Film-forming plugging polyamine for drilling fluid, preparation method of film-forming plugging polyamine and drilling fluid

A drilling fluid and film-forming technology, which is applied in the field of drilling fluids, can solve the problems of incapability of simultaneous inhibition performance, film-forming plugging performance and compatibility performance, and achieves low energy consumption for catalytic reaction, good compatibility, and good film-forming sealing performance. The effect of blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

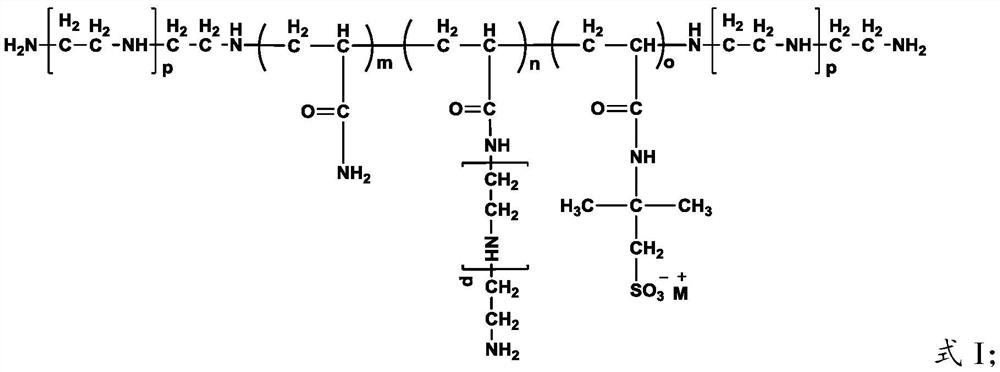

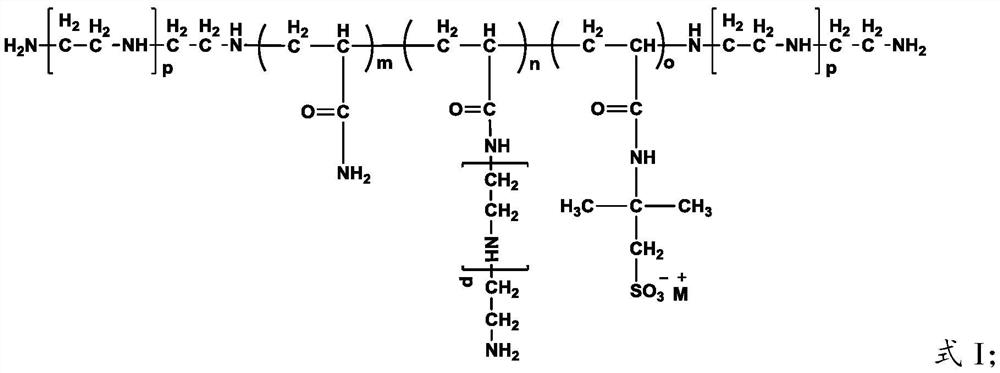

[0031] The invention provides a method for preparing a film-forming blocking polyamine for drilling fluid, comprising:

[0032] Carrying out a polymerization reaction of acrylamide, acrylic acid, 2-acrylamido-2-methylpropanesulfonic acid, water and hydroxide under the action of an initiator to obtain a copolymer;

[0033] The copolymer is reacted under the action of an amination reagent and a catalyst to obtain a film-forming blocking polyamine for drilling fluid.

[0034] In the present invention, the hydroxide is preferably sodium hydroxide or potassium hydroxide.

[0035] In the present invention, the initiator is preferably selected from hydrogen peroxide, potassium permanganate, ammonium persulfate, azobisisobutyronitrile or ceric ammonium nitrate.

[0036] In the present invention, the amination reagent is preferably selected from ethylenediamine, diethylenetriamine, triethylenetetramine, tetraethylenepentamine or pentaethylenehexamine.

[0037] In the present inventio...

