PET(Polyethylene terephthalate) release film for OCA (optically clear adhesive)

A release film and optical adhesive technology, applied in the direction of adhesive, film/sheet release liner, coating, etc., can solve the problems of unsatisfactory waterproof performance and wear resistance of the release film, inconvenient for users to use, etc. The effect of light release force, improved waterproof performance and good tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

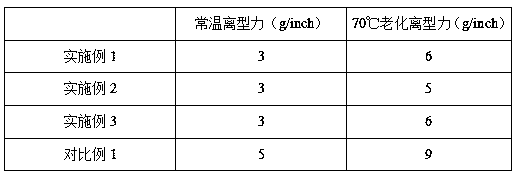

Examples

Embodiment 1

[0017] The release agent is composed of the following raw materials by mass: 30 parts of polyurethane resin, 22 parts of butyl acrylate, 20 parts of polyethylene glycol, 18 parts of nano-silica, 12 parts of silicon oxide, 16 parts of aluminum oxide, and 14 parts of polyethylene wax powder 15 parts of polyethylene, 13 parts of polyurethane, 11 parts of polyimide, 7~16 parts of calcium stearate and 9 parts of additives.

[0018] The auxiliary agent is composed of the following raw materials by mass: 18 parts of curing agent, 14 parts of antistatic agent, 13 parts of plasticizer, 11 parts of antioxidant, 9 parts of thickener, 8 parts of defoamer, 5 parts of silane coupling agent and 3 parts of toughening agent.

Embodiment 2

[0020] The release agent is composed of the following raw materials by mass: 37 parts of polyurethane resin, 30 parts of butyl acrylate, 27 parts of polyethylene glycol, 22 parts of nano-silica, 17 parts of silicon oxide, 20 parts of aluminum oxide, and 19 parts of polyethylene wax powder 22 parts of polyethylene, 16 parts of polyurethane, 13 parts of polyimide, 12 parts of calcium stearate and 15 parts of additives.

[0021] The auxiliary agent is composed of the following raw materials by mass: 22 parts of curing agent, 21 parts of antistatic agent, 16 parts of plasticizer, 14 parts of antioxidant, 13 parts of thickener, 12 parts of defoamer, 7 parts of silane coupling agent and 5 parts of toughening agent.

Embodiment 3

[0023] The release agent is composed of the following raw materials by mass: 45 parts of polyurethane resin, 38 parts of butyl acrylate, 34 parts of polyethylene glycol, 26 parts of nano-silica, 23 parts of silicon oxide, 24 parts of aluminum oxide, and 25 parts of polyethylene wax powder 30 parts of polyethylene, 18 parts of polyurethane, 15 parts of polyimide, 16 parts of calcium stearate and 18 parts of additives.

[0024] The auxiliary agent is composed of the following raw materials by mass: 26 parts of curing agent, 25 parts of antistatic agent, 19 parts of plasticizer, 16 parts of antioxidant, 17 parts of thickener, 15 parts of defoamer, 9 parts of silane coupling agent and 8 parts of toughening agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com