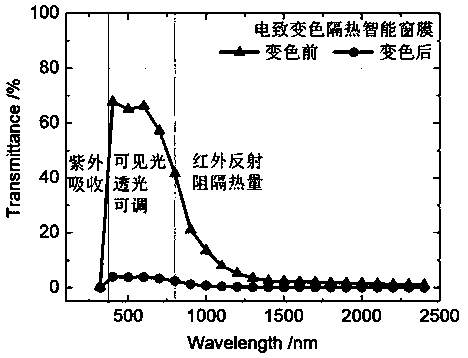

Flexible electrochromic thermal insulating intelligent window film and preparation technology thereof

A preparation process and electrochromic technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as the application of difficult large-size flexible electrochromic films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

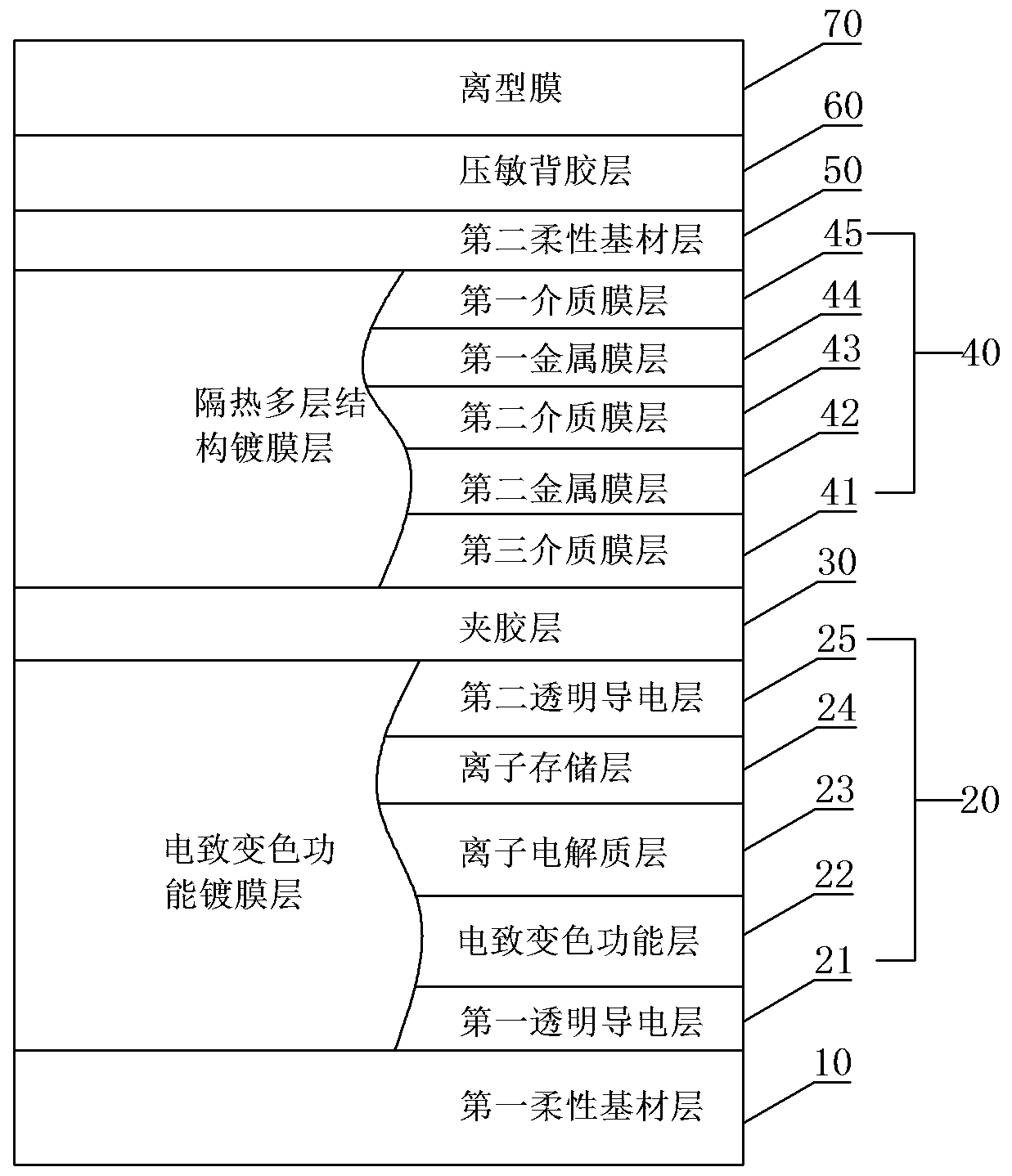

[0059] Embodiment 1: A flexible electrochromic heat-insulating smart window film, the film structure of the window film includes the following layers compounded in sequence:

[0060] a first flexible substrate film 10;

[0061] The electrochromic functional coating layer 20 includes a first transparent conductive layer 21, an electrochromic functional layer 22, an ion electrolyte layer 23, an ion storage layer 24, and a second transparent conductive layer 25 compounded in sequence;

[0062] Interlayer 30;

[0063] The heat-insulating multi-layer structure coating layer 40 includes multiple layers of alternately compounded dielectric film layers 41, 43, 45 and metal film layers 42, 44;

[0064] In this embodiment, the heat-insulating multilayer structure coating layer 40 includes a first dielectric film layer 45, a first metal film layer 44, a second dielectric film layer 43, a second metal film layer 42, and a third dielectric film layer compounded in sequence. Layer 41, whe...

