Solid phase-free microfoam drilling fluid and preparation method thereof

A technology without solid phase and drilling fluid, which is applied in the field of oil drilling, can solve the problems of difficult protection and discovery of oil and gas layers, blockage of gas and gas layer pores, long waiting time, etc., achieve good thermal stability and settlement stability, and suppress water The effect of dispersing chemical expansion and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

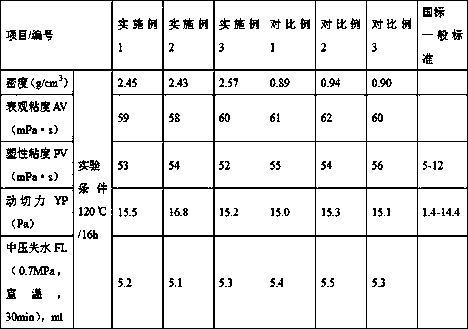

Examples

Embodiment 1

[0022] Weigh 50 parts of calcium carbonate (particle size: 200-250 mesh), 18 parts of formate, 90 parts of water, 0.3 parts of viscosifier, 4 parts of fluid loss reducer, 6 parts of lubricating and anti-slumping agent, and 2 parts of type regulator, 4 parts of foam stabilizer, 1 part of foaming agent and 2 parts of self-adaptive plugging agent, add them to the mixer in turn and stir at normal temperature and pressure, stirring speed 100-150r / min, stirring time 2- 5h, the finished product is obtained.

Embodiment 2

[0024] In parts by weight, 55 parts of calcium carbonate (particle size: 200-250 mesh), 15 parts of formate, 95 parts of water, 0.5 parts of viscosifier, 5 parts of fluid loss reducer, 6 parts of lubricating and anti-slumping agent, flow pattern adjustment Add 3 parts of foam stabilizer, 4 parts of foam stabilizer, 2 parts of foaming agent and 1 part of self-adaptive plugging agent, add them to the mixer in turn and stir at normal temperature and pressure, stirring speed 100-150r / min, stirring time 2-5h, That is the finished product.

Embodiment 3

[0026] Weigh 58 parts of calcium carbonate (particle size: 200-250 mesh), 19 parts of formate, 100 parts of water, 0.8 parts of viscosifier, 7 parts of fluid loss reducer, 6 parts of lubricating and anti-slumping agent, and 4 parts of type regulator, 5 parts of foam stabilizer, 1 part of foaming agent and 1 part of self-adaptive plugging agent, add them to the mixer in turn and stir at normal temperature and pressure, stirring speed 100-150r / min, stirring time 2 -5h, the finished product is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com