Reflective optical pressure sensor

A pressure sensor and reflective technology, applied in the field of sensors, can solve the problems of inconvenient operation, inability to give full play to the advantages of optical pressure sensors, and small space, etc., and achieve the effect of simple operation, high reliability, and fewer optical path components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

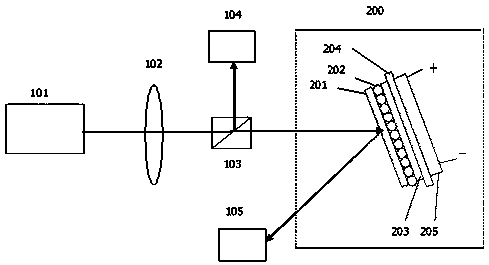

[0014] Such as figure 1 The schematic structural diagram of the reflective optical pressure sensor device shown includes a light source emitter 101; a lens 102; a beam splitter 103; a first light intensity detector 104; a second light intensity detector 105 and a detection unit 200, and the detection unit 200 includes from A glass sheet 201, a silicon dioxide sphere layer 202, a garnet 203, an aluminum film 204 grown on the garnet by magnetron sputtering, and a last layer of graphite 205 that are energized at both ends are sequentially laminated from top to bottom.

[0015] The laser output from the laser transmitter is focused and output by the lens 102 and then split by the beam splitter 103. One beam is reflected and directly received by the first light intensity detector 104, and the other beam is transmitted into the detection unit 200, and the incident light is obliquely incident on the detection unit. On the glass sheet 201, after penetrating the glass sheet 201, passin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com