Embodiment 1

[0051] Add 27g acrylamide, 28g acrylic acid, 12g 2-acrylamido-2-methylpropanesulfonic acid, 120g water and 16g sodium hydroxide into the polymerization reaction kettle, stir evenly at a stirring speed of 300r / min, and heat to 50°C, The pH value of the reaction solution was adjusted to 8 with a mass concentration of 40% sodium hydroxide aqueous solution, 0.5 g of hydrogen peroxide was added, and the polymerization reaction was carried out for 2 hours to obtain acrylamide / acrylic acid / 2-acrylamido-2-methylpropanesulfonic acid copolymer ;

[0052] Add 100 g of ethylenediamine to the above-mentioned acrylamide / acrylic acid / 2-acrylamido-2-methylpropanesulfonic acid copolymer, add 0.6 g of aluminum chloride, and react at a temperature of 130 ° C for 2 hours to obtain a light yellow transparent viscous The liquid is the film-forming blocking polyamine, and the product yield is 96.40%.

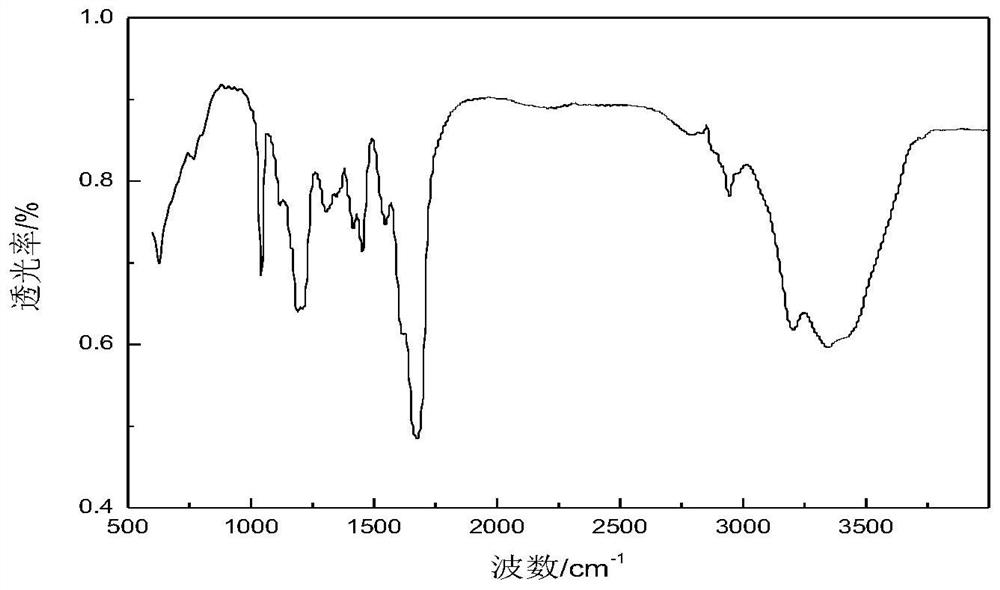

[0053] The product prepared in Example 1 of the present invention was subjected to structural det...

Embodiment 2

[0055] 27g of acrylamide, 30g of acrylic acid, 14g of 2-acrylamido-2-methylpropanesulfonic acid, 140g of water, and 17g of potassium hydroxide were added to the polymerization reactor, stirred evenly at a stirring speed of 500r / min, and heated to 60°C, The pH value of the reaction solution was adjusted to 9 with a mass concentration of 40% potassium hydroxide aqueous solution, 0.6 g of potassium permanganate was added, and the polymerization reaction was carried out for 3 hours to obtain acrylamide / acrylic acid / 2-acrylamido-2-methylpropanesulfonic acid copolymerization thing;

[0056] 110g of diethylenetriamine was added to the above acrylamide / acrylic acid / 2-acrylamido-2-methylpropanesulfonic acid copolymer, 0.8g of acetic acid was added, and the reaction was carried out at a temperature of 140 ° C for 3 hours to obtain a light yellow transparent viscous The liquid is the film-forming blocking polyamine, and the product yield is 96.89%.

[0057] The structure of the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com