TPU composite material

A technology of composite materials and raw materials, applied in the direction of synthetic resin layered products, lamination, coating, etc., can solve the problems of TPU thickness reduction, silica gel application restrictions, low raw material utilization, etc., and achieve the effect that the adhesion will not decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A TPU composite material comprises a silica gel layer 1 and a TPU film 2 which are compounded and connected to each other. The thickness of the silica gel layer 1 is 0.01-10 mm. The TPU film 2 is made of a TPU film with a melting point above 50°C.

[0030] The silica gel layer 1 is formed on the TPU film 2 by compounding silica gel raw materials, and the components of the silica gel raw materials are:

[0031] Vinyl polydimethylsiloxane, filler, platinum catalyst, inhibitor, hydrogen-containing silicone oil, color paste, color paste depends on the desired color.

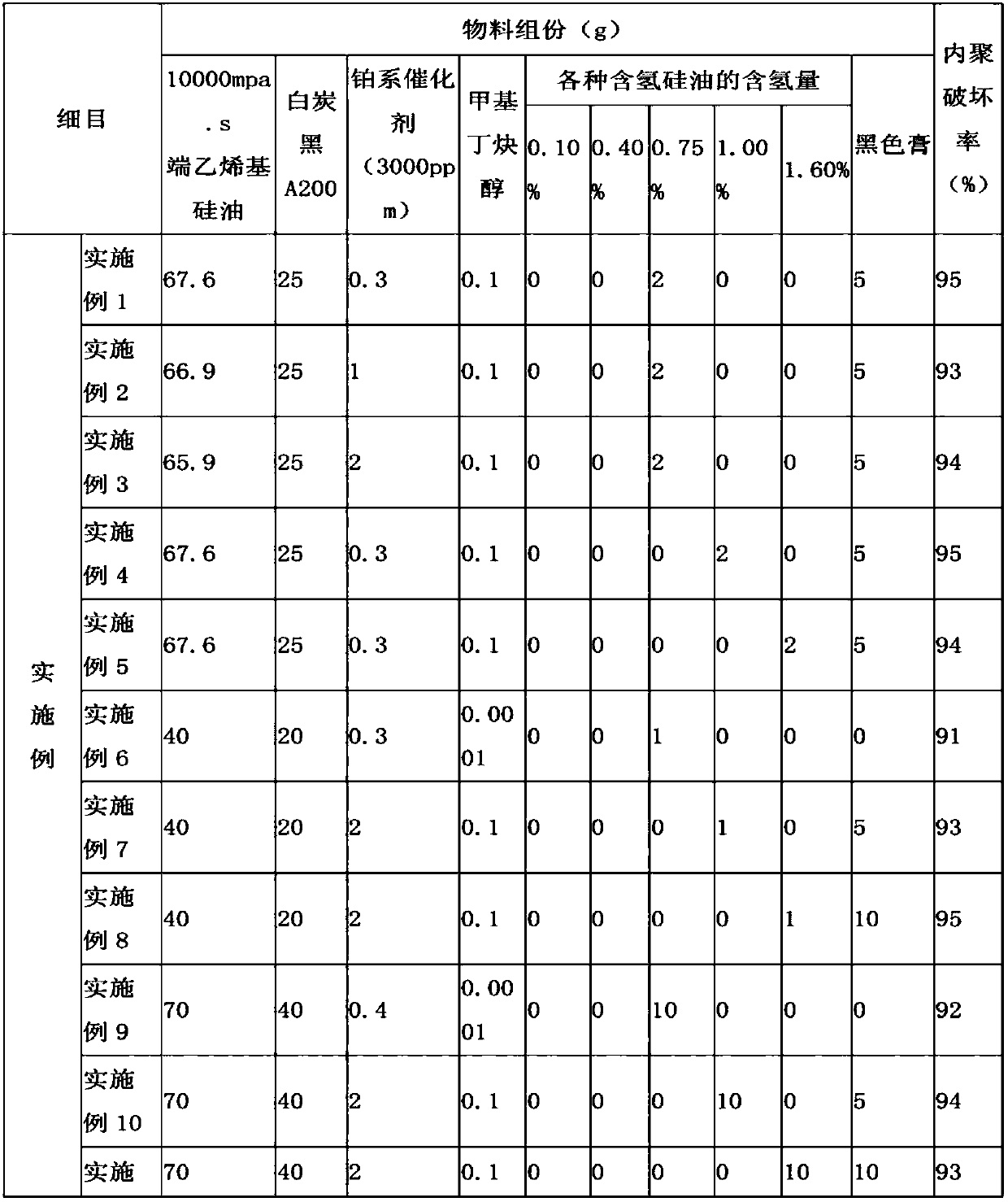

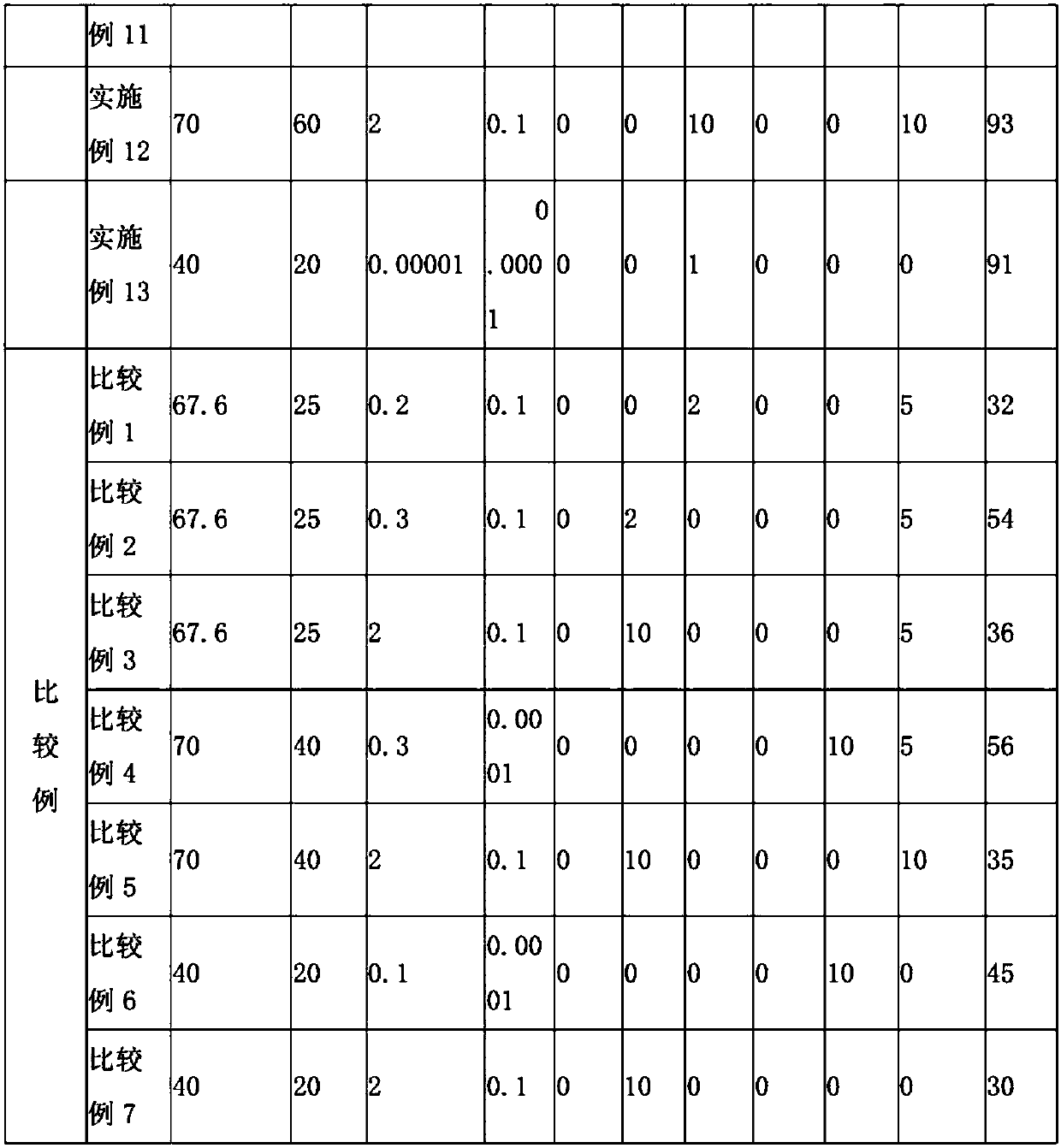

[0032] The composition and sub-weight of the specific silica gel raw materials are as follows:

[0033] Vinyl polydimethylsiloxane uses 10000mpa.s terminal vinyl silicone oil: 67.6g. It has been proved by experiments that vinyl polydimethylsiloxane contains at least two vinyl groups at the chain end or chain side and silicon The polydimethylsiloxane whose atoms are directly connected has the same effect as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com