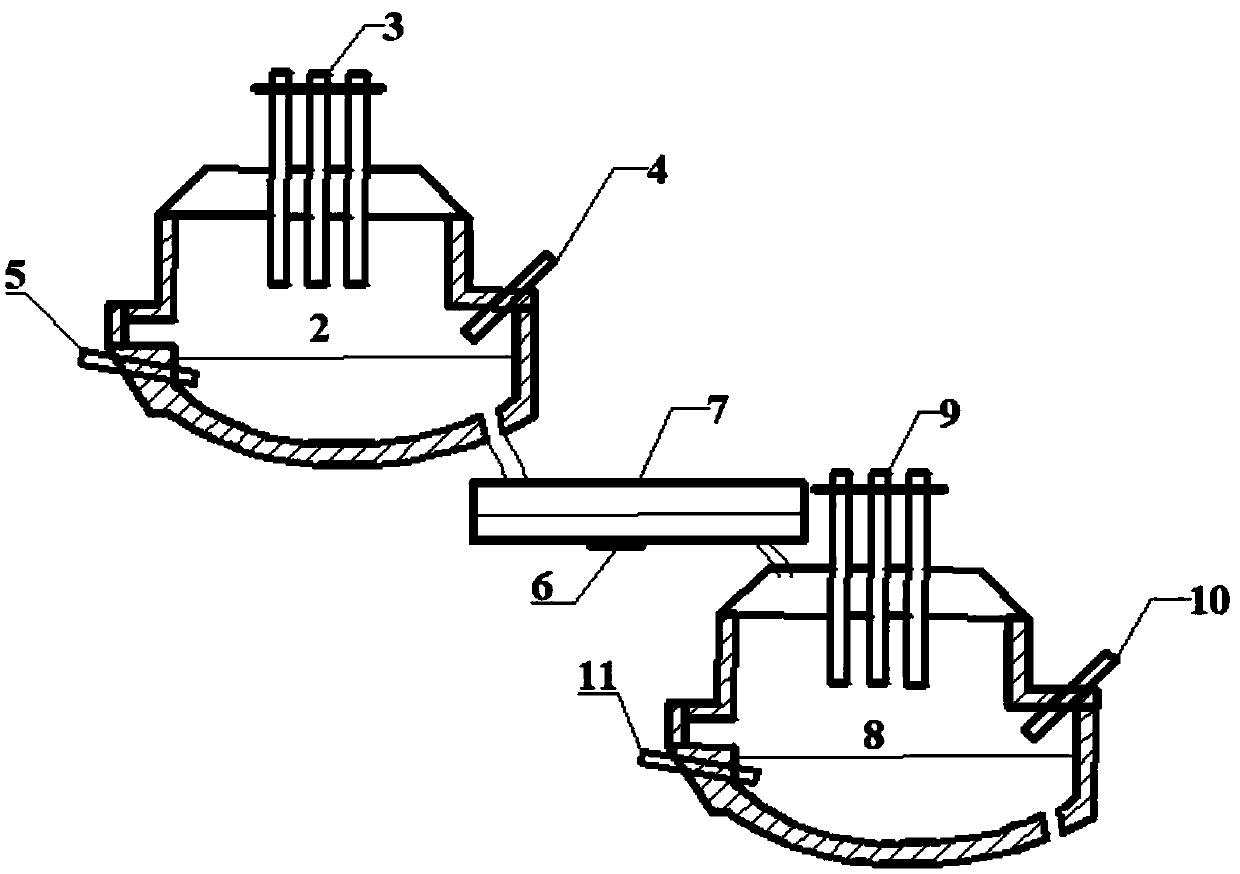

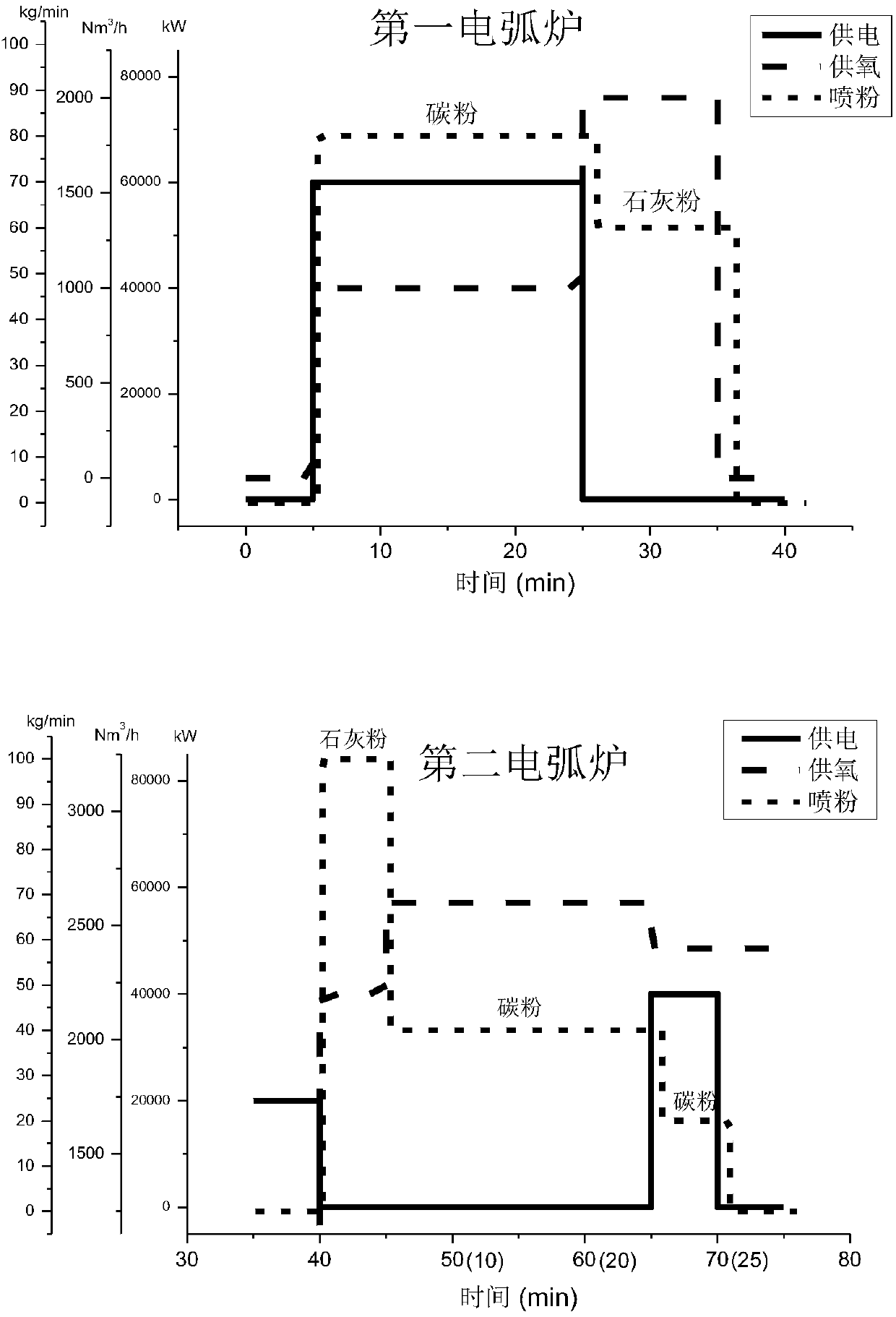

[0053] In this embodiment, the process of the present invention is applied to smelting low-carbon steel in a 70t+70t electric arc furnace, and the specific process is as follows:

[0054] (1) 0~5min: This stage is the feeding period of the first electric arc furnace:

[0055] Specific process: Add steel scrap, lime, auxiliary materials and carbon powder for smelting into the first electric arc furnace;

[0056] Among them, the method of feeding scrap steel into the furnace is the feeding method of the material basket. Lime and auxiliary materials are added to the dephosphorization electric arc furnace together with the scrap steel. The amount of lime added per ton of steel is 15kg; Adding (or spraying) amount is 50kg;

[0057] (2) 5~25min: This stage is the scrap steel melting period of the first electric arc furnace:

[0058] Specific process: electricity is used to melt scrap steel, the electrode power supply is 60000kW, the furnace wall cluster oxygen lance is in the burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com