Embodiment 2

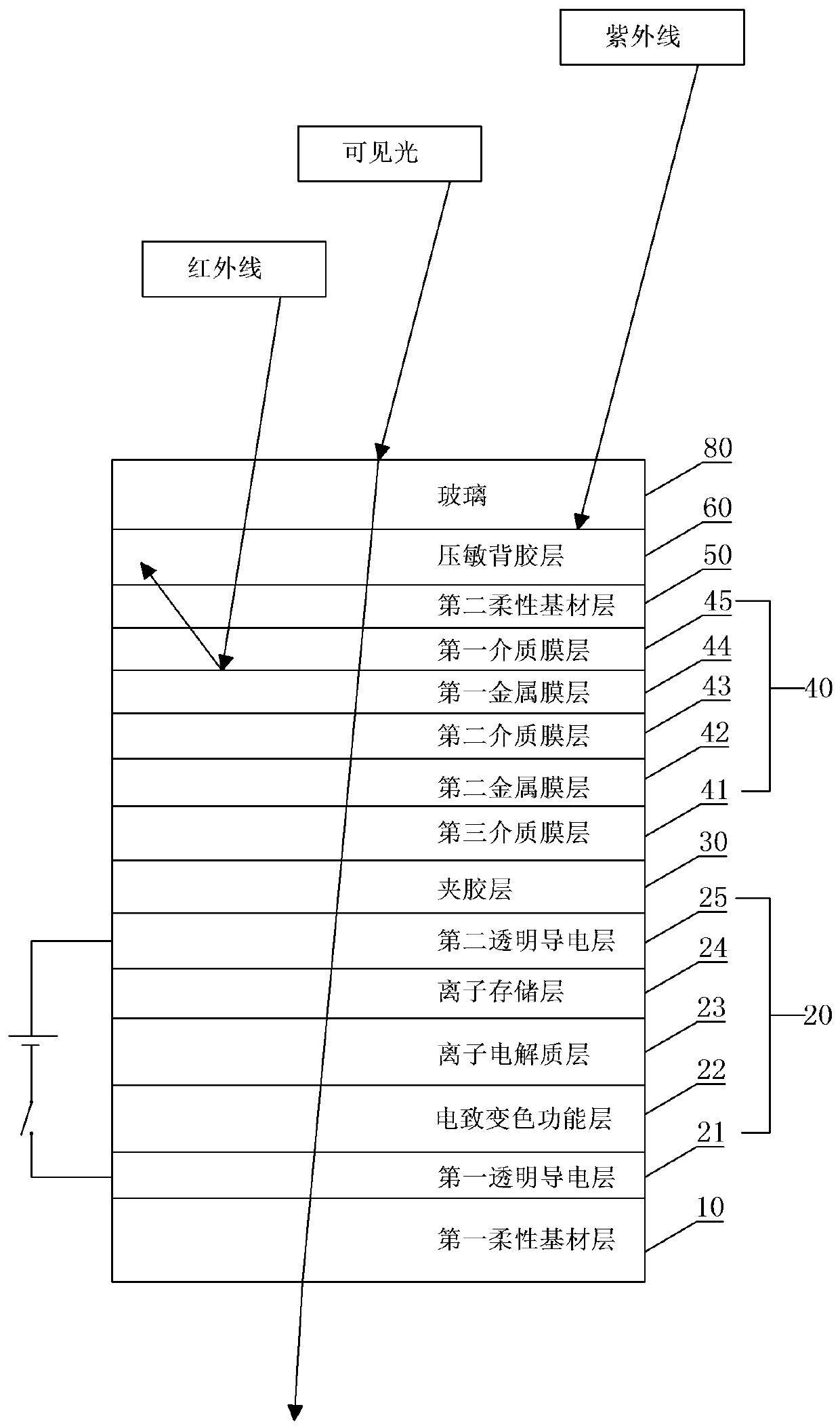

[0084] Embodiment 2: Application of a flexible electrochromic heat-insulating smart window film of the present invention: the above-mentioned window film is directly applied to the inner surface of the window glass, and the application method is to tear off the release film 70 and stick a film on the surface of the window glass 80 .

Embodiment 3

[0085] Embodiment 3: Application of a flexible electrochromic heat-insulating intelligent window film of the present invention: the above-mentioned window film is applied to the production of double-layer laminated glass, and the application method is to sandwich the window film between two pieces of glass, and then laminate Process preparation can get double-layer laminated glass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Square resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com