Single-blade lateral milling method based on torsional ultrasonic vibration

A technology of ultrasonic vibration and milling, which is applied in the direction of using vibration fluid, milling machine equipment, milling machine equipment details, etc., to achieve the effects of high machining surface accuracy, reducing cutting force, and expanding the types of tool paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings.

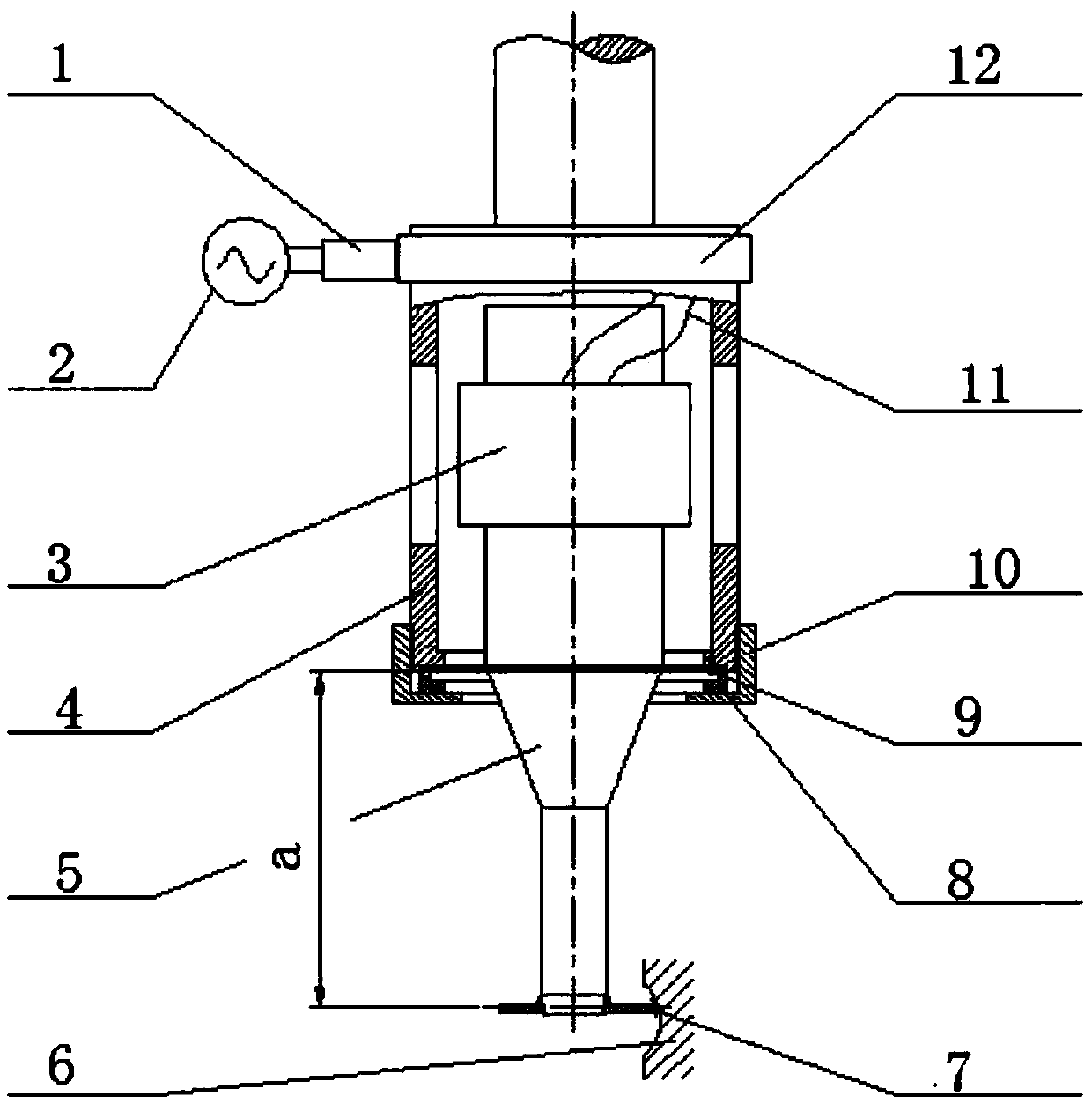

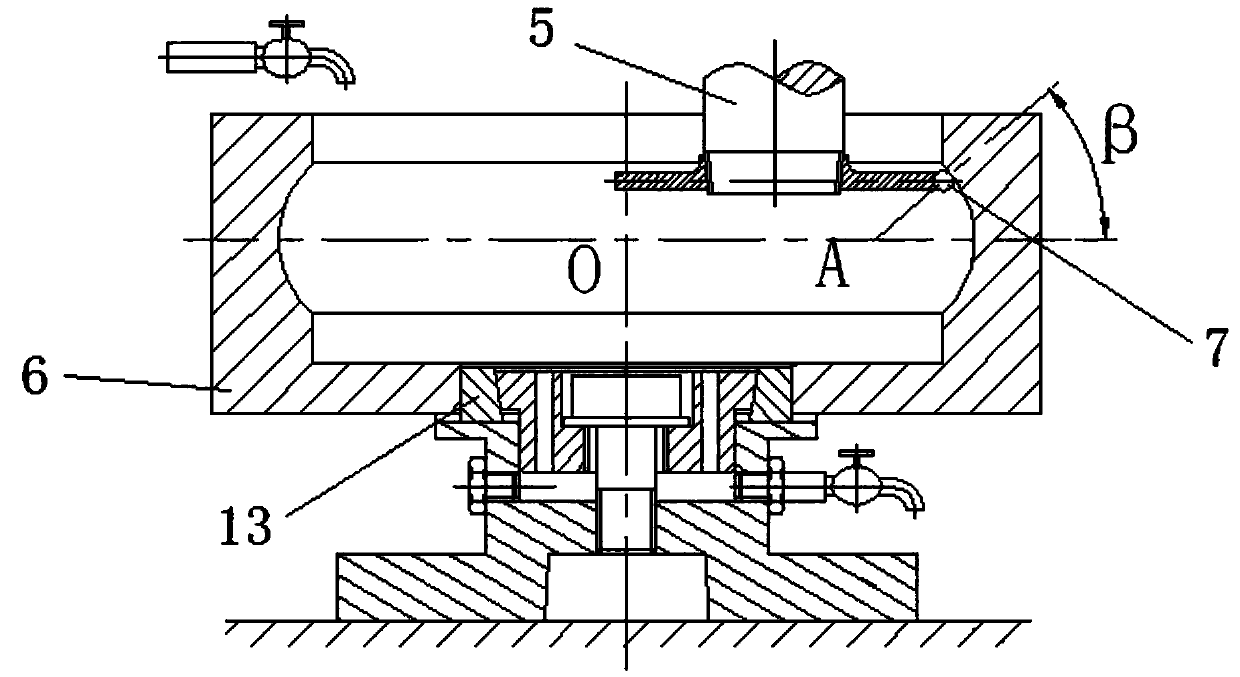

[0055] like Figure 1 to Figure 3 As shown, a single-blade lateral milling method based on torsional ultrasonic vibration adopts a milling method combining single-blade side milling and ultrasonic machining. Device 3, support sleeve 4, horn 5 and single-edged milling cutter 7, etc. The transducer 3 connected to the horn 5 is located inside the support sleeve 4, avoiding direct contact with the external environment and ensuring safe operation; The generator 2 is connected to realize the ultrasonic signal input in the rotating state of the single-edged milling cutter.

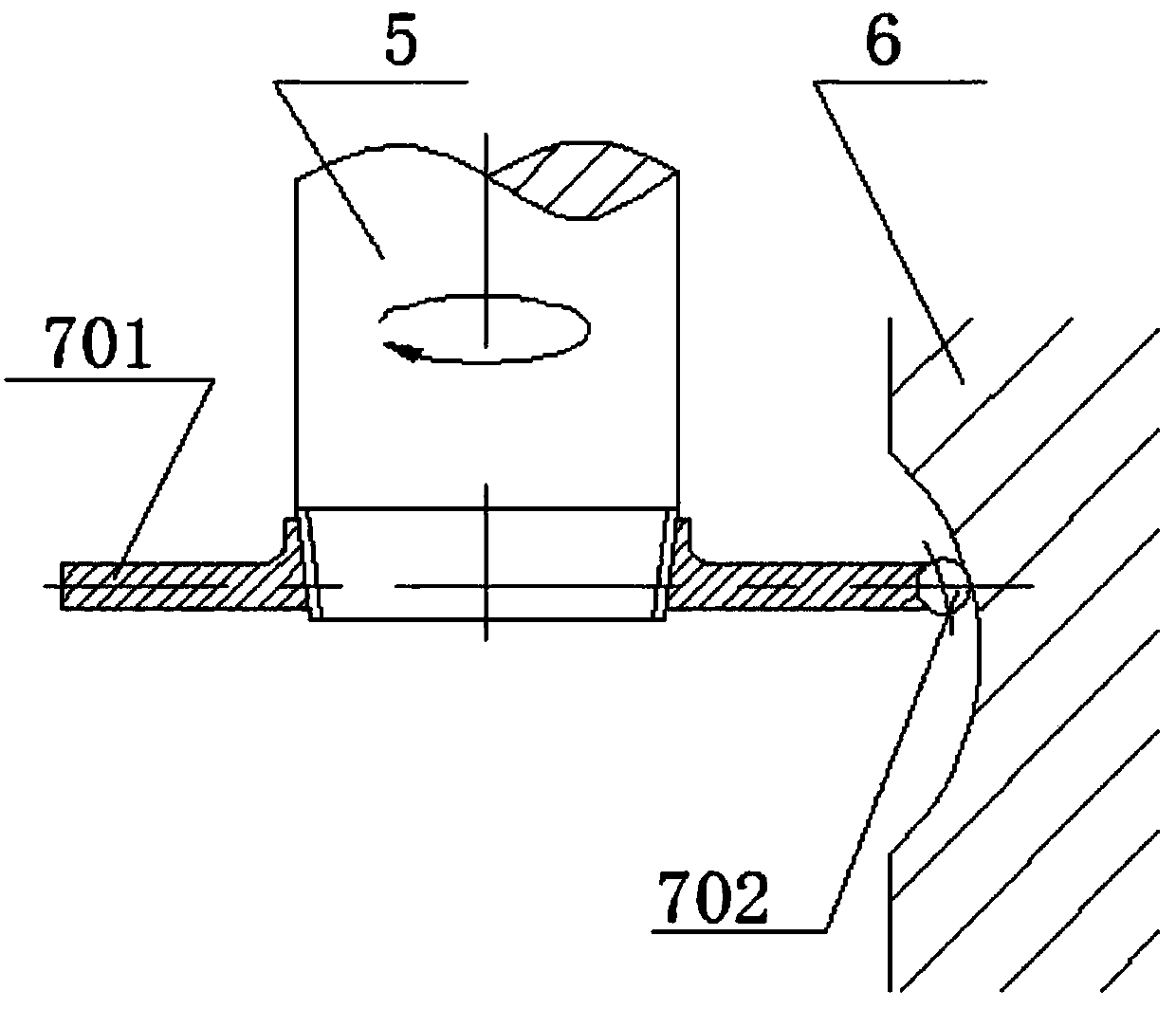

[0056] The end of the horn 5 is equipped with a single-edged milling cutter 7, the single-edged milling cutter 7 is composed of a disc 701 and a single cutter head 702 fixed on the circumference of the disc, the single-edged milling cutter 7 is connected with the horn 5 through a tapered thread , The